|

THE CROSSETT STORY The Beginning of Forestry in Southern Arkansas and Northern Louisiana |

|

THE CROSSETT STORY

The Beginning of Forestry in Southern Arkansas and Northern Louisiana

R. R. Reynolds

IN THE BEGINNING — "CUT OUT AND GET OUT!"

Sawmilling of the virgin shortleaf and loblolly pine timber in southern Arkansas and northern Louisiana began on a large scale in the 1890's. Mills cutting upward of 50,000 bd. ft. per day were common, one was located 30 to 40 miles or so in every direction. Because of the many logs needed every day and the fact that logging trucks were unheard of, all large-scale logging was done by railroad. Generally, two spurs were constructed off the main-line into each 40-acre area, and teams of oxen or horses were used to skid the logs to the spurs. Here logs were picked up, by steam-operated loaders that ran on rails on top of the log cars, and placed on the log cars for transportation to the mill (fig. 1).

|

| Figure 1. - Sawmill #1, power plant, log pond, and log ramp of Crossett Lumber Co. Mill housed two high-speed band mills. (FS 394380). |

Although some stands of timber had as much as 25,000 bd. ft. (Doyle) per acre, the average that was usable, by standards in use at the time, was about 7,000 bd. ft. (fig. 2). This was according to Levi Wilcoxon, longtime logging and woodlands Superintendent of the Crossett Lumber Company of Crossett, Arkansas.

|

| Figure 2. - Virgin loblolly-shortleaf pine-upland hardwood stand near Crossett, Ark., in 1934. Some of the larger trees were 34 to 36 inches in diameter. The young woman pictured is Christine Hendrix (Mrs. A. G. Jacobson). |

In any event, by the middle to late 1920's, the end of the big cut was near at hand, and by 1930 many of the mill-owners, who had come South after logging in the Lake States had been completed, started looking at the big untapped virgin stands of the West as the location for their next operations.

Many families had moved into the uplands of southern Arkansas and northern Louisiana, had homesteaded, and had established farms many years before the coming of the big sawmills. To these farmers, trees were something that had to be disposed of by cutting and burning before the areas were suitable for row crops. Since machinery for such operations was not available in those days, the farmers often welcomed the big sawmillers with open arms. According to an oft repeated story, the Crossett Lumber Company people set up a land office at the county seat in Hamburg, Arkansas, and offered $2.50 per acre in hard cash, for the farmer's timber or timberland. When word of this got out, small timberland owners by the hundreds hurried in to get rid of their extra land or timber before those "Damn Yankees ran out of the stuff."

In other words, as late as 1933 many people thought that timberland (or areas with trees) was wild and undeveloped land. It would be of real value only when the trees were cleared and the acres put into pasture or row crops.

When logging of the virgin timber began on a large scale, no one thought about developing the second-growth stands. Only one kind of lumber was worth anything for construction purposes: slow growth virgin. Second-growth trees were often rapid growth, and second-growth lumber was supposed to be practically worthless "because it would warp or shrink or twist." And it supposedly had very little strength. So even though the lumber companies only cut trees that were about 14 inches and larger in stump diameter, they made no attempt to keep the smaller pines and hardwoods from injury. Many of those were cut and used for ballast and rough ties for the spur logging railroads.

It was also a certainty that once the pine "slashings" had dried out they would catch fire, and a nice hot burn would kill a large proportion of these smaller seedlings, saplings, and poles.

Because of this and because there was no organized attempt to protect the woods from fire, it now seems amazing that many of the smaller pine trees came through the fires, began to grow at a rapid rate, and began to produce seed. Seedlings sprang up and some thin, but respectable, young pine stands with trees of many diameters developed on many of the areas that had been cut over 10 to 20 years previously.

Hardwoods, from sprout size up to about 20 inches d.b.h. (diameter breast high), had always been intermingled with the pine in virgin stands. Since such hardwoods had little or no value at the time, the ones that were not seriously damaged in the cutting of the big pine stands continued to grow and reproduce. So the new, young pine stands often contained as many or more hardwoods than pine—and many of these hardwoods were larger than the pine.

PROFESSIONAL FORESTRY COMES TO CROSSETT

For the few companies in the South that did not fold up when the virgin timber neared an end, the decision to manage their second-growth forest for timber production was a gradual one, evolving as a last resort. The Crossett Company was no exception.

Until about 1930, the Crossett Lumber Company continued to offer its cutover land for sale to farmers and others. The company also tried raising cattle on an experimental basis. It was decided that something of better grade than usual "range" cattle should be produced, so the company purchased a high-quality and very expensive bull from Iowa in order to improve the strain. The idea was good but the bull could not stand the ticks and the heat. The story was told that in hot weather they had to put him into a padded cell in the barn, with fans blowing on him from "before" and "aft."

Two areas were included in the cattle venture. One was located about a mile east of Crossett on the Unity Road (now U.S. Highway 82). The other area was at the northern end of the Prairie Du Butte in Louisiana. The cattle venture failed, but in 1927 some of the old Cattle Farm area east of Crossett was planted with pine trees. This was the first sizeable loblolly pine plantation in the area (fig. 3).

|

| Figure 3. - Crossett Lumber Co.'s cattle farm plantation of loblolly pine. Stand was 14 years old at the time of the photograph. |

Having tried in vain to find suitable uses for its "cutover," the Crossett Company probably was in a receptive frame of mind for most any idea when Prof. H. H. Chapman entered the picture. Prof. Chapman, who headed up the annual Yale University summer camp for forestry students at Urania, Louisiana, became interested in some of the second-growth stands that had developed on the Crossett Company holdings. With the aid of some of his students he inventoried some of these areas and suggested that perhaps the Company could make a second cut of logs on some locations once the cutting of the virgin timber had come to an end. In any event, he undoubtedly was responsible for creating an interest in "timber possibilities" in the minds of the owners of the Crossett Lumber Company.

The interest was great enough for Company officials to agree to the appointment of a professional forester, W. K. Williams, who over considerable opposition in 1926 and early 1927 put through a proposal to start leaving pine seed trees (called "mammy trees" by the saw crews) at the time the virgin timber was being cut. He also began trying to interest the local people in fire protection for the woods. This latter proposal was of mountainous proportions because all the folks knew that the woods had to be burned over every few years "in order to kill the snakes and the ticks" and to "green up the grass."

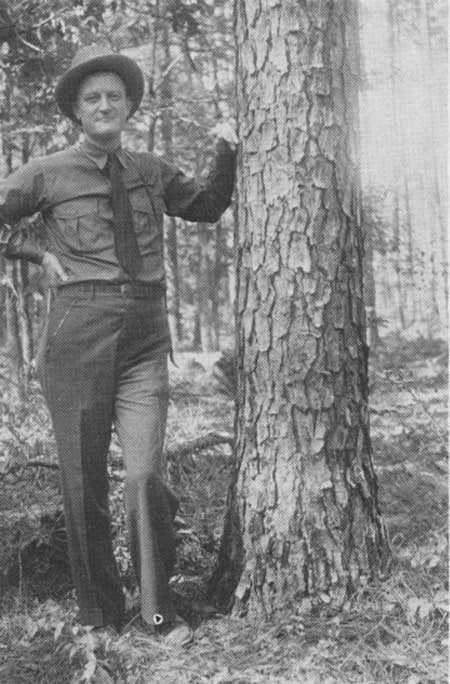

Williams resigned from his position after about a year to become Extension Forester in the Washington Office of the Department of Agriculture. He was replaced in March 1927 by A. E. (Wack) Wackerman, who was a forestry graduate of the University of Minnesota and of Yale University (fig. 4). According to Wack, he went to work under the general direction of Prof. R. C. Bryant of Yale University, who had been employed as consultant in forestry matters by the Crossett Company. He was to correlate his work with Levi Wilcoxon, who at the time was logging superintendent. Levi had foreseen the need for fire protection on company timberlands and had built five firetowers in strategic locations on Company lands. These had been connected with a telephone system. Wack reported that the towers were "in, but not working because no one had ever had experience or training in fire protection before." Thus, one of his first major jobs was to set up a fire protection system and to get it working. His second big assignment was to carry out a cruise of two of the blocks of older cutover lands to determine (1) the amount of second-growth pine and hardwood present, (2) growth and mortality, and (3) the amount of virgin timber remaining. He would then prepare possible management and cutting plans.

|

| Figure 4. - A. E. (Wack) Wackerman, second forester for the Crossett Lumber Co. Wack had much to do with the successful adoption of forest management for the Company's stands. |

THE U.S. FOREST SERVICE COMES TO CROSSETT

When I joined the Southern Forest Experiment Station in July, 1930, fresh out of the University of Michigan School of Forestry, many of the large southern mills had closed and more were closing every month. The production of lumber had been largely taken over by small, "peckerwood" mills that could be easily moved from place to place, and logging could be done by two or three pairs of mules or horses. It was agreed almost universally that the South would soon be out of the large volume, large-sawmill business, and few had any idea as to what would, or should, happen to the "cutovers."

