|

Forests and National Prosperity A Reappraisal of the Forest Situation in the United States |

|

WOOD WASTE

Tightening of the raw-material situation in the timber industries throughout the country and acute shortages in many localities are focusing attention on wood waste. In this report "waste" is used in an intrinsic rather than an economic sense. Wood not used is classed as waste whether or not its utilization is now economically feasible. [24] The urgent need for lumber and the rapidly expanding market for pulp and paper provide powerful incentives for the reduction and use of waste in the woods. Better prices now make it possible to use material that formerly could not be handled at a profit. New uses for wood and improvement of manufacturing processes also open the way for more complete use of our timber. And making use of wood now wasted creates jobs that add to the economic welfare of timber-dependent communities. So it is well to consider the quantity and source of waste; its location and availability; how and to what extent it may be used; and how better use fits into a forest-conservation program.

Quantity, Source, and Location of Waste

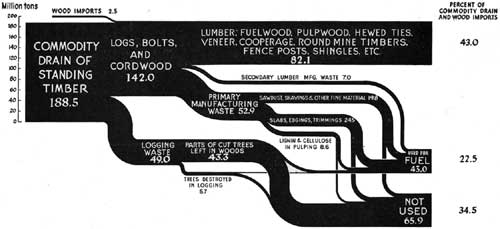

An enormous amount of wood is wasted every year in converting trees into usable products. Only 43 percent by weight of the wood we cut, destroy in logging, or import appears in products other than fuel (fig. 18). Thirty-five percent is not used at all and the remaining 22 percent is used for fuel—often very inefficiently. In 1944, wood waste was estimated at 108.9 million tons (table 22).

|

| FIGURE 18.—Use and waste in logging and manufacturing of all timber products, United States, 1944. (click on image for a PDF version) |

TABLE 22.—Wood waste, United States, 1944

| Nature of waste | Quantity | |

| Million tons1 |

Percent | |

| Logging: | ||

| Parts of cut trees | 43.3 | 40 |

| Trees destroyed | 5.7 | 5 |

| Total | 49.0 | 45 |

| Primary manufacture: | ||

| Slabs, edgings, and other coarse material | 24.5 | 23 |

| Sawdust, shavings, and other fine material | 19.8 | 18 |

| Lignin and other pulping waste | 8.6 | 8 |

| Total | 52.9 | 49 |

| Secondary manufacture of lumber | 7.0 | 6 |

| Total | 108.9 | 100 |

12,000 pounds, oven-dry. | ||

Logging waste accounted for 45 percent of the total, and only 7 percent of it was used for fuel. Most of the logging waste is in cut trees, but other trees destroyed during logging and slash disposal account for 12 percent of the waste in the woods. Some of the logging waste is suitable for lumber, especially in the Douglas-fir subregion.

Primary manufacture accounted for 49 percent of the waste in 1944. Almost half of this is in slabs, edgings, and other coarse material; another three-eighths is sawdust, shavings, and other fine material. The remainder (one-sixth) is fiber, lignin, and other chemical waste in pulp processing. In sharp contrast to the 7 percent of logging waste, 62 percent of the waste in primary manufacture is used for fuel. Some of this is sold for domestic use, but most of it is used in the plants where it originates.

Waste in secondary manufacture of lumber is estimated at 6 percent of the total. All of this is presumed to be used for fuel. Although not included in this analysis, secondary losses of smaller volume occur in remanufacture of other products as, for example, when paper is made into bags and boxes.

Three-fourths of the volume of waste occurring in the form of wood arises in the production of lumber (table 23). Wood waste in pulp and paper making comes next, with about 5-1/2 percent. (If to the waste as wood is added the fiber and chemical waste, the pulp and paper industry accounts for 13 percent of all waste.) Veneer and hewn cross ties each account for a little more than 4 percent of the waste volume, and the remaining 10 percent is divided among other products.

