|

LAKE ROOSEVELT The Grand Coulee Dam and the Columbia Basin Reclamation Project |

|

Section II.

CONSTRUCTION OF THE GRAND COULEE DAM

BRIEF HISTORY OF ORIGIN

The problem of applying the water of the Columbia River to the rich but arid land of central Washington has engaged the interest of settlers and engineers since the days of original settlement. Numerous schemes were conceived, and at least two of them have undergone extensive engineering and economic investigation by State and Federal agencies during the past 30 years. Eleven engineering reports had been made prior to 1933.

In the summer of 1933 preliminary engineering work, financed by a grant of emergency relief funds, was begun under the direction of the Bureau of Reclamation. In November 1933 the building of the Grand Coulee Dam was made a Federal Public Works Administration project (No. 9), and in December the first contract for construction work, the moving of about 3 million yards of overburden, was awarded. The contract far the construction of the base of the dam was let to the Mason-Walsh-Atkinson-Kier Co. by the Secretary of the Interior on July 13, 1934, and on September 25, 1934, the contractor was directed to proceed with the work. Numerous other contracts for railway, highway, grading, building, and other work were let within the year.

|

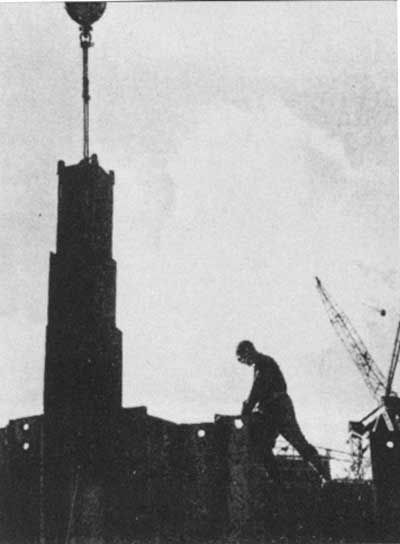

| Rockmen drilled, blasted, and barred down thousands of tons of weathered and loose rock from abutment areas |

AUXILIARY CONSTRUCTION

In order to provide adequate transportation facilities, highways leading to the dam site were regraded, widened, and hard-surfaced by the State; a hard-surfaced road from the Grand Coulee to the dam site was built by the Government; bridges across the river replaced a primitive ferry; and 32 miles of standard gauge railroad from Odair, on the Northern Pacific Railway near Coulee City, to the mouth of the Grand Coulee and into the river canyon were built by the Government, to be operated by the contractor. A 110,000-volt transmission line, 31 miles long, was built from the Washington Water Power Co.'s lines near Coulee City to Mason City by the contractor. Telephone and telegraph lines were built in by the Pacific Telephone and Telegraph Co. and the Western Union Telegraph Co.

|

| Thirty miles of railroad, highway, and transmission line were built up the Grand Coulee to the dam site |

TOWNS AT THE GRAND COULEE DAM

To house the workers at the Grand Coulee Dam two towns were built, one on the west side of the river, Coulee Dam, commonly known as "Engineers' Town," by the Bureau of Reclamation, and one on the east side, Mason City, by the contractor.

Coulee Dam is to be a permanent town for the accommodation of employees on the Columbia Basin Project. It is provided with paved streets, concrete sidewalks, and appropriate water, sewer, and street-lighting systems, and is composed of 77 residences of 6 standard types and sizes, 2 large dormitories, administration building, schoolhouse, post office, garage and shop, fire station, and extensive warehouses and storage yards. To the north of the town site are 4 temporary dormitories and 57 temporary court-type 3-room houses for the use of Bureau employees.

Mason City was designed for only temporary service and is to be dismantled when the dam is finished. Consequently its houses and street improvements are of a less substantial character than those in Coulee Dam; but reliable and efficient water, sewer, and street-lighting systems were installed. There are 3 standard types of small houses, of one, two, or three rooms, with baths and kitchens or ktchenettes, 60 cabin-type dormitories to house 1,360 men, 2 dormitories for women employed in Mason City, a hospital, a hotel, schoolhouses, 2 churches, a laundry, stores, recreation buildings, office buildings, shops, warehouses, and storage yards, and a mess hall capable of seating 1,360 men at one time.

The school system includes a high school and a grade school in which the first three grades are taught. For the succeeding five grades the children of Mason City attend a Government school in Coulee Dam. The younger children from Coulee Dam, and those of high-school age, go to the Mason City schools.

The low rate for electrical energy and the temporary character of the contractor's town are responsible for the use of electricity for house and dormitory heating, as well as for lighting and cooking, in Mason City.

At some distance from the dam site numerous towns have sprung up, and many of the workers on the project live in them. The total population in the vicinity of the dam in 1937 was about 15,000.

|

| Removing from the old channel of the diverted river deep beds of clay deposited during the last Ice Age |

EXCAVATION

One of the major tasks on the project was that of excavation. Under a contract, let in December 1933 for the purpose of providing employment quickly under the emergency relief program, David H. Ryan moved about 2 million yards of overburden, using power shovels, heavy trucks, and large scrapers drawn by caterpillar tractors. Subsequently, the same contractor moved about a million yards of material dislodged in slides on the west side of the river.