Because of this situation, the Southern Station's economics division, to which I was assigned, was devoting most of its time to "Forest Economics Studies." The objective was to inventory the timber and timberland in a county, determine the growth possibilities, estimate the amount of abandoned farmland that could be planted to trees, assess the volume of forest products still being produced, and approximate when the remaining sawmills and other wood-using plants would run out of raw material and have to close.

The Station also felt that one of its main thrusts should be to attempt to help save as many of the forest industry operations as possible. This included cooperative agreements with industries to help inventory various company forests (when invited to do so); to help work out management plans; to do mill-scale and other research studies; and to determine what kind of logs could be profitably handled by the existing utilization plants. These agreements were called "Case Studies." It was felt that results from one study could be used by other companies or timberland owners with similar type stands and problems.

The first Case Study was with the Ozark-Badger Lumber Company at Wilmar, Arkansas. Information was gathered on volumes of merchantable pine and hardwood per acre and data needed for local volume tables were compiled. Information on annual growth and mortality were computed. Most important, a plan of management was suggested that would allow a harvest of logs for the company sawmill, at the same time that the growing stock on the company's forests would be gradually improved and increased. The objective was to help show how it might be possible for this company not only to stay in business but to increase the production of logs, lumber, and other products on a sustained yield basis.

Field work on the Ozark-Badger case study, undertaken during the period of April 27 to May 20, 1932, was largely performed by Art Spillers and myself. Assistance was given by James Daniels, who was mill and logging superintendent of Ozark-Badger, and by L. K. Pomeroy, co-owner of the company, who was later to become famous as a timberland owner and forestry consultant. Overall supervision of the work was by I. F. Eldridge, head of the economics division staff.

Meanwhile, effects of the great depression that started in 1929 were being felt by the southern pine lumber industry generally. Both price and demand for lumber dropped alarmingly. The Crossett Lumber Company, among many, moved to meet the challenge to their existence by cutting costs drastically, including salaries of their forestry personnel, by 50 percent. This did not stop the balance sheet from showing red ink, and in desperation the Company management cut some salaries, including Forester Wackerman's, by another 50 percent a year later.

After such drastic reductions in salary, Wackerman was more than willing to accept an offer of employment on the staff of the Southern Station, and he was assigned to the economics division. He made the transfer early in 1933 and was headquartered in New Orleans.

Wackerman's previous inventories of the older second-growth stands at Crossett had indicated that the Company might be able to continue sawmill operations on a reduced scale if it made some radical changes in operating policy. Because lumber from fast growing second-growth shortleaf-loblolly pine was not readily saleable, Wackerman had thought that Crossett might "stretch out" the cut of the last 25,000 acres of virgin, culled virgin, and advance second-growth timber. They could then have, for several years, some "cream" high-grade lumber from the virgin stands to go along with the "skim-milk" lumber from the second-growth.

As was mentioned earlier, the Forest Service was willing and anxious to assist any timberland owner who was interested in working toward sustained yield production of forest products. And the Crossett Company seemed a fine example of a company that might well benefit from cooperation with the Government. Thus came about the second case study the station undertook to help private industry attempt to move into the entirely new second-growth forestry or forest management field.

The Southern Station entered into a cooperative agreement with the Crossett Company, under which the station would provide technical personnel to mark one or more compartments of the remaining 25,000 acres mentioned above, known as the "East Block."

Before leaving the Crossett Lumber Company, Wackerman had cruised this East Block area, had made a growth study, and had prepared volume tables for the virgin and advance second-growth stands. He had determined that, if the 25,000 acres was divided into 10 blocks of about 2,500 acres each, one block could be cut each year on a light selection cutting basis, and would yield from 8 to 10 million bd. ft. of logs. Growth would be such that 10 years hence the merchantable volume would have grown back to the original amount and another cut could be made.

I was chosen to handle this marking job and I arrived, with my wife Geneva, in Crossett on August 13, 1933. Field work started immediately, as preliminary arrangements had been made to use five boys from a local Civilian Conservation Corps (CCC) camp. Because this was the first large-scale marking of timber on a selection basis in the region, we decided to keep more detailed records than would normally be required. All cut and leave trees were measured, and cut trees were marked with paint at the time of measurement. The record was by one-inch diameter classes, and the tally was by diameter and number of 16-foot logs.

It might be of interest to note that the strictly virgin timber was marked to a guiding diameter limit of 24 inches and oldfield timber to 17 inches. These limits were flexible, however, and any trees below these limits were marked for cutting if defective or very limby, or if the stand needed thinning in a particular spot. Fast growing and high-quality trees above these limits were left to compensate for the trees below the limits that were taken. Marking of the first unit was completed November 10, 1933.

THE BEGINNING OF SELECTIVE CUTTING AND MANAGEMENT

As the end of the virgin timber approached throughout the region, nearly all concerned with logging agreed that railroads just could not be used for logging the second-growth stands. At least 2,500 bd. ft. (Doyle) of logs of good size would have to be cut per acre to make it pay. The relatively small size of the second-growth logs would cause the costs per thousand board feet to soar. Furthermore, only a few of the trees in the many-diametered, natural second-growth stands were large enough to cut for logs. Seemingly, what was needed was a system of stand management and harvesting that would allow light cuts per acre and, at the same time, permit the remaining trees to develop into merchantable sizes. This pointed to the need for trucks.

Although they were very crude compared to today's models, a few trucks were being used by a few small mills. Could trucks be depended upon to produce a reasonable volume of logs for the large mills? And could such transportation be used for light harvests in second-growth stands?

The Southern Station was interested in this problem because it was a common one for nearly all mills in the South in the early 1930's, but the station had no funds for undertaking such a study. I was encouraged to apply for cooperative funds from the Charles Lathrop Pack Foundation for a "Selective Logging Study," which was approved in the late summer of 1934. Second-growth natural shortleaf-loblolly pine-hardwood stands owned by the Crossett Lumber Company were used for the study. The objective was to selectively log blocks of timber that had been marked for the removal of various volumes of pine and hardwoods, and determine the costs of felling, skidding, loading, hauling, and sawmilling.

The selected area was located about 5 miles southwest of Fountain Hill, Arkansas. Work on survey of block boundary lines and inventory of stands began September 5, 1934.

The trucks were gasoline powered and were used in combination with small two-wheel trailers (fig. 5). Both truck and trailer were equipped with 32 in. x 6 in., high-pressure tires. Loading was cross-haul with horses.

|

| Figure 5. - A truckload of pine logs produced on the Charles Lathrop Pack Selective Logging Study area near Fountain Hill, Ark. Note the 32 in. x 6 in. high pressure tires and the team of horses hitched to the front of the truck to help it out of the woods. CCC crewman was keeping records on volume per load and time required for loading and hauling. |

On November 5, 1934, with help from our five-man CCC crew, I began marking trees in the first block to be logged near Fountain Hill. To learn time-study techniques and work out procedure problems, we chose a fairly old "oldfield" stand that was marked for a rigid 17-inch diameter limit harvest.

Trees and logs were cut with cross-cut saws, skidded a short distance to truck-loading points by horses and loaded by horse cross-haul onto trucks. They were then transported to a large log storage area on the company's A.D.&N. Railroad (Ashley-Drew and Northern Railroad, locally known as the "All-Day And Night Line" because it usually took all day and part of the night for the train to make a round trip from Crossett to Monticello, Arkansas, a distance of 45 miles) (fig. 6).

|

| Figure 6. - Crossett Lumber Co. log train with a load of second growth shortleaf-loblolly pine and hardwood logs from the Pack Selective Logging Study. (FS350903). |

As soon as all the logs — they had to be produced in 1934 before the winter rainy season started — had been cut they were loaded on railroad log cars and transported to the mills in Crossett for mill cost and lumber out-turn studies.

