|

HOPEWELL VILLAGE National Historic Site |

|

Washing ore at the Hopewell mines. Practically all

the iron ores mined in the eighteenth century were bog or surface

deposits. Washing the ore freed it of clay or earth.

Courtesy

Chester County Historical Society.

The Technique of Colonial Iron Manufacture

It was natural that men were attracted early to the manufacture of iron in Colonial America, for ore was plentiful. Acrelius, the Swedish pastor at Christina during the middle of the eighteenth century, wrote that there was more ore in Pennsylvania than the people could ever use. Iron deposits were found even among the loose stones on farm lands. The first ores used were those on the surface or just below; little technical knowledge and but a few simple tools were required to mine them. Trenches were dug, rarely more than 40 feet deep. When this depth was reached, new "mine holes" were started. Most of the Hopewell Furnace ores came from the Jones', St. Mary's, and Hopewell Mines, not far from the Village. Only a very few attempts were made at shaft mining before the Revolutionary War. Three or four good miners could generally supply all the ore needed for a single furnace.

Charcoal was the fuel used to smelt iron ore in America throughout the eighteenth century and the first three decades of the nineteenth. It made an ideal furnace fuel, being almost free of sulfur, and its ash, consisting largely of lime and alkalis, supplied part of the necessary flux. The charring was done in open piles, mostly during the winter months. Generally it was done in the woods adjacent to a furnace or forge, but sometimes within the limits of settled boroughs. The charcoal "pit," or "hearth," was simply a circular clearing, dry and level, about 30 to 50 feet in diameter. Workers, known as colliers, were required to "coal" the wood, which was cut into given lengths for this purpose by the woodchoppers and piled in the shape of a cone. As many as 10 or 12 colliers might be needed to keep a furnace going.

Making charcoal. This cross section of a pile of

cordwood illustrates the manner of stacking the wood preparatory to

starting the "coaling" process. The fire is started in the pocket made

by the withdrawal of the center pole.

Frederick Overman,

The Manufacture of Iron in All Its Branches.

When the piles were in process of charring, they had to be watched day and night. Thus the bleak and lonely colliers' huts were built in the silent forests, far from the plantation center where the other ironworkers lived. Hickory was the best wood for making charcoal, but black oak and chestnut, being more abundant, were generally used. The wood was not charred immediately after being cut, but only a short time before it was needed. Large as most of the strong-walled charcoal houses were, they could not hold enough fuel to feed the furnace for any great length of time, and to have left the charcoal outside would have made it unfit for use. An average furnace would consume perhaps 800 bushels of charcoal every 24 hours, and this required about 50 cords of wood of 20- to 25-year growth. Some furnaces consumed almost the yield of an acre of woodland each day. Perhaps the one disadvantage of charcoal as a fuel was its lightness, which made it easy to crush. This was the factor which limited the height of colonial furnaces to a maximum of about 35 feet.

Charcoal wagon at the charcoal house on the

furnace bank. Charcoal was hauled in huge metal-lined wagons from the

"hearths" deep in the forest to the furnace bank where it was

dumped.

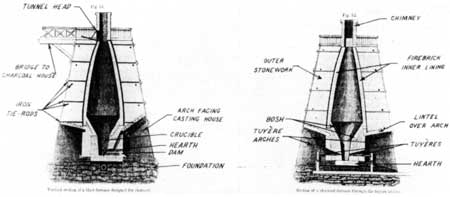

The outside portion of an eighteenth-century furnace stack was usually built of large blocks of limestone or other local stone. Between this and the inwalls came a few heat-insulating layers of clay, coarse mortar, brickbats, and sand. The widest part of the inner chamber, the bosh, was usually 9 feet in diameter, or slightly less. Hopewell Furnace had a bosh of 6-1/2 feet. This bosh, flaring inward and downward, supported the weight of the charge, relieved the central portion from pressure, and thus permitted the free passage of the blast. The crucible, a cylindrical reservoir at the bottom of the furnace into which the molten metal ran down and out over the hearth, was relatively small (only a few feet in diameter) because of the necessity of concentrating the molten iron to prevent it from solidifying.

Cross-section plans of an early blast furnace. in

the Hopewell Furnace the outer stonework is built up in steps or tiers.

There are only one tuyere and two arches.

This illustration

is adapted from one which appears in Frederick Overman, The

Manufacture of Iron in All Its Branches, 1850.