The MWAK Co. moved more than 15 million cubic yards of common and mare than 1,300,000 yards of rock by January 1, 1938. Excavation on and adjacent to the dam site will exceed 22 million cubic yards. That at the gravel pit, for the completed dam, will be even greater.

|

| Coulee Dam, the Governments permanent town, and Mason City, the contractor's temporary town, located below the dam site |

CONVEYORS

With the exception of rock, practically all material was transported to spoil banks by the MWAK Co. on belt conveyors. Material, dug by large electric shovels, was hauled by 8-yard to 10-yard trucks and in 12-yard to 20-yard buggies drawn by caterpillar tractors to grizzlies gratelike structures on the ground, where boulders over 13 inches in diameter were pushed off and other material broken up and forced through the grizzlies by bulldozers. Feeders under as many as four grizzlies delivered the material over 60-inch belt conveyors to the surge feeder an the 60-inch main-line conveyor, which carried more than 13 million cubic yards of it a mile away into Rattlesnake Canyon, and dumped it at an elevation of 500 to 600 feet above the point of origin. A part of the material excavated on the east side was carried by belts 4,000 feet across the river and thence into Rattlesnake Canyon. After excavating was completed on the west side, the conveyor system was moved to the east side of the river.

The main-line conveyor was made up in sections, long or short, depending on the grade at any point, each section driven by a 200-horsepower motor. In excess of 5,000 horse power was at one time required to drive the conveyor system. The average daily capacity was 40,000 yards and the maximum daily output 50,839 yards in a 21-hour day. More than a million yards were moved in a month.

|

| Ten and a half million board feet of heavy timbers went into the cofferdam cribs |

COFFERDAMS AND RIVER DIVERSION

A cofferdam is a temporary dam, built for the purpose of excluding water and water-bearing materials from areas in which construction work is to be carried on. Those at this site were constructed by driving interlocking steel piling into the ground to form a water tight fencelike structure, which is protected against collapse by timber framing or cribs, and filling or embankments of sand and gravel.

In constructing a dam, it is necessary to lay bare firm bedrock an which to build the structure, and to divert a stream while the foundation is laid in its bed. In narrow canyons and for smaller rivers, tunnels are sometimes driven around the dam site, and cross-river cofferdams are used to divert the river through them. The topography at the Grand Coulee Dam site and the size of the Columbia River are not suited to such a plan, with the result that several huge cofferdams were built, that on the west side of the river, the largest ever built, being 3,000 feet long parallel to the river. It was built in 90 days.

From the 60-acre area enclosed, about 10 million cubic yards of material were removed, and within it blocks 40 to 8, inclusive, about a third of the dam foundation, were built from the west bank of the river to the abutting rock wall to the westward.

|

| Hundreds of cutters and welders cut off haltered ends of cofferdam sheet steel piles and welded on extensions |

In constructing the west cofferdam, 15,462 tons, 800,000 lineal feet, 151 miles of interlocking steel piles 15 inches wide and in lengths of 40 to 80 feet were driven into the hard clay deposits on bedrock by steam hammers handled by long-boom cranes.

A chain of joined cells, averaging 100 feet in height, approximately cylindrical, and about 50 feet in diameter, filled with sand and gravel formed the west-side cofferdam along the river. Timber cribs with steel—sheet pile facings formed the shore arms.

Block 40, at the river's edge, and block 39 next to it, each 50 feet wide, were built immediately inside the west cofferdam to the height specified in the foundation contract. Blocks 32, 34, 36, and 38, each 50 feet wide, were built up only to a point about 23 feet below normal low-water level, and the alternate blocks 33, 35, and 37 were built only 40 feet higher. These and several other low gaps nearer the west end of the dam base were provided to pass the river water while the middle section of the dam was under construction.

Water was admitted to the diversion channel November 5, 1936. On December 9 the last crib was placed in the downstream cross-river cofferdam, within 30 hours the openings left in it were closed with stop logs, and by December 12 the entire river was flowing through the diversion channel and through the four 50-foot channels over the low blocks 32, 34, 36, and 38.

|

| High water flooded the low east cofferdam in 1935, but the west cofferdam kept a 60-acre working area dry |

|

| The west foundation completed, water was admitted to the diversion channel through it, and construction of the cross-river cofferdams started in 1936 |

The upstream cross-river cofferdam was completed, and unwatering of the 55-acre area enclosed was begun January 3, 1937. In 6 days 80 million gallons of water were pumped out, and on January 9, 2 months ahead of schedule, actual excavation begun.

The construction of the cross-river timber crib cofferdams required 10,500,000 board feet of lumber, enough to build 500 eight-room houses, and the timber cribs on the faces of blocks 39 and 40, 130 feet high, 200 feet long, and 100 feet wide, required 3 million board feet. Timbers 12 by 12 to 16 by 24 inches in cross-section and 40 to 60 feet long were used. Nearly a million cubic yards of gravel were used to fill them. Steel sheet piling used to face the water sides of the cofferdams totaled 2,200 tons.

|

| With the diversion of the river accomplished, the excavation of the river channel and east side were carried out in the summer of 1937 |

THE ICE DAM

Unique in the history of the building of dams was the use here of a temporary frozen earth dam.

Threatened with delay and great expense by a body of more than 200,000 yards of plastic clay which, in spite of timber cribs and concrete barriers, moved toward and repeatedly filled a deep crevice in the bedrock at the east end of the dam, Bureau engineers conceived the idea of freezing the toe of the sloping mass of clay to form a dam across the crevice.

Six miles of pipe, 3 miles of inch and a half pipe inside 3 miles of 3-inch pipe, were driven in an arc between the walls of the crevice. Brine at 0° F. circulated through the pipes, froze a portion of the clay into an arch-type dam, 20 feet thick, 45 feet deep, and with a span of 110 feet.

From August 1936 to April 1937 an 80-fan ice plant kept the ground frozen, and the ice dam held back the clay while excavation of the crevice was completed and the base of the dam built up above the toe of the clay slope.

Movement of the clay, as soon as the ice dam was allowed to thaw out, proved that the expenditure of $35,000 on the ice dam had saved many times its cost, and much valuable time.

| <<< Previous | <<< Contents>>> | Next >>> |

grand_coulee_dam/sec2a.htm

Last Updated: 01-Feb-2008