Each log was marked with tree and log number and time cost studies were made of each stage of the operation. Lumber out-turn, grade, and value were computed for each log and each tree. Thus, it was possible—after the field work and sawmilling were completed in 1935—to summarize costs and returns for trees of various sizes and for the amount cut per acre from the various test plots.

On October 1, 1935, field work on the main part of the study got underway. On this portion we planned to cut, on an improvement selection basis, about 2,000 bd. ft. (Doyle) of pine and 1,000 bd. ft. of hardwood per acre from 40 acres; 1,000 bd. ft. of pine only per acre from 80 acres, and 500 bd. ft. of pine only per acre from 80 acres. All logs would be numbered and handled as before, and time studies of all phases of the operation would also be made as before.

The field work was completed November 25, 1936. Although the analysis of the mass of information obtained and the final report would not be completed for about 2 years, much very valuable information was available. Since this was the first study of its type in the country, the demand was great for tables, data, and articles of all types. Among these was a local volume table for second-growth, natural shortleaf-loblolly pine by d.b.h. and log length. This was probably the first such table for the South. A local board-foot volume table for second-growth upland-hardwoods was also produced. Data on yield by grade of lumber obtained from the second-growth trees and logs of various sizes were in great demand. Data on cutting, skidding, loading, and hauling costs for second-growth shortleaf and loblolly pine stands cut on a selection basis were also of great interest to many foresters and timberland owners interested in future forestry ventures. Many special compilations of data were made for many people and several articles on the general subject of "Good Lumber From Second-Growth Southern Pine" and "Good Forestry is Good Business" were written. And at the same time, we were covered up with visitors who were interested in details of the method of timber inventory, determination of allowable cut, and marking procedures for second-growth pine stands to be managed under the selection basis.

The final report on the Pack study found that small logs (8-inch to 10-inch top diameter and up to 18 feet long) of all grades and #3 and #4 logs (rough and knotty) of up to 16-inch top diameter were costing a company (such as Crossett) much more than they were realizing from the lumber produced therefrom. The study also indicated that, if the logs were of reasonable size and grade, it would be profitable to selectively log as little as 750 bd. ft. (Doyle) per acre. Further, if dense spots of small trees were thinned for pulpwood and most of the hardwoods about 4 inches and larger could be removed for logs, or acidwood, or were girdled, the lightly stocked second-growth stands could be put into fine shape for future management and growth.

THE CROSSETT RESEARCH CENTER AND EXPERIMENTAL FOREST

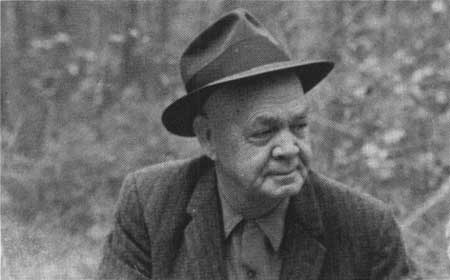

Before the marking of the first unit of the East Block was completed in 1933, the Crossett Lumber Company offered the Forest Service an area of about three sections of second-growth timberland to be used as an Experimental Forest and Research Center. Location could be anywhere on the company's holdings. So my notes for Friday, September 29, 1933, say, "Began looking over timberland for a proposed Experimental Forest." Wackerman joined in this search on October 14 and 15. And, starting on October 18, 1933, Director Demmon of the Southern Station looked over some of the possible areas (fig. 7).

|

| Figure 7. - E. L. Demmon, Director of the Southern Forest Experiment Station at the time that the Crossett Research Center was established. |

After final decision on the Experimental Forest location was made, first work of running out boundary lines was started on October 21, 1933. Before this, the Southern Station had carried on old-field pine growth and yield studies in cooperation with the Urania Lumber Company at Urania, Louisiana, and considerable work on planting and spacing of southern pine at Bogalusa, Louisiana, in cooperation with the Great Southern Lumber Company. The station also had research on naval stores production and problems underway at Lake City, Florida. But the Crossett Research Center was to be the first U.S. Forest Service branch research station in the South.

The area to be developed into the Crossett Experimental Forest contained mainly natural stands of shortleaf and loblolly pine that had developed unaided since the virgin timber had been cut to a 14-inch stump diameter limit in 1915. Stocking varied greatly from acre to acre from none to perhaps 5,600 bd. ft. (Doyle). Since little or no hardwoods had been cut at the time of the virgin-timber removal, nearly every acre had hardwoods ranging in size from new reproduction up to trees that were 24 inches in diameter. Many of the big hardwoods were post oak that had been in the virgin stands.

The Crossett Lumber Company gave the Forest Service 1680 acres of timberland outright. They reserved the timber but offered the Government a deal: if the station should return to the company in 20 years a volume of timber equal to the volume on the area at the time of the agreement, the land and the remaining timber would become the property of the Government.

By the end of 1933, it was agreed by the Director of the Southern Station that: (1) much of the early research would be on ways and means of improving and rebuilding the previously unmanaged second-growth stands, (2) the economics branch of the station would, working under the station director, have general control of development of the research facility, and (3) the day to day development and operation of the branch station would be under my direction.

We soon agreed that, to have good fire protection for the area as well as provide ready access for research purposes, roads should criss-cross the area at about half-mile intervals. To do this without funds was the trick.

At the end of 1933, work projects were being organized by the Government in order to give employment to some of the unemployed in the area around Crossett. The station applied for a Civilian Work Project (C.W.P.) for the road work, and this was approved December 16, 1933. Mr. Wilcoxon, logging superintendent of the Crossett Lumber Company, offered us three of his logging camp supervisory force and Ike Rawls, one of the camp log scalers who was to become timekeeper, scaler, and in charge of tools. Ike soon became my valued assistant, and he helped on the installation of nearly every research study over the next 40 years.

We began building a temporary shed and office on December 22, 1933, and started surveying and staking road lines (fig. 8). Also a unique feature of the road construction was that no machinery was available for the job—and none was wanted by the C.W.P. officials. The objective was to make use of the maximum amount of manpower. Thus we planned to build the roads entirely by hand—with shovels, picks, and axes. Roads were built 20 feet wide from ditch to ditch. We cut trees in the right-of-way flush with the ground and threw dirt dug from the ditches toward the center of the roadway in order to cover up the stumps (fig. 9).

|

| Figure 8. - First building of the Crossett Experimental Forest and Research Center. Building was used as tool shed and office until permanent office and other buildings were constructed. Building was built in December 1933. Russ Reynolds shown by building. |

|

| Figure 9. - Start of road construction on the Crossett Experimental Forest. Road cutting across picture in immediate foreground was the Crossett, Ark.-Bastrop, La. highway. |

Men were selected from relief rolls from the Crossett area and from as far away as Stillion on the Saline River, where the closing of a mill had stranded several families. Conditions were so serious that the Stillion group had to walk 8 miles down the Rock Island railroad to Crossett each morning, leaving Stillion at about 4 a.m. We would pick them up at the Crossett Filling Station at 7 a.m. each day. The men would put in a 10-hour day. Then we transported them back to Crossett, and they walked the eight miles back to Stillion. They would arrive at Stillion at about 9 p.m. Here their families would have some eats ready for them. They would later fall exhausted into bed. Their wives would awake awaken them at 3 a.m. and they would start another long day. For all of this the men were paid $1.25 per day for a 4-day week.

Among the Stillion group was a black man by the name of Jasper Burns, who had a stiff leg caused by a mill injury to his knee. But stiff leg and all, Jasper made the long walk twice a day in order to stay alive. Jasper became a valuable permanent member of the Crossett Research staff and worked for the Government until his retirement many years later.

Word that the Crossett Lumber Company was considering selection cutting of their last remaining virgin and advanced second-growth stands, and that the Southern Station had marked the first 2,500 acres for partial cutting spread throughout the country. Visitors by the dozens began visiting Crossett to see the first large-scale marking of timber on a selection basis, and to see development of the proposed Forest Research Center. My diary for May 26, 1934, reads as follows:

"Went to Collingston, Louisiana, to pick up Mr. Demmon (Director of the Southern Station) and Mr. Watzek (one of the owners of the Crossett Lumber Company). Talked over future plans with Mr. Demmon in a.m. In p.m. with Mr. Silcox Chief of the U.S. Forest Service), Mr. Demmon, Mr. Kircher (Regional Forester R-8), Mr. Watzek, Mr. Bryant (Prof. of Forest Utilization at Yale University and consultant to the Crossett Lumber Company), Mr. Trieschman (Member of Crossett's Board of Directors), Mr. Sonderegger State Forester of Louisiana), and Mr. Gillett State Forester of Arkansas), showing them the East Block selection marking, and the work on the Experimental Forest."