TABLE 23.—Logging and primary manufacturing waste in relation to forest drain by principal timber products, United States, 1944

| Product | Forest drain |

Waste | Proportion of drain | ||

| Used for fuel |

Not used at all |

Product | |||

| Million cu. ft. |

Million cu. ft. |

Percent | Percent | Percent | |

| Lumber | 6,711 | 4,567 | 24 | 44 | 32 |

| Pulp and paper1 | 1,306 | 325 | 8 | 17 | 75 |

| Veneer | 392 | 260 | 30 | 36 | 34 |

| Hewn cross ties | 363 | 254 | 4 | 66 | 30 |

| Fuel wood | 2,203 | 199 | 0 | 9 | 91 |

| Cooperage stock | 174 | 126 | 23 | 49 | 28 |

| Fence posts and round mine timbers | 445 | 47 | 1 | 9 | 90 |

| Shingles | 72 | 45 | 18 | 45 | 37 |

| Other | 516 | 192 | 17 | 20 | 63 |

| All products | 12,182 | 16,015 | 16 | 33 | 51 |

1Includes only waste as wood; excludes waste of fiber and chemical components in pulp and paper manufacture. Does not include waste from processing imported pulpwood, estimated at 9 million cubic feet. | |||||

Manufacture of cooperage stock is the most wasteful of the timber industries: only 28 percent of the volume of the trees cut appears in the product. However, the total volume involved is small. Hewing of cross ties is almost as wasteful and accounts for twice as much waste, very little of which is used for fuel.

About two-thirds of the timber volume is wasted in the production of lumber and veneer. Little more than one-third of the lumber waste but almost half of the veneer waste is used as fuel.

Round products, like mine timbers, fence posts, and fuel wood, involve waste of only 9 or 10 per cent, practically none of which gets used for fuel. In pulpwood operations, however, one-quarter of the wood is lost and, if chemical losses were included, the percent of waste would be about the same as for lumber or veneer.

Only 20 percent of the waste is in the North; 44 percent is in the South and 36 percent in the West (table 24).

TABLE 24.—Logging and primary manufacturing waste by regions, 1944

| Section and region |

Logging waste |

Primary manufacturing waste1 |

Total1 |

| Million cu. ft. |

Million cu. ft. |

Million cu. ft. | |

| North: | |||

| New England | 130 | 103 | 233 |

| Middle Atlantic | 161 | 116 | 277 |

| Lake | 200 | 80 | 280 |

| Central | 293 | 116 | 409 |

| Plains | 4 | 3 | 7 |

| Total | 788 | 418 | 1,206 |

| South: | |||

| South Atlantic | 297 | 393 | 690 |

| Southeast | 557 | 638 | 1,195 |

| West Gulf | 386 | 371 | 757 |

| Total | 1,240 | 1,402 | 2,642 |

| West: | |||

| Pacific Northwest | 927 | 759 | 1,686 |

| California | 127 | 161 | 288 |

| North Rocky Mtn. | 59 | 98 | 157 |

| South Rocky Mtn. | 14 | 32 | 46 |

| Total | 1,127 | 1,050 | 2,177 |

| United States | 3,155 | 2,870 | 6,025 |

1Includes waste from both domestic and imported wood. | |||

In both North and South the waste is widely scattered among thousands of small mills and a still larger number of small logging jobs. In the South the dispersion of logging waste is accentuated by the fact that so much of it arises from the cutting of light, understocked stands. On the other hand, primary manufacturing waste is somewhat more concentrated in the South than in the North because the output per plant averages much greater. The volume of mill waste is 3-1/3 times as great in the South as in the North. Logging waste is much greater than primary manufacturing waste in the North because so much of the cut is from heavy-topped hardwoods.

Contrary to what might be expected, the volume of waste in the West is not as great as in the South, but because of the size of timber and character of the operation it is more concentrated. The greatest concentration is in the Pacific Northwest, where the bulk of the output is from large mills grouped around a few manufacturing centers. Logging waste assumes especially large proportions in the Douglas-fir subregion. Here clear-cutting of heavy stands of virgin timber results in waste averaging 2,500 cubic feet per acre cut. This is by far the greatest accumulation of woods waste suitable for lumber or pulp anywhere in the country.

