|

Trails of the Past: Historical Overview of the Flathead National Forest, Montana, 1800-1960 |

|

TIMBER HARVESTING

Introduction

For many years the U. S. lumber industry was migratory. Centered in the Northeast and upper Midwest until the 1890s, the industry next moved to the Southeast and then to the West Coast. The Rocky Mountain states were the last to develop. The shortage of good white pine in the Great Lakes states led the logging industry to relocate to the West. The construction of railroad lines, plus increased mining, agriculture, and fruit-growing in the West all helped create a demand for and a way to market timber (Bolle 1966:14; Hudson et al. ca. 1981:184).

The lumber industry was active in the Flathead Valley on a small scale beginning in the 1880s, increasing greatly when the Great Northern Railway reached the valley. Timber trespasses - the stealing of timber from the public domain - were common in the 1890s in the accessible wooded valleys of the Flathead. Although there was generally a large number of sawmills in the Flathead, a handful of the largest companies tended to dominate the market, notably the Somers Lumber Company (1901-1948). One of the main timber products of Flathead County were railroad crossties, generally cut from Douglas-fir or western larch and either hewn in the woods or milled in portable or permanent sawmills.

Flathead National Forest timber sales were infrequent and small-scale until after World War II (the major exception was the 1913-19 sale of almost 90 million board feet in the Swan Valley to the Somers Lumber Company). Logging on national forests around the country increased dramatically in the 1940s and 1950s, and the Flathead National Forest was no exception.

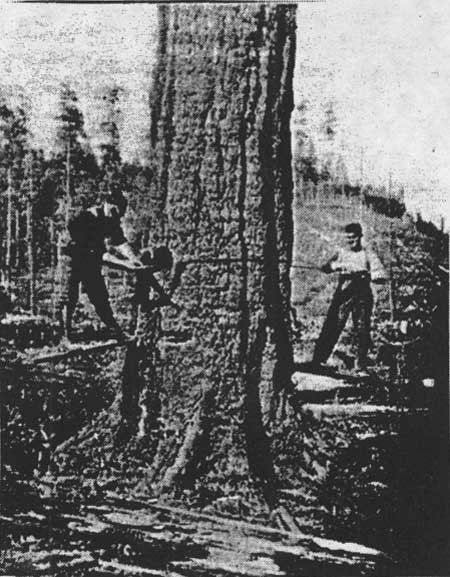

Until the 1930s, most logging in the Flathead was done by men who lived in the woods in logging camps. Horses, logging railroads, and river drives were used to transport logs in the early years, later supplemented or replaced with tractors and trucks. Similarly, the two-man crosscut saws gave way to chainsaws. There were a number of labor strikes among woodworkers and sawmill workers in the Flathead Valley in the early years. The most notable of these strikes were organized by the I. W. W. (the Wobblies).

Over the decades, the timber industry in northwestern Montana has changed dramatically. The locations of sales have shifted to less accessible areas, the species harvested have changed, harvesting methods have been mechanized, the number and size of mills have varied, and contract logging has replaced company crews.

Although there was generally not much logging on the Flathead National Forest until the 1950s, evidence of earlier sales can be found. Good examples are the logging railroad grade and remains of logging camps in the Swan Valley, which were built by the Somers Lumber Company in the 1910s. High stumps with springboard notches carved in them in the more accessible parts of the Forest evoke the era of the crosscut saw.

1800s to 1905

In the 1860s eastern Montana had more logging activity than western Montana. There were, however, a number of early mills in the Missoula area and in the Bitterroot Valley, mostly associated with gold camps. In the 1870s and early 1880s many small mills failed. They recovered within five years, though, due to large-scale quartz hardrock mining replacing smaller placer operations and the construction of railroads through the area (the Utah Northern came to Butte in 1881 and the NPRR crossed Montana in 1883) (Moon 1991:4-5).

By 1884, mills west of the Divide were supplying the Anaconda Copper Mining Company (ACM) with 300,000 cords of wood a year for smelter fuel alone. In the mid-1880s, the ACM's Anaconda mine was the most productive copper mine in the United States, and the company was influential for decades in state politics and media. In 1888, the ACM was using 4,000 board feet of timber a day in its mines. Once the importance of timber to mining was recognized, mining corporations formed their own sawmilling operations. For example, the ACM bought the Big Blackfoot Milling Company to stabilize its lumber supply (Moon 1991:5; Toole 1968:353; Schutza 1975:54).