And the diary for Wednesday, July 18, 1934, reads: "With Wackerman and a Mr. McGowin (Julian) of the W. T. Smith Lumber Company (of Chapman, Alabama) whose company is thinking of practicing sustained yield on their operations."

But some of the Crossett officials still were not satisfied that the second-growth pine stands they proposed to log (along with the selectively marked virgin timber) had enough volume per acre to permit railroad logging. They, therefore, asked the Forest Service to assist in updating the stand and growth figures for their 146,000 acres of second-growth in the so-called NE and NW Blocks, located north of Hamburg and south of Monticello. They also asked us to propose a management and selective logging plan for the area.

Pete Downey, forester for the company, was to be in charge of the work. However, before the evaluation was hardly underway, Downey resigned and the work was temporarily halted.

The company's new forester arrived the first week of November 1934. He was Albin G. (Jake) Jacobson, a University of Michigan Forestry School graduate of 1929 (fig. 10). He was immediately assigned to the company's cutover land study.

|

| Figure 10. - A. G. (Jake) Jacobson, the Crossett Lumber Company's fourth Chief Forester, was responsible for establishment of the district forestry system and for getting the Company through many rough times—when they were attempting to change from virgin timber to second-growth management and harvesting. |

Early in 1935, the stand and growth data had been brought up to date. Average pine stand per acre on the 146,000 acres was as follows:

Volume 10" d.b.h. and above - 2,100 bd. ft. Doyle scale

Volume 12" d.b.h. and above - 1,852 bd. ft. Doyle scale

Volume 13" d.b.h. and above - 1,680 bd. ft. Doyle scale

Volume 14" d.b.h. and above - 1,461 bd. ft. Doyle scale

Volume 15" d.b.h. and above - 1,222 bd. ft. Doyle scale

At that time, we determined that at least 2,500 bd. ft. (Doyle) would be needed to make a railroad logging operation profitable. The size of logs that would be needed was unknown at the time, but it was quite obvious that logs produced from trees 10 to 12 inches d.b.h. would be very costly, especially if produced under a railroad operation.

To put it mildly, the company had doubts about the future of the sawmill business at Crossett. To attempt to make a go of it, they had agreed to a proposal to reduce their pine lumber production.

MEANWHILE—BACK AT THE FUTURE RESEARCH CENTER

Meanwhile, progress was being made at the future Research Center, but under considerable difficulty. Nearly all of the Southern Station staff were in favor of developing a headquarters area with office and housing for some of the technical and supervisory force. Also needed were telephones and electric service, additional road construction, graveling, and other improvements. But extremely little money was available for doing the work. By present day standards, when, with not too much effort, funds can be had for the building and equipping of a laboratory costing a million dollars, it seems amazing that the station could only find funds to build a small office and a small pump house. These were board and batten buildings with rough drop siding on the outside and knotty pine paneling on the inside. The office was built up on blocks with a crawl space underneath. It had a fireplace and a small bathroom. Construction of the office and pumphouse began in August 1934 and was completed in about 3 weeks, at a total cost of $2,400 (fig. 11).

|

| Figure 11. - Original office building at the Crossett Research Center Headquarters located about 8 miles south of Crossett, Ark., on the Crossett-Bastrop highway. Photo made in summer 1935. |

On September 24, 1934, work had begun on buildings to be used as winter quarters by the CCC crew, who was helping on a 100-percent inventory of timber on the Experimental Forest. Location stakes for a house, a filling station, and a four-car garage were set.

For other improvements, we had to scheme and beg and do the work with our own hands (fig. 12). We used the small crew of CCC boys from the Hamburg camp, not only to make the 100-percent inventory of trees on the new Experimental Forest, but to help survey the forty and compartment lines on the forest. They also helped drill a water well at the headquarters area, and cut brush from the fire lines that were to be constructed at quarter-mile intervals throughout the forest.

|

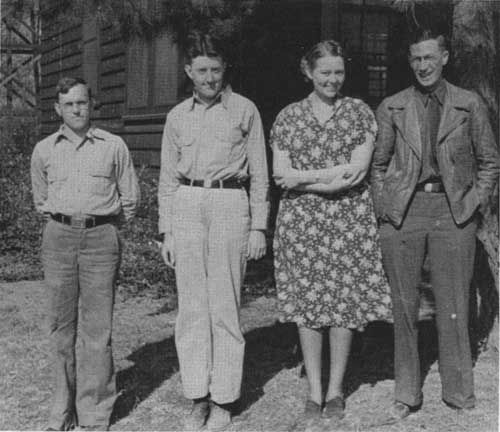

| Figure 12. - First staff of Crossett Experimental Forest in March 1938. Left to right they are A. G. Williams, Edwin Hughes, Lucille Futhey, and Russ Reynolds. |

By the end of 1934, much of the 13 miles of pick-and-shovel-built F.E.R.A. (Federal Emergency Relief Administration) roads were completed, and some of them had received a thin layer of gravel that we had loaded and unloaded by hand from a gravel pit 5 miles away.

The F.E.R.A. came to an end, but it was succeeded by the W.P.A. (Works Progress Administration). We obtained a project and a small allotment of funds for work on the Experimental Forest on July 29, 1935. The W.P.A. administration allowed us to "hire" some men with carpentry, log construction, and other skills, along with the allotment of those with only common laborer experience. The W.P.A. administration also provided us with a small amount of money to purchase needed lumber, nails, and other materials.

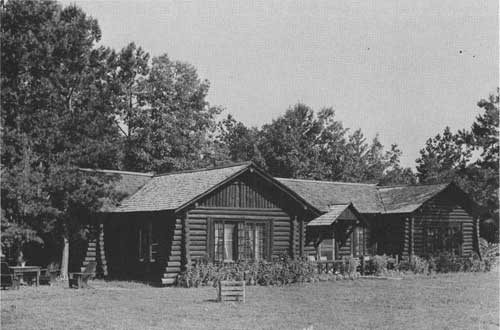

Since long pine poles of 10 to 12 inches butt diameter and with a little taper could be had for $1.00 and less per pole (if we did the cutting, peeling, and hauling) we decided to construct a custodian cabin and bathhouse, a superintendent's house, a forester's residence, a four-car garage, and a filling station, out of logs. Rafters were made out of small, round pine poles. Roofs were covered with cypress shakes produced by our crew from old, generally hollow, cypress trees given to us by the Crossett Lumber Company. Pieces of 2 x 4's and 2 x 6's were set against the logs on the inside of the rooms and pieces of knotty pine paneling were nailed to these. Dried, dressed #3 (knotty) boards were obtained for $17.50 per M bd. ft. If such boards were selected for sound knots, the price was $22.50 per M bd. ft. And if each side of the board was bevelled so as to produce a "V" joint when construction was completed, the cost was $27.50 per M bd. ft. (fig. 13).

|

| Figure 13. - Mid-construction of the resident forester's building at the Crossett Research Center. Is it likely to ever make a house? |

In those days power tools were not available, so all cutting of the trees and logs for the buildings had to be accomplished by the use of two-man crosscut saws and axes. Fitting of the logs at the corners of the buildings had to be done by trial and error by the use of axes and large chisels. Concrete for supporting walls and cellars had to be mixed by hand in 4 x 8 feet troughs, with gravel and sand loaded, hauled, and screened by our crews from local pits.