While the South already has a more diverse industry and makes fuller use of its forest crop than most of the West, it is significant that the proportion of all waste incident to lumbering is almost as great as in the Pacific Northwest. Because of the small size of timber being cut in the South, sawmill waste runs high and this tends to balance the heavy logging waste in the Pacific Northwest:

| Waste as percent of lumbering drain in— | |||

| Logging | Milling | Both | |

| Locality: | |||

| South | 29 | 39 | 68 |

| Pacific Northwest | 37 | 34 | 71 |

Conditions for waste-using industries are favorable in both the South and the West. Both have numerous localities where permanent primary manufacturing plants of substantial size can be sustained. Both need more industries to strengthen the local economy. The South needs new industries to absorb part of the labor force being released by changes in the acreage and technology of cotton production. The West needs them to employ part of a rapidly expanding population without increasing the drain on the resources, and to continue to support people in localities where forest depletion is forcing curtailment of primary timber industries. Because of the volume and concentration of both logging and manufacturing waste, the Pacific Northwest—the Douglas-fir subregion in particular—offers the most favorable opportunity. In the South the largest opportunity for industrial development based on use of wood waste is in the West Gulf region.

Possible Reduction and Use of Waste

It should be apparent from the foregoing discussion of the nature and distribution of waste that economic use of the entire volume disclosed by this study is impossible. There will inevitably be substantial quantities of small size, poor quality, or defective material left in the woods—especially in localities farthest from market and on terrain where logging is most difficult. Furthermore, it is unlikely that we will ever be able to gather up any large part of the waste from some 38,000 small sawmills; and much of the waste from the larger mills—especially those of medium size—will continue to be used to stoke the boilers. But this does not minimize the importance of developing every possible opportunity either to reduce waste or to use it.

Physical recovery.—Part of the waste in logging is simply the result of inefficient practices in felling and bucking. Waste in high stumps and from excessive or inefficient trimming allowance can be reduced by proper supervision or instruction and constant care. The amount of breakage and waste from poor choice of log lengths depends on the skill and judgment of the loggers. Waste from these sources is likely to be more important in farm woodlands and other small operations than on large operations where labor may be more skilled and supervision better.

More of the waste in logging may be recovered by the introduction of equipment especially designed to handle it. Great strides are being made in this direction in the Douglas-fir subregion. Widespread use of trucks and tractors instead of yarding engines and railroad transportation has given greater flexibility to operations and permitted the use of much material formerly left on the ground. The huge volume of material that can not be economically handled by the heavy equipment still needed for logging the virgin timber often may be recovered by working over the area with light equipment either before or after the main logging job.

Portable sawmills are being successfully used to convert waste material on cut-over areas in the Douglas-fir subregion into rough lumber for shipment to finishing plants. Attention is also being given to portable chippers to convert material left in the woods, including that not suitable for lumber, to a form which will permit economic delivery to a pulp mill.

In the hardwood regions also, waste of material that cannot be economically handled in ordinary logging challenges our ingenuity to devise equipment and operating techniques to recover usable material in bolts or other form.

In many localities, integration of pulpwood cutting with lumber operations would help reduce logging waste.

There are similar possibilities for physical recovery of waste in primary manufacture. Inefficient practices, especially in the small mills which now cut so much of our lumber, cause much waste that can be eliminated by technical guidance and assistance. For example, inadequate power, poorly fitted saws, careless edging, and poor piling for seasoning are common causes of waste in small mills.

In the pulp and paper industry there seems to be room for improvement in facilities and practices for storage of pulpwood to reduce losses from decay while awaiting manufacture.

More facilities for manufacturing "small dimension stock" from hardwoods or "cut-up stock" from softwoods might increase the use of short lengths now wasted and permit recovery of more material from slabs and edgings. There are also possibilities of wider use of chips from trimmings, slabs, and edgings from the larger mills for pulp and paper manufacture.

Recent development of processes for shredding or defibrating wood for use in roofing, insulation, etc., has opened large possibilities for recovery of both logging and milling waste. This field of use holds particular interest because bark may be used along with the wood and because almost any species can be taken.

Not to be overlooked are possibilities for wider use of sawdust as filler in plastics and for insulation, wood flour, and other manufactures. The market for sawdust and shavings as bedding for cattle and litter for poultry may also be expanded.

Finally, the possibilities of profitable marketing of wood waste for fuel may be further developed. Briquetting of waste at large mills for domestic fuel has grown to large volume in recent years. The product is being shipped to all parts of the country and is apparently meeting favor with consumers. Wider use of wood waste might result from systematic efforts to increase convenience and reduce costs in the use of hogged waste, whether from mills or woods, for both industrial and domestic fuel.