Railroad construction and maintenance created a tremendous demand for lumber. In the early 1900s the nation's railroads consumed about 1/5 of the timber harvest. Railroads needed over 2,500 crossties per mile to support their tracks. They also needed timber for bridges, pilings, telegraph poles, snow fences, fuelwood for the camps, cribbing, tunnel timbers, fuel, corduroy roads, and railroad buildings. Many small sawmills sprang up along railroad routes. By the late 1800s, huge permanent and also portable mills were operating 24 hours a day all over northwestern Montana to meet the demand (Olson 1971:4; Moon 1991:5).

In the Flathead Valley, the construction of the Great Northern Railway led to a great deal of logging along the line. In 1891, while the railroad was being built across the Divide, portable saw mills were set up at McCarthysville and at the junction of Summit Creek and the Middle Fork to saw Douglas-fir timbers for bridges. Several million feet of dimension timber were used for bridges and tunnels. The benchlands along the line were cut over, some extensively. The construction crew cleared the line for the tracks, using that timber for ties, and then cut the remaining ties needed from nearby stands of timber. Several hundred thousand hewed ties were used. In the Summit and Bear Creek areas, over 100 buildings were constructed for the grading camps. In building the tote road paralleling the line, the path had to be cleared and 122 bridges and several corduroy roads were made (Inter Lake 13 March 1891; Ayres "Flathead" 1900:312, 315-16; Green 1969:I, 16; Ayres "Lewis & Clarke" 1900:47).

The coming of the Great Northern to the Flathead Valley encouraged the conversion of small mills to larger steam plants using circular saws. The first large mills in the area were built when the railroad came through. The Great Northern did not receive a government land grant in Montana, but it did purchase enough timber land in the Flathead to make it one of the largest landowners in the valley. Montana lumbermen had a difficult time competing effectively with eastern lumber until the GNRR arrived and introduced lower freight rates (Bolle 1959:63-64, 68; Burlingame 1957:11, 6).

One of the first sawmills in western Montana was built in 1856 by the Jesuits at St. Ignatius. Foy's Mill was one of the earliest mills in the upper Flathead. The water-powered mill was built in 1884 and had a capacity of 10,000 board feet a day. Another relatively small early mill was the Jessup mill located on the east side of the valley. Other sawmills were built in the late 1880s and early 1890s. The largest mill in the valley for many years was that built by the John O'Brien Lumber Company, which began operating in 1901. Many small mills near the Great Northern line produced only railroad timbers (Schutza 1975:28-29, 31, 55; McDonald 1936:5).

The early mills generally depended on water for power and for transporting the logs to the mills, but this shifted as steam-powered mills and railroad lines were established.

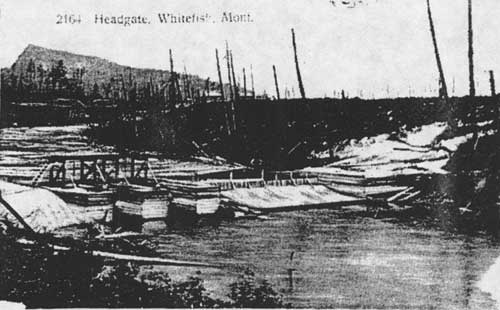

Whitefish Lake was logged in the late 1880s. The Baker Brothers Company built a mill at the outlet of the lake to saw lumber that was floated down the lake or hauled by sled across the ice. This mill was later sold to the John O'Brien Lumber Company, and the Somers Lumber Company operated the business until 1918 (see Figure 78) (Schafer 1973:2, 13-14).

|

| Figure 78. Sawmill on Whitefish Lake (courtesy of Stumptown Historical Society, Whitefish). |

The early small mills of the 1880s in the Flathead Valley had very little effect on the "vast forests" of the valley. In the late 1880s, much timber was available free to the small mills as many settlers were glad to have it taken off their land. Some homesteaders even girdled the trees on their land and left them to die standing (Johns 1943:IX, 157; Flathead County Superintendent 1956:22).

Lumber was the first product exported from the Flathead Valley after the railroad was completed in 1891. The ACM's Butte & Montana Company (BM) mill was built at the mouth of the Stillwater and Whitefish Rivers east of Kalispell in the early 1890s; its main purpose was to produce lumber and fuel for the mines and smelters in Silverbow County. It sawed and planed lumber floated in on the Stillwater, then sold it for shipment on the railroad to the east. Flathead timber was also shipped by railroad to Great Falls to supply fuel for the smelter there. The Flathead operations were competitive with Missoula mills because the GNRR kept its rates the same as the NPRR. The BM also exported lumber to eastern Montana and to North Dakota for sale. In 1904 the GNRR increased its freight rate, and the BM could no longer compete for the Butte market; the ACM sold it at a loss (see Figure 79) (Butcher 1967:73-74; O'Neil 1955:70, 82).