Construction of the various log buildings started on September 30, 1935, and was largely completed by the middle of the summer of 1936. To give one an idea about "building without money," by far the most expensive of the construction jobs was the forester's residence (fig. 14). This was a 50 x 58 feet (inside measurement) H-shaped house with a basement, hot-water heating system, and fine hardwood floors in most rooms. Total cost of all logs for the house was $108 (standing tree value), and total cost of the house was less than $7,000, including labor. Except for a small amount of architectural and supervisory help, the total cost of all these original log buildings to the Southern Station was only a few hundred dollars.

|

| Figure 14. - The completed house in 1937. It had a 18 ft. x 25 ft. living room, a 16 ft. x 18 ft. dining room, a large kitchen, two bedrooms and a sleeping porch, a bath, a laundry room, and a cellar. (FS 350851). |

As this construction work was getting underway in summer 1935, the director of the Southern Station, the division chiefs, and some of the research personnel had a final meeting to agree on the assignment of research study areas on the Experimental Forest. The result was that 80 acres was to be left untouched as a "Natural Area"; 30 acres was for a native tree Arboretum (fig. 15); 80 acres was for farm forestry studies; 280 acres was to be set aside for small plot, "test tube", or fundamental studies; 880 acres was for large compartment studies; and 330 acres was for administrative use and for later assignment.

|

| Figure 15. - Planting tree arboretum on the Crossett Experimental Forest during the spring of 1935. Timber stand in the background is typical of the unmanaged second-growth stands that were present on the forest when research began in 1935. |

MORE GROWING PAINS

The winter of 1934-35 was not unusually cold, but we learned that, though fireplaces are nice to look at, they are not exactly the way to heat an office. Especially if much inside work is to be done. So we talked someone into providing enough money for a small, wood- and coal-burning, circulating, gravity-flow, hot-water furnace. The only thing wrong with that was that we needed a cellar for it. But that didn't stop us. Some of us began acting like moles, and with short-handled shovels we crawled under the office and started digging a cellar without disturbing the footings of the building. In short order we had our forms in and concrete mixed and poured. We bought used pipe and radiators and, before the end of January, we had lots of wonderful heat.

We had no money for coal to fire the furnace, but we did have an unlimited supply of good hardwood for the cutting. So, we used wood. Unfortunately, though, the fire had to be stoked at midnight and at about 4 a.m. if we were to have a warm building when it was time for the office staff to go to work in the morning. As the boss, I would not dare ask someone else to do the nighttime stoking of the furnace, so I did it at the same time that I fed the furnace in the big house. But in those days one had to do many "extra" jobs in order to keep the project going.

There was no problem getting all the female W.P.A. help we needed for work on the mass of time-study and yield data collected on the Pack Selective Logging Study—if we had some tables, chairs, and desks. We learned that the Veterans Hospital at Alexandria had some used office furniture that they were willing to give us. To this we added two large tables that we built from glued sections of 1 inch x 1-1/2 inches x 8 feet red oak, white oak, and post oak. These were massive and heavy tables but beautiful when sanded, smoothed, and finished with natural varnish. They were still around in 1970.

THE BEGINNING OF PARTIAL CUTTING ON CROSSETT LANDS

The cutting of selectively marked virgin timber in the Crossett Company's East Block began in 1935. It was done under the same railroad logging system as was used when the virgin timber was clearcut. However, with the reduced harvest per acre the costs increased. By mid-1935 the company had also started some railroad logging of its second-growth in selected stands. Here, too, the low volumes of logs available per acre and the small size of logs caused production costs to skyrocket.

The company had begun making contracts with a few log contractors for the cutting of marked timber for delivery by trucks to the company's East Block main line railroad and to landings on the A.D.&N. Railroad at Monticello, Lacy, Fountain Hill, and Pugh, Arkansas.

THE FIRST USE OF TRACTORS FOR SKIDDING

Until this time, all skidding of logs at Crossett and in the region was accomplished with the use of horses, mules, and oxen. Between late spring and late fall it was usually possible for trucks to drive directly to the logs in the woods, so the teams only had to bunch one or more loads in a spot. In wet weather, however, trucks had to stay on the very few hard surface roads, and skidding had to be to these roads. With railroad logging where there were logs of up to 500 bd. ft. each, skidding an average one-eighth of a mile was a real problem, any time of the year, even though two-wheel "bummers" were used to carry the front end of the logs. During long periods of wet winter weather it was almost an impossibility. Tractors for use in skidding logs in the woods were unheard of.

At this time the Caterpillar Tractor Company had crawler tractors that were sold for use around building projects. Since the log skidding problem was a universal one, it was thought that tractors of this type might be used for winter logging and, in fact, anywhere that skidding distances were long at any time of year. Consequently, after several conferences and planning sessions, we decided to undertake a tractor skidding study in the East Block area, where logs would be skidded to a railroad landing. It was a time and cost study to determine the number and volume of logs of the different sizes that the tractors could carry per trip. We also computed the cost per M bd. ft. for different distances of up to a half-mile. The study got underway in the spring of 1936 with Robert Worthington of the Southern Forest Experiment Station in charge. He used a crew of CCC boys to collect the necessary time and volume data.

The first of April was the date chosen for the start of the study since this is the time of the year when soil conditions are less firm and skidding of logs the most difficult. However, April 1936 happened to be one of these rare spring months when ground conditions were good and there was very little rain. Nevertheless, the study was undertaken as planned.

Relatively small RD-4 tractors were the first ones tested. It soon became apparent that, under dry conditions and for short distances, teams of horses or mules could skid logs at a cheaper rate than the tractors. It was also true that, for distances greater than about 400 feet, tractor skidding cost per M bd. ft. increased sharply with distance. This seemed to be true largely because the small tractors could not carry enough volume of standard length (12-20 foot) logs.

In an attempt to solve this problem it was decided to produce long logs (24 feet to tree length) with the stems bucked to regular length at the concentration point (or landing) next to the Company railroad. This reduced costs somewhat but not nearly enough.

Next, it seemed that larger tractors might be desirable and cheaper, per M bd. ft., because of their greater power. So two tractors, an RD-6 and an RD-7, were shipped in for study. They could and did pull a much larger load of tree length logs, especially when skidding pans or arches were used to carry the front end of the logs off the ground.

Another important finding was that the skidding cost varied with the size of the average tree or log, partly because of the volume of the average load that could be carried and partly because of the extra time required to assemble a load of small logs.

Finally, we found that under no set of conditions could the tractors tested skid logs a distance of one half mile or more at an acceptable cost.

Later studies under winter or wet weather conditions, when soil moisture was high, indicated that tractors could be depended upon to move logs from stump to loading point when team skidding was impossible. Also, tractors could be stuck and almost buried on certain soils, requiring much loss of production while they were being dug out. Nevertheless, tractors were in the woods to stay.

A FULL-BLOWN CRISIS DEVELOPS

While all these projects and studies were underway, a full-blown crisis developed at the Crossett Lumber Company. The Company was still operating in the "red" at the end of 1935, and Company directors told Mr. Arnold (the general manager) that, unless he could get the Company operating profitably before the year was out, the directors would have to change managers—and perhaps some other personnel.

Mr. Arnold in turn called in Albin Jacobson and said, "you damn foresters got us into this mess, now you had better get us out." Jacobson had a good idea as to what the trouble might be, but he asked the Director of the Southern Station for help in solving the problems. The Director ordered "all steam ahead." Because it was a hardwood log utilization problem as well as a pine log problem, the Director asked John Putnam, hardwood expert for the Station, and myself to assist Jacobson.

First, the hardwood utilization problem was tackled. The company had some years earlier, purchased a considerable acreage of virgin Ouachita River bottom hardwood land located in the flood plain adjacent to and east of the river (fig. 16). The site was quite poor. Most of the volume was overcup oak, and the trees, although of good size, contained only about 1-1/2 logs per tree. Mineral stain was quite common in the wood. The company had overestimated the volume and quality present on the area, and was attempting to make up for this by cutting and sawmilling many logs of doubtful value.

|

| Figure 16. - Ouachita River bottomland in July 1937. This is a typical virgin hardwood stand of Tensas Delta country of Arkansas and Louisiana, overmature and defective. (F5350894). |

Based on Putnam's knowledge of quality yields of lumber to be had from logs of various sizes and grades, and on observation of grade yields in the mill, a considerable volume of Ouachita River bottom logs that were banked along the company's logging railroad were classified into three grades. Class 1 logs were those that obviously would be profitable to log and mill. Class 3 logs were those that obviously were unprofitable because of rot, large knots, small size, and other reasons. Class 2 logs were those that were questionable as to profitability.

Many logs from each class were sawmilled, and we recorded the lumber volume and grade. We also recorded the sawmill time per M bd. ft. of lumber yield. We determined logging and milling costs for logs of each class and subtracted this amount from the green chain value of the lumber. The end product was a figure representing net return per M bd. ft.

From the above study, we determined that the company was making a good profit on the Class 1 logs. It was breaking even or making a small profit on most of the Class 2 logs, but it was losing so much money on the Class 3 logs that the whole operation was unprofitable.