Chemical recovery.—More dramatic in possibilities and in appeal to the imagination is the recovery of waste by chemical processes. However, the opportunities in this field appear to be limited. Profitable chemical recovery other than the manufacture of pulp and paper usually requires correlation with the lumber or other primary industry in order to keep the cost of raw material down. The prospect of direct recovery of logging waste for chemical manufacture other than pulp and paper is at present small.

In the pulp and paper industry the biggest opportunity lies in recovery of the waste in chemical pulping liquors. Since most of the waste in chemical pulping is lignin, losses may be reduced by modifying the processes so as to leave some of the lignin with the cellulose fiber. Some progress in this direction has been made in recent research.

Processes have also been developed for the manufacture of ethyl alcohol from sulfite pulp waste by fermentation. Widely used in Europe, this kind of recovery is now being applied on a commercial scale by one large plant in western Washington. Further possibilities in this field lie in the production of protein food for cattle (and potentially also for man) by the action of yeast or fungi.

Perhaps the chief opportunity for chemical utilization of sawmill waste lies in new processes of hydrolysis yielding sugar that can be fermented to produce ethyl alcohol, or used for growing of yeast protein. A commercial alcohol plant using wood waste must be so large that there are not many locations where an adequate supply of mill waste could be assured. One such plant has been erected near Eugene, Oreg. Success will depend in part on ability to recover byproducts, particularly those derived from lignin, which is the principal residue and now used only for fuel. Dry ice is a byproduct of the fermentation process.

Other possibilities of chemical recovery may be developed by partial hydrolysis yielding a plastic material that may be used as molding powder or converted into building boards. Furfural; a chemical needed in the plastics industry, may be obtained as a byproduct.

These illustrations of processes that appear ready for commercial application suggest other possibilities that may be developed as knowledge of wood chemistry grows.

Public aid.—The possibilities for waste reduction and use outlined above suggest public action in at least three lines to stimulate progress.

One that can have quick results in all parts of the country is more technical advice and assistance to timber owners and processors. Small owners and operators in particular need help in applying more efficient logging or milling practices that will reduce waste. On-the-ground demonstration, training, and guidance give best results in improvement of technical operations. Marketing assistance to small owners and encouragement of forest cooperatives should help find outlets for material that might otherwise go to waste. Such assistance should also lead to better forest management.

Basic to progress in use of waste is research. Because of the public interest in full use of the timber we cut and because so large a part of our forest problem is with small owners and operators of limited means, the necessary research should be led by the Government. There will, however, always be room and incentive for research by private industry. Most likely to yield results that will lead to immediate reduction of waste is research:

(1) To devise new equipment and new practices for collecting, transporting, and processing logging waste; (2) to facilitate manufacture and use of small dimension, cut-up stock, and other products from mill waste; (3) to enable the pulp and paper industry to use more species of wood; (4) to increase the yield in the chemical pulping processes and otherwise recover waste in pulping waste liquor; (5) to improve processes for wood hydrolysis and partial hydrolysis and find practical means of byproduct recovery.

To get commercial application of research in wood use it is sometimes necessary to go beyond the laboratory stage and undertake demonstrations on a pilot-plant scale. Only a few individuals or timber companies are able to do this on their own resources. There is need for public aid and financing of pilot-plant operations in all phases of wood use involving radical departures from known practices, with attendant risks. This is especially true when large investments in entirely new plants for untried processes are required, as in the case of wood hydrolysis. It is also true for new institutional arrangements involving many people, as in the operation of processing facilities by forest cooperatives.

Other aids.—Beyond public action along the lines indicated above, use of wood waste will be furthered by progress in the integration of wood-using industries and in sustained-yield forest management. These things help provide a favorable environment for industrial application of new or improved practices resulting from research.

Some of our wood waste is due to a traditional pattern of specialized industry. As a general rule our timber has been exploited to provide raw material for one industry or another without regard to future use of material not sought by that industry. Bringing in diversified industries and gearing the composite wood requirements of the industries of any locality to the character and condition of tributary forests means more effective timber use and less waste. This may be accomplished by individual companies diversifying their output, by two or more companies with complementary wood requirements pooling their timber holdings for joint operation or, in a more general way, by over-all planning in a community to achieve and maintain good balance between the timber industries and local timber supply.