|

| Figure 79. Butte & Montana Commercial Company mill yard, ca. 1895 (Great Northern Railway Country 1895). |

One of the early logging sales on land that later was included in the Flathead Forest Reserve took place the winter of 1890-1891. George Chilson, a former buffalo hunter, ran a logging camp on Logging Creek (on the east side of the North Fork of the Flathead River). As many as 30 men were paid $50 a month to work on the sale. Under contract with the Columbia Falls Mill Company, they cut several hundred thousand board feet of ponderosa pine, but Chilson ran out of money by February. Some of the logs were decked along Logging Creek but never driven down the river to a mill; others rotted on skids in the woods (Ayres "Flathead" 1900:283; Vaught Papers, 1/UV; Vaught ca. 1943:385-389).

After the financial panic of 1893 and the accompanying low agricultural prices, the economy of the Flathead improved. There was such a great demand for lumber and for labor in logging and sawmilling that residents sent a delegate East to recruit laborers, and several thousand reportedly came as a result. At that time a train load of lumber left the area daily. In 1898, according to a national survey, Montana had only 24 stationary sawmills, 3 portable sawmills, and 11 shingle mills. At that time there was only one logging railroad in the state (Mauritson 1954:5D; Fernow 1899:119).

In approximately 1899 the prices for lumber were still low. Some of the "best timber" - ponderosa pine - within two miles of Columbia Falls sold for $1 per thousand board feet on the stump; it sold from the mill for $7. By 1908, however, rough lumber was worth $11-12 per thousand board feet (Ayres "Flathead" 1900:258; Elwood 1980: 158).

By 1900 the mines and the railroads dominated Montana's timber industry. Beginning in 1900 a timber boom hit the state. The first big sale of public-land timber was from the Bitterroot National Forest ca. 1910. In general there was a low demand for national forest timber because the more accessible bottomlands were privately owned and because the larch and Douglas-fir on the higher land (such as on national forests) were not considered desirable species. The market at the time was for white pine and ponderosa pine (Bolle 1966:17).

Timber Trespasses

When Montana Territory became a state in 1889, federal grants of land from the public domain were given to the state to sell or use in support of schools, usually sections 16 and 36 of each township. Granville Stuart came to the Flathead in the summer of 1890 to select the lands granted to the state. At that time, the Flathead Valley, which he described as having few natural meadows, was being cleared of its timber and the cutover lands converted to agricultural use (1 August 1891, vol. 2, RS 29, MHS). Much of the land had already been conveyed to settlers, railroads, and so on, so the state had to choose lieu lands instead of sections 16 and 36 where appropriate. Granville Stuart recommended that the state survey timbered sections that had not yet been too heavily settled. In the process, he reported on the state-related timber trespass activities going on in the Flathead Valley at that time.

For example, Stuart reported on a steam mill cutting western larch, ponderosa pine, and Douglas-fir on a school section by men who "well knew it was school land." Stuart estimated they had cut between 2 and 2.5 million board feet of logs on the section. He continued, "It is high time the cupidity and reckless disregard of law of these timber thieves received a check." He mentioned that a man representing the Butte & Montana Commercial Company, which had a sawmill in the area, was requesting a permit to cut 80 square miles of selected state land around Whitefish Lake. Stuart commented, "Verily these sawmill men have their gall with them all the time." He recommended they should be limited to cutting only two sections (1,280 acres) at any one time (24 July 1891, vol. 2, RS 29, MHS).

Stuart also recorded many examples of farmers who were leasing State land and cutting timber on the State sections which they then hauled to sawmills and sold. He commented that the people were mostly poor and were struggling to make ends meet but felt that efforts should be made to stop the trespasses (May 1897, vol. 1, RS 29, MHS). As historian John Ise said, "fraud was a frontier way of life" (quoted in Steen 1976:25).

Much of the land in the Flathead Valley was turned over to private ownership through the Timber and Stone Act of 1878. Sometimes the claimants were fairly obvious about their fraudulent intentions. For example, seven members of the Eckelberry family filed on separate tracts of land north of Ashley Lake in the early 1900s. James Eckelberry stated that he did not have an interest in a sawmill, but that he bought the timber as an investment. He patented 320 acres of land in 1906 and the next month sold the land to C. I. O'Neil, owner of a lumber company in Kalispell. Those acres are now owned by Stoltze Land and Lumber Company. At the same time, Eckelberry was purchasing outright many hundreds of acres in the area and selling them to lumber companies. In that same section, Louretta and Emma Eckelberry each patented 160 acres in 1912, sold the land the same year to the Conrad National Bank, and the land later passed to the American Timber Company. This half-section is now once again national forest land (FNF Class; Flathead County plat records).