The problem was solved by the establishment of hardwood utilization standards for log production. Logs of various species, or species groups, had to have a certain size and log grade before they would be cut and brought out of the woods. The hardwood logging and milling was apparently never a very profitable operation, but this study and follow-up put it into the black.

After a short review of the pine operation, it appeared that the red ink in the financial statement was, like the hardwood problem, largely the result of too many unprofitable logs being brought into the sawmill. To try and produce the large volume of logs necessary to keep the two large mills running, the woods division was scratching for all the logs they could get. In marking of the East Block virgin timber, trees with heartrot and others that were very limby and low grade, along with many very high-grade trees, were spotted and later cut for logs. Many of the trees with heartrot yielded large logs but generally with only a thin layer of solid wood toward the outside. The rest of the cross section had rot in various stages, and from this only unprofitable Grade 4 lumber could be produced. Many logs from the tops of high quality trees and from the whole stems of very limby trees produced logs with very large knots, and often boards with loose knots.

In cutting the marked and unmarked second-growth stands, many small logs were produced, as well as many logs with large knots. The Pack Selective Logging Study—and the follow-up mill-scale-study—produced yield, cost, and lumber value data for the various sizes and grades of such logs. A summary of this data gave all the information needed to indicate what kind of logs would be profitable and what kind unprofitable for sawmilling at Crossett.

Little data, however, were available on lumber out-turn from the large rotten-core logs from the virgin stands. We ran a mill-scale study of a representative sample of such logs to determine the amount of defect that the logs could have before becoming unprofitable. A similar test was also run on top and rough logs to determine characteristics of the unprofitable ones.

From these studies, utilization instructions were prepared to help those who were responsible for log production keep most unprofitable logs out of the sawmill.

The application of such standards meant that many of the smaller and the rougher logs from small trees could no longer be used in the relatively slow, and relatively expensive, mills that had been designed for operation on large virgin logs. Much of the upper stem of the larger second-growth trees also had to be left in the woods.

FIRST RESEARCH ON THE CROSSETT EXPERIMENTAL FOREST

As has been indicated earlier, the second-growth pine-hardwood stands present on the new Experimental Forest contained many hickory and red, water, post, and white oak. Some of the post oak and a few of the other species were as large as 24 inches in diameter. Because of past fires, many large trees contained rotten centers, but a few were of the right grade and size to make merchantable logs. The hardwoods generally occurred singly, or two and three together, and interspaced among the pine. In many places, however, there would be an almost solid stand of hardwood, up to an acre in size, with pine reproduction, seedlings, and saplings underneath (fig. 17).

|

| Figure 17. - Low quality hardwoods, most of which had been left at the time that the virgin timber was cut 15 years earlier, had taken over this pine site on the Crossett Experimental Forest by 1935. (FS 350923). |

If we were to intensify management of the stands and increase yields and returns, we somehow would have to reduce greatly the hardwood component of the forest. The use of hardwood for pulpwood in those days was unheard of. Many people burned hardwood for heating and cooking, but there was little market for the wood. If a person needed some wood he could have an unlimited amount from company land just for the cutting.

Fortunately, Crossett had a so-called "charcoal plant" that had been built to use cutoffs and trimmings from their hardwood sawmill. Because of trouble with uniform carbonization of this material, they had started using small round and split sections from the trees in the woods. The sections were 52 inches long, and could not be over 5 inches across on any face. In those days it was said jokingly that the company "would take any hardwood species—as long as it was oak and as long as the piece contained few, if any, knots." But the cutting of "chemicalwood" provided a market for some of the unwanted hardwoods (fig. 18).

|

| Figure 18. - Hardwood "chemicalwood" stacked in the woods for drying. |

Because of this, our first "study" undertaken on the Experimental Forest dealt with improvement cutting. The Crossett Lumber Company had agreed to take all of the chemicalwood we wished to produce, so we decided to determine how much of the product the previously unmanaged stands would yield per acre, how much it would cost to produce the product, and how many trees unsuitable for chemicalwood we would have to girdle. We acquired a couple of used 1-1/2-ton trucks and built chemicalwood racks on the back of each. We then picked several men out of our E.R.A. crew with woods experience, and went to work on the several compartments that had been marked previously for the study. In those days the market price for chemicalwood was $2.25 per "unit" (52 inches wide x 4 feet high x 8 feet long) of wood delivered to the chemicalwood yard in Crossett. We did not make a lot of money, but we put a lot of hungry men to work and we greatly improved the growing conditions and pine stocking on the areas treated. Later we applied the practice to nearly all the Experimental Forest that was to be used for compartment studies.

DEVELOPMENT OF A MARKET FOR PULPWOOD

Two kraft paper mills had been built at Bastrop, Louisiana, in the 1920's, and both used pine for raw material. However, their requirements were relatively small and could easily be met locally. The Crossett area had no market for its pine or its hardwood from trees that needed to be removed in thinnings, or from tops of trees that had been cut for logs.

It is not known when Crossett Company officials started thinking about the possibility of building a pulpmill in order to use this material. But it was possibly by 1933 when the company's forestry program started to take shape. By June 7, 1935, the discussions had gotten to the point that they engaged Spain and Company, Consultation Foresters, of Memphis, Tennessee, to make a check cruise of their pine timberlands to determine how much material might be available to a mill.

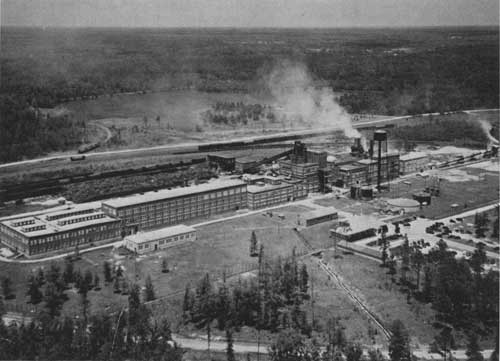

By February 1936, a secured loan from the Reconstruction Finance Corporation had been approved, largely because it would provide employment for many unemployed men in the area. Construction plans had been nearly completed for a 150-ton kraft mill, and the location for the mill had been chosen (fig. 19).

|

| Figure 19. - The Crossett pulp and paper mills—built in 1937 to utilize small trees removed in thinning and tops of sawlog trees. |

Things were stepping right along. My diary for Sunday, February 16, 1936, reports, "Spent the day with Director Demmon inspecting the Experimental Forest and the Experimental Forest buildings that were under construction. Inspected the Improvement Cutting study on the forest and looked over suggested pine pulpwood thinning study areas. Also looked over some of the Company's selective logging and the site for the new pulpmill."

In the western part of the shortleaf-loblolly-upland hardwood type, in Arkansas, Louisiana, Mississippi, and Texas, about 5 to 10 percent of the forest area was made up of dense, even-aged loblolly or loblolly-shortleaf pine stands. A few of such stands resulted from a severe fire or wind storm.

However, by far the most were "oldfield" stands. In the early years of farming, the owners of the farms would clear a patch of 5 to 20 acres of trees and brush, and plant the cleared patch to corn or cotton or other crops. Commercial fertilizers were unheard of, and the natural fertility of the fields would be reduced from year to year. After so long a time, the owner would clear up another field or two and abandon the worn-out fields. Generally pine seed from the surrounding forest would be blown into the abandoned patches, and a dense stand of young pine would result.

Until 1935 or thereabouts, there was much question as to whether these oldfield stands were a blessing or a hindrance. In most localities there was no such thing as a market for pulpwood. And there was only a very limited market for treated pine fence posts. If the owner wished to use such areas for grazing, he had the task of clearing the abandoned fields of the pine saplings and the new stems that continued to come m from natural seeding. If the owner of such thick patches of oldfield pine did nothing to them and the stands escaped a serious fire, as many trees as could survive the severe competition (among one another) would eventually reach pulpwood size. And finally many would reach small sawlog size.

But such stands still had little or no value. Until about 1938, an individual (if he had the money and a strong enough belief in the future) could have purchased hundreds of thousands of acres of such stands, with the equivalent of up to 35 cords of pulpwood per acre, for $5-$6 per acre. At one time I purchased 640 acres of such stands with loblolly pine of pulpwood size as thick as "hair on a dog" for $6 per acre. This included cost of land, the trees, and all mineral rights.