Blast for the furnace or forge in the eighteenth century was supplied by bellows, similar to blacksmith's bellows but much larger, motivated by a huge water wheel. Long before the beginning of the nineteenth century, however, blowing cylinders or tubs, invented in England, were introduced. At first these were crude affairs, hardly more than two casks fitting into one another and moving up and down between four wooden posts. The air, passing first into a leather bag, was piped into the furnace through metal pipes. The blast in both cases was intermittent. They were soon followed by the so-called double cylinders—consisting of cylinders, pistons, connecting rods, together with a third cylinder or box to receive the air—which provided a more constant blast. At Hopewell Furnace the latter type was used at least as early as 1822, and possibly as early as the 1790's. On one side of the furnace was an arched recess, the "tuyere arch," in which a small opening allowed for the insertion of the "tue-iron" (tuyere), and also the iron pipe connected with the receiving box through which the blast was fed.

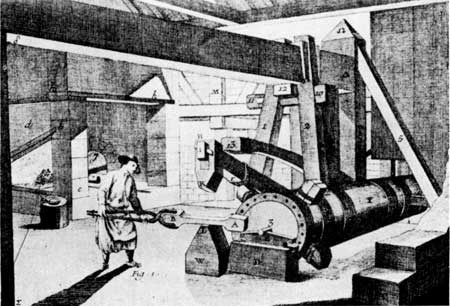

To distinguish between furnace and forge, which were not the same, the blast furnace represented the first step in the production of iron—the reduction of iron ore by smelting into ingots of cast iron or "pig iron." High in carbon content and impurities, and therefore brittle, pig iron was limited in use to such things as stoves and hollow ware. For many products such as nails, horseshoes, tools, and wheel tires, malleable or wrought iron was required. The function of the forge was to change pig iron into this form by reheating in the forge fire and by subjecting the hot, pasty metal to repeated blows of the heavy forge hammer, driving off the excess carbon and impurities. This process was called "refining" and the product "bar iron."

Close-up of Hopewell's last water-wheel and blast

machinery taken about 1925.

The operation of a cold-blast, charcoal furnace was simple, though it required careful management. Iron ore, charcoal, and limestone were carried across the wooden bridge which led from the bank to the tunnel-head, or opening, of the stack, into which they were dumped in alternate layers. At the tuyere the blast was turned in, burning the charcoal at white heat and melting the iron, which then dropped down to the hearth below. The cinder or slag formed by the chemical fusion of the limestone with the impurities in the ore floated on top and was drawn off from time to time. About twice a day, sometimes oftener, the molten iron was run into the casting bed of sand, which was prepared for its reception by molds made from wood patterns. Some imaginative early ironmaster once compared this casting bed to a sow and her litter of suckling pigs. Thus the main stream, or feeder, from the furnace was called the sow, while the side gutters were called pigs. Before the iron became cold, the pigs were separated from the sow and the latter broken up into smaller pieces. It required about 2 tons of ore, 1 to 2 tons of charcoal, and a few shovelfuls of limestone to make 1 ton of pig iron. The average furnace produced some 500 tons of such iron a year.

Only a few workmen were needed to operate the furnace. Two founders, two keepers, two fillers, two guttermen, a potter, and a few laborers included them all. The founder, the most skilled workman at a furnace, regulated the furnace, made the sand molds, and cast the iron. The keeper was the founder's right-hand man and was particularly responsible for the proper functioning of the blast equipment. The filler, as the name implies, "filled" the furnace at the top with the charge from the bridge house. The gutterman had charge of the sand molds in the cast house, while the potter (later called "Moulder"), a highly skilled artisan made the small finished castings.

This was the main process. From the furnaces the pig iron went to refinery and ancony forges, or perhaps to another type of furnace for transformation into blister steel. Rolling, plate, and slitting mills produced wrought iron in bars or rods for use of the blacksmiths. Thus, iron products were manufactured for every need.

Forging an ancony at a refinery forge. The

refinery forge used pig iron from the furnaces. The finished product, an

ancony, was a flat, thick bar of wrought iron, with a knob on each

end.

This illustration is from Diderot and Alembert,

Recueil de Planches sur les Sciences, les Arts Liberaux, et les Arts

Mechaniques, 1765.

|

|

Last Modified: Mon, Dec 2 2002 10:00:00 am PDT |