Lack of good forest management is another aspect of excessive wood waste. So long as timber was plentiful and cheap there was little incentive for close utilization. But as timber becomes scarce and prices advance, landowners and operators be come increasingly concerned about waste. And when they put their lands under sustained-yield management and become conscious of the costs of replacing productive growing stock, better use for the whole crop may make the difference between success or failure. Thus, while ability to make full use of what is cut improves the opportunity for sustained-yield management, planning for sustained yield is a powerful incentive for the reduction and use of waste.

Relation of Better Use to the Forest Situation

Current information on the waste problem for the country as a whole is so sketchy and so many rapidly changing factors are involved that quantitative estimates of the possible use of material now wasted are very difficult to make and would seem to have little significance. It is worth while, however, to consider the possibilities in general terms in relation to the Nation's needs in forestry.

When all is said and done, the output of sawn products that may come from waste is likely to be only a small percent of the total. Everywhere except in the Douglas-fir subregion, recovery of sawn products from waste will have to be based on such refinements as more care in log making, better practices in small mills, finding practical means of gathering and handling short bolts now left uncut, and expanding the recovery of small-dimension stock from hardwood sawmill waste. Only in the Douglas-fir subregion are there opportunities for new or distinct operations in the recovery of sawn products from logging waste. Even here recovery is likely to be confined to a few favorable localities where large concentrations of usable waste are easily accessible.

Somewhat better opportunity exists to augment the pulpwood supply by use of material now wasted. This can be achieved by better integration with lumber logging and sawmills and by relogging. As in the case of sawn products, the Douglas-fir subregion has the greatest concentration of both logging and milling waste that may be used for pulp. But because there are only a few pulp mills in the Pacific Northwest and because most of them are located on navigable water, distance from the mills limits recovery of logging waste for pulp manufacture even more than for lumber. Many of the logging operations where waste is now accumulating are too far from the pulp mills to permit salvage for this purpose.

Notwithstanding a growing use of building board made from specially treated wood fiber, new uses based on chemical processes seem more likely to broaden the field of wood use than to replace staple products such as lumber, plywood, and pulp.

In the aggregate, then, use of material now wasted is not likely to result in a decisive reduction of the pressure on our forest growing stock. In the main, our output of staple forest products will continue to be met by direct drain upon the forest, and this demand is not likely to be greatly reduced by new uses for wood waste. Conversely, it seems probable that should the output of new products that do replace lumber and pulp rise to a level that would significantly affect the pattern of over-all consumption, it would become necessary to supplement recoverable waste by drawing directly upon the forest itself.

In any event the long-range growth goals discussed earlier in this report would not be much affected by what may be accomplished in use of waste. This is so not only because of the considerations outlined above, but also because the volume of usable waste will be much less when the virgin timber is gone. More will be scattered and more will be in small pieces, economically difficult to handle. Less will be suitable for sawn products.

The benefits to be gained in use of waste, therefore, lie only partly in helping to bridge the gap between present output and potential requirements. Even more important is the contribution that new uses can make to national welfare in other ways. New uses serve to expand employment per unit of forest growth. This is needed to support people and strengthen the regional economy where timber is a major resource and the primary timber industries are declining. Thus the use of waste can serve to help cushion the economic shock of forest depletion. It has special significance for the South, where added employment would help offset the decrease in manpower needed for growing and handling the cotton crop.

At the same time the use of waste should add incentive for better forestry. Use of waste removes or reduces fire hazard on cut-over areas and it implies a broader and better opportunity to improve forest growing stock by using inferior species and less desirable trees. Unfortunately the effect is often in the opposite direction: the opportunity for added income through closer utilization may lead to premature cutting and liquidation of needed growing stock. However, as previously stated, ability to utilize material now wasted may spell the difference between success and failure in planning sustained-yield operations.

Thus, entirely aside from making a direct contribution to the Nation's immediate need for timber products, better use of the timber we cut can have an important bearing on our progress in the widespread application of sustained-yield management that will be needed to achieve desirable growth goals. A good market for all kinds of forest-grown material is the key to intensive forestry, and use of waste should be a major objective in a comprehensive program of forestry for the Nation.

| <<< Previous | <<< Contents>>> | Next >>> |

|

misc-668/sec9.htm Last Updated: 17-Mar-2010 |