When many of the trees in such oldfield stands approached sawlog size, it was customary for the nearest sawmill owner to purchase such stands under a 20- to 30-year "timber deed." This meant that the purchaser would make an estimate of the volume of log-size material on the property and then get the owner to give the company 20 or more years in which to cut the stand. The price per M bd. ft. was often not more than $2.50. Because the estimated volume was based on Doyle scale and the sawtimber trees were small, the volume paid for amounted to very little. The purchasers of such stands would usually wait until the last year of the timber deed before cutting the stand. The result was that the purchaser would usually cut 2 to 10 times the volume and value that was paid for in the earlier years. Too, over the 20- to 30-year period, the owner of the land would pay the yearly taxes on the property—and he was expected to also keep fire and trespassers out of the timber stands.

GROWTH AND YIELD TABLES—CONCEPTS

The dense oldfield stands did have a useful place in the scheme of things. Shortly after the Southern Forest Experiment Station came into being in 1921, researchers had begun collecting data for the construction of growth and yield tables for fully stocked stands of the four principal species of southern pine—loblolly, longleaf, shortleaf, and slash. At the time, and even into the middle 1930's, "fully stocked" meant all the trees that one could have growing on a given area, on a given site, at a given time. For instance, it was assumed that a fully stocked stand of loblolly pine growing on an 85-foot site should have about 140 square feet of basal area at 30 years of age, because stands could be found with this amount of stocking. This concept was undoubtedly imported from Europe at the same time that the first European foresters came to the United States. In any event, work at the Southern Station resulted in a quite famous U.S. Department of Agriculture-Forest Service publication. It was known as Miscellaneous Publication No. 50. It presented the first comprehensive growth and yield figures for fully stocked stands of the four major southern pines. Such information was based on stand age and tree height or log length.

Stands of these pines that had basal areas less than that shown in the tables were considered understocked. Furthermore, in those days most foresters thought that the growing stock in "understocked" stands should be built up to this full volume in order to obtain maximum growth. This was held to be true for board-foot as well as for cubic-foot values.

Another interesting concept that held sway until the mid-1930's was that board-foot growth and cubic-foot growth per acre per year was directly related to percent of full stocking. If the stocking of a given stand was 50 percent of the full stocking, as shown in the growth and yield tables, the cubic- or board-foot volume growth would be 50 percent of the values for fully stocked stands.

JIM GIRARD

A few of us foresters did not agree with such a concept but it was James W. (Jim) Girard, a nonforester and nonresearcher, who proved that the idea was erroneous. Jim, who had been a timber cruiser and logging engineer in the western forests, had been hired by the U.S. Forest Service to help the Assistant Director of the National Forest Survey. Almost immediately, Jim clashed with the Director and other high-level Washington personnel in charge of the Survey. They had intended to publish data on the stocking and growth of an area of Florida's timberland (as I remember it) that had been inventoried by the Survey staff. Stocking per acre was only about 30 percent of that shown in the Miscellaneous Publication #50 growth and yield tables, so the point was to be made in the survey report that the growth was only 30 percent of normal.

Jim would not accept such a statement. He was positive that the growth would be greater than this. After many conferences and harsh words on the subject, Jim proposed a study of pine growth in relation to stocking. This was finally agreed to and was conducted in ponderosa pine stands of various stocking in Montana in about 1935.

Results of the study conclusively proved that Jim was right and that it was possible to have, say, 60 percent of maximum growth in stands with only 40 percent of full stocking as shown by the growth and yield tables. This finding was later proved correct at the Crossett Research Center and elsewhere, and led to the use of increment-core and permanent sample-plot studies to determine actual growth in understocked stands. It was also the reason that 100-percent repeat inventories were insisted upon in later compartment and small-plot studies undertaken at the Crossett Research Center.

This same Jim Girard was the idea man for the form-class volume tables he later developed in collaboration with Clement Mesavage, who at the time was on the staff of the Southern Forest Experiment Station. The first such publication had the title, "Tables for Estimating Board-Foot Volumes of Timber." For some unknown reason the publication was not given a number and was marked "For Administrative Use." It was never published for general use. The Southern Forest Experiment Station in 1947 did publish "Tables for Estimating Cubic-Foot Volume of Timber" by Clement Mesavage, which was based on the Girard form-class idea. Both Girard and Mesavage were disappointed that the Forest Service didn't publicly accept the Girard form-class tables and recommend them for general use.

THE PULPWOOD THINNING STUDY

Because of the initiation of a market for pulpwood, and because of the very slow diameter growth of trees on most of the heavily stocked oldfield (and some natural forest) stands, it seemed desirable to determine the effect of thinning in stands of this type. Thus, after much thought and planning, the second study to be undertaken at the Center was one on pulpwood thinning. It was begun on June 11, 1936. The objective was to determine the present and future yields, returns, and cost when: (1) about 200 of the best trees were reserved per acre on a spacing of 15 x 15 feet; (2) about 100 of the best trees were reserved on a spacing of 21 x 21 feet; (3) 70 of the best trees were reserved on a spacing of 25 x 25 feet; (4) 40 of the best trees were reserved on a spacing of 33 x 33 feet. In each case, trees smaller than 6 inches d.b.h. were not counted as crop trees and were allowed to remain on the plots.

At the time, to counter severe criticism of clearcutting, the Southern Pulpwood Association had a cutting "rule" that it urged its members to use. The association further urged its members to purchase pulpwood only from dealers, contractors, and timberland owners who cut in a manner that would equal, or be better than, the standard adopted. The minimum standard for pine pulpwood was to "leave all trees up to and including 7.5 inches d.b.h. and leave one 9.5-inch or larger tree every 50 feet." Such a treatment was included in the study. Also, uncut check plots were included, making six treatments in all. The study was undertaken in a 44-year-old oldfield stand with an average basal area of about 140 square feet per acre.

We found that the most net-cubic-foot growth for the first 10 years was on the plots thinned back to 200 trees per acre. The most board-foot growth was about the same on plots thinned back to 200 and 100 trees per acre, with the plots thinned back to 70 trees per acre not far behind. The uncut check plots were far behind in both net cubic and board foot growth.

SMALL-TOWN LIVING

Up until July 9, 1936, I and Geneva, my wife, lived in Crossett—first at the Rose Inn and then in a house on the southwest corner of the intersection of what is now Cedar Street and Third Avenue. The house was set aside for rental to Southern Station personnel.

The Rose Inn was a large three-story wooden structure with open walk-up stairways (fig. 20). It was Company owned and provided the only public overnight housing in town. It had a large lobby with a big fireplace and a long row of rocking chairs. Another long row of such chairs adorned the long, covered front porch. Rooms on the third floor were reserved for unmarried school teachers, who were required to live there. Not too much space was required since there was only one white and one black school in town. Crossett was very much off the main roads. In those days the rooms on the second floor usually could take care of visiting lumber company officials, plus two or three of the single men who worked for the company and did not have other housing. It also accommodated an occasional salesman and other visitors.

|

| Figure 20. - The famous Rose Inn at Crossett, Ark., 1934. |

The large Rose Inn dining room, always with sparkling white tablecloths on the tables and waiters with white jackets, was famous for its good food. For many years, men had to wear ties and coats before they were admitted to the room. To be reasonably sure that those who came without proper attire could have something to eat, Mr. Boardman, the hotel manager, kept a supply of extra coats and ties on a clothes tree just outside the room.

Geneva and I were allowed to live and eat at the hotel on a monthly rate that was similar to the one paid by the other regulars—$30 each per month. This included steak every night, if one wanted it, and always plenty of hot biscuits and many choices of potatoes and vegetables.

Crossett was strictly a lumber company town with all of the houses built, maintained, and owned by the Company (fig. 21). The houses were all built up off the ground on brick or concrete piers with plenty of crawl space underneath for the installation of piping and for reducing the problem of termites (fig. 22). No insulation of any kind was used, so the houses were very drafty and cold in winter. All buildings were painted the same color and many looked alike so one learned to know his house by some distinguishing feature in the yard. No yard was complete without a servant's quarters in back, and most homes "enjoyed" outside toilets.

|

| Figure 21. - Main street of Crossett, Ark., 1934. |

|

| Figure 22. - The Reynolds residence in Crossett from 1934 to 1936, a typical Crossett house at the time. |

Because of the low wages paid (by sawmills in general, including Crossett), most families kept cows and chickens to help make ends meet. There was no such thing as a stock law in those days. So, after milking time in the morning, the cows were turned out of each back yard to hunt for grass and other vegetation to eat during the day. Several people owned horses and pigs, and there were even a few mules. These, along with the cows, roamed at will up and down the streets including the area that might be considered "downtown." Most streets in town were unpaved, although some had a weak covering of gravel and blacktop. In wet weather, one had to try to dodge not only mud puddles but also cowpiles and other "offcasts." In dry weather, it was just the latter.

Because of the roaming livestock, all yards were enclosed by a wooden picket fence. Wooden picket gates had a large barndoor, butterfly hinge mounted horizontally at the top to keep it closed. To open the gate, one would flip one half of the hinge back on the other half. The grass in the yards always seemed to be greener than that outside the fence—to the livestock at least—and many people had some tasty garden vegetables. Thus, as one could expect, if a given gate was not locked by the hinge, or if someone left it open, the householder would more than likely have a yard full of livestock in no time. Occasionally even the hinge "lock" on the gates was not enough to protect the yards from grazing animals. There was one old cow, with only one short crooked horn, that was smarter than 99 percent of all animals in the country. She learned that if she would turn her head sideways she could push her short, little crooked horn under the hinge and flip it over. Then she could pull the gate toward her and thus open it—and walk in. After watching her pull her trick a few times—especially after losing some of our garden to her—we, and many of our neighbors, installed more foolproof locks on the gates.

One night Geneva and I were awakened in the middle of the night by a constant tinkling of a bell. After trying to go back to sleep without success, we realized that somehow we would have to get rid of the noisemaker. Geneva had purchased a sack of potatoes, of good size, the day before so I appropriated three and went out the side door toward the noise. As I did, I suddenly realized that we were in the midst of a pea-soup fog that was so dense one could not make out a shape more than 10 feet away. I carefully headed down the back door steps and toward the tinkling bell. When I reached the yard fence, I let fly with a potato toward what seemed to be the middle of the animal. The potato found its mark and hit with considerable "plop." The slow "ding-ding" immediately turned into a rapid "ding-ding-ding" and two or three horses or mules took off up the street. About this time from across the narrow street in the next yard came "tee-hee-hee" and then "haw-haw-haw." It was the voice of Mr. Arnold, manager of the Crossett Lumber Company. He and Mrs. Arnold had been awakened by the same bell and he was also out in his yard trying to decide what to do about the bell. After a good laugh together, we both went back to bed and let someone up the street worry about what to do about the bell. To this day I have wondered what would have happened if I had missed the mule with the potato and hit Mr. Arnold!

What sidewalks there were in town were wooden, and although these were kept in pretty good repair one always had to watch for a broken or rotten board when walking thereon.

There was only one store in town and this was—you guessed it—the "company stare." It was located on the corner of what is now Highway 82 and Main Street. It was a large rambling wooden building with a second-story mezzanine all around the large main floor. The store had many departments, including groceries, hardware, clothing, and furniture. If one wanted drugs or ice cream, such items could be had by descending two steps into an attached separate room.

All sawmill and woods employees were encouraged to trade at the company "sto." And to help bring this about the workers could draw one week's pay in advance, but this was in the form of coupon books that were good only at this store. The Company owned all the land in town and an area of about 2 square miles surrounding. And, except for the railroad buildings and Western Union, no other private enterprise was allowed. Those who wished to establish a business had to purchase land outside the village limits. It was because of this that North Crossett, West Crossett, and South Crossett came into being. Prices in the stores in these places often were a bit cheaper than in the company store, and those who could resist the temptation of "borrowing" against next week's pay could have cash to trade in the outlying communities.

Because the company owned all houses and other buildings, and would only rent, it could readily determine who would occupy each house. They would rent only to those who worked at the mills or offices, plus the few exceptions like Geneva and me who worked for the Forest Service. Thus, there was no unemployment in town. And very little crime and drinking. If an employee did not produce at his job or caused any trouble, out of town he would go.

Although pay in the sawmill and woods was not large, the cost of rental living quarters was very reasonable. Rates ranged from $5 to $17 per month for most houses. And one could buy a refrigerator or stove on "time" at the company store at a very low rate per month. One could also obtain all the wood he wanted for heating and cooking just for the cutting on company lands.

RESEARCH STUDIES MULTIPLY

Although Geneva and I enjoyed our Crossett living, July 9, 1936, was a big day in our lives. By this date, construction of the big log "Forester's Home" at the Branch Station headquarters, located 7 miles south of town, was far enough along for us to move in (fig. 14). And move in we did, with joy. This was to be our home for the next 33 years, in spite of many attempts to move us back to New Orleans, or to other locations, so that we would have more contact with other scientists and "would not go to seed," as some of the Washington Office staff called it.

Meanwhile, the building program was winding down. Office work on compilation of data from the Pack Selective Cutting Study was expanding, both in Crossett and in New Orleans. Based on data from the Pack study, local cubic-foot and board-foot volume tables were constructed. And I somehow found time to write an article for the Southern Lumberman entitled, "Good Forestry is Good Business." I also wrote one for the Southern Pine Association, titled "Good Lumber From Second-Growth Southern Pine," the first of many articles.

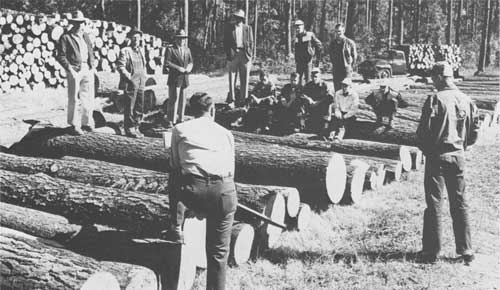

|

| Figure 23. - Part of group of foresters including the Regional Forester and representatives of his staff; the Director of the Southern Forest Experiment Station and representatives of his staff and State and private foresters who attended an annual 2-day meeting at the Crossett Experimental Forest in April 1937. (FS 352513). |

The year 1937 was a banner year on the Crossett Experimental Forest (fig. 23). A 100-percent inventory of all trees by size and species was completed for the 1680 acres. After much thought and planning, we undertook a Method-of-Cutting Study. This was to compare the yields, costs, returns, and the type of stands that would develop from four different methods of cutting in the previously unmanaged second-growth shortleaf-loblolly pine-upland hardwood stands. Three plots, each 2.5 acres in size surrounded by a 2-acre isolation strip, were selected for each of four treatments:

Method 1: This involved clearcutting for sawlogs of all pine and hardwood trees 12 inches d.b.h. and larger, and for pulpwood of all pine trees 6 inches d.b.h. and larger up to sawlog size. Pulpwood was also cut from tops of sawlog trees. Hardwoods that were unmerchantable for sawlogs were either cut into chemicalwood or deadened. Such a method of treating stands was to represent a common type of treatment given the shortleaf-loblolly pine-hardwood stands by many timberland owners in the South.

Method 2: All pine and hardwood trees 12 inches d.b.h. and larger were clearcut for sawlogs. No pine pulpwood or hardwood chemicalwood was cut except from tops of sawlog trees. Unmerchantable hardwoods were deadened or cut into chemicalwood.

Method 3: This was a shelterwood cutting— cutting all merchantable trees except 15-20 per acre of the best quality pines that were 12 inches d.b.h. and larger. Remainder of treatment was same as in Method 1. This treatment was to represent a third step in intensity of treatment for the formerly unmanaged second-growth upland stands.

Method 4: This was a selection cutting—to be repeated on the same areas every 7 years. About 75 percent of the expected cubic-foot growth for 7 years would be removed at the time of each cut. Cut was to be taken from all size classes of trees, with the poorest trees removed first. The aim was to improve both the volume and quality of the growing stock. Unmerchantable hardwoods were treated in the same way as in Method 1. This treatment was to represent one of the most intensive that could be recommended to a timberland owner.

The results were most interesting. The plots clearcut to a 6-inch d.b.h. made an amazing recovery and had an appreciable stocking of pine 6 inches d.b.h. and above in 10 years, together with many hardwood stems.

Over the first 10 years, board-foot volume growth was much the best on the selection plots, but it was also surprisingly good on the treatment #2 plots, (353 bd. ft. per acre per year, Int. 1/4 inch scale). Good board-foot growth, of course, was not expected on the clear cut and shelterwood plots over the years. Pine reproduction was prolific on the shelterwood plots (6,310 stems per acre), and more than adequate on all treatments. The study indicated that where a pine seed source is close to areas of as much as 4.5 acres, and where some treatment is given the hardwoods, timber-growing possibilities on the area are good. At the same time, the more intensive treatments paid off in a big way.