In 1908 three Flathead Valley lumber companies (J. Neils Lumber, Somers Lumber Company, and the Northwestern Lumber Company) were brought before a hearing for using "dummies" in securing title to timber claims. Somers and Northwestern were asked to return to the state certain lands for which they had negotiated (Schutza 1975:67; Morrow n.d.:37).

The government generally won timber depredation cases in the lower courts and lost on appeal; it was more successful in prosecuting small individual trespassers who could not afford to hire well-paid lawyers to appeal the cases to higher courts. According to historian K. Ross Toole, "timber depredation in Montana is more typical than extraordinary." In total, nearly 64,000 acres of Montana forest land passed into private ownership through the Timber and Stone Act (Toole 1968:360; Butcher 1967:110; Schutza 1975:67-68).

One of the major timber trespass cases in the Flathead Valley involved the ACM-owned Butte & Montana Commercial Company. In December of 1890 the BM started building a dam at the outlet of Whitefish Lake to have enough water to drive logs to a sawmill in the area of what later became Kalispell. The dam raised the level of the lake by 8'. The company purchased forested land in the Whitefish Lake area, and in the fall of 1891 it contracted with Taylor & Fogg for logs. The loggers cut only the good timber and skidded it to the lake, and the larch lumber was sold in Great Falls. The next year the federal government brought action against the company for timber trespass. In the spring of 1894 a special agent came to the area, and settlers estimated the company had cut a little over 6 million board feet from the public domain rather than land they owned. The case was dropped, however, when the company declared bankruptcy (Schafer 1973:12-13; Whitefish Pilot 20 October 1960; O'Neil n.d.; Schutza 1975:67).

Logging on Private Lands, 1905-1942

By 1914 the two largest landholders in Montana were the NPRR and the ACM, and they earned revenue from the land by their logging operations. In approximately 1900 the ACM began to buy large tracts of timberland from the NPRR and from private holders. Eventually it owned more than 1.1 million acres. In 1905 the ACM bought the Montana Improvement Company (including its land and resources) and converted it into the lumber division of the ACM. Over the next ten years the ACM cut nearly half of the timber cut in Montana (Morrow n.d.:32-33; Baker et al. 1993:43).

In 1917 the Somers Lumber Company owned 60,000 acres and the Northern Pacific Railroad owned 140,000 acres in Flathead and Lincoln Counties. In fact, only four owners controlled 51% of the private holdings ("General Summary of Timber Situation," 2400 - Timber - Historical - General Corr, RO:4-5, 13).

The ACM had permits to cut free timber for its mines in Butte for many years, but the company also used these permits to cut timber for retail sale of lumber throughout the state. The ACM was operating in Columbia Falls under the name of Daly & Co. by 1897. In 1898 it was the ACM, Lumber Dept., of Columbia Falls, and soon the business went under the name of the Big Blackfoot Milling Company, the timber subsidiary of the ACM. The ACM bought enormous tracts in northwestern Montana in the 1890s as a timber source for the Butte mines; in 1910 the Big Blackfoot Milling Company owned over 176,000 acres of land in Flathead County. The ACM purchase of timber at Seeley Lake in 1905 was the first stumpage sale that the Forest Service made to that company (Kerlee 1962:37; box 5, folder 5, MC 169, MHS; box 51, folder 18, MC 169, MHS; Bolle 1966:15; Coon 1926:105; Sanders County Ledger, 25 March 1910:2).

In approximately 1909 there were 30 sawmills tributary to Kalispell, with an annual cut of 150 million board feet of lumber (see Figure 80). At that time the lumber mills were shipping about 3,500 railroad cars of lumber per year (see Figure 81). Most of the companies, like ACM, owned large tracts of timbered land along rivers that could be used for driving logs to the mills (Great Northern Railway, ca. 1909:21).

|

| Figure 80. Interior of State Lumber Company sawmill, LaSalle, 1898 (courtesy of the Mansfield Library, University of Montana, Missoula). |

| Mill Name | Mill Location | Daily Capacity (BF) | Number of Men Employed |

| Northwestern Lumber Co. | Kalispell | 70,000 | 100 |

| Boorman Lumber Co. | 35,000 | 40 | |

| Enterprise Lumber Co. | 35,000 | 40 | |

| Kalispell Lumber Co. | Athens | 45,000 | 30 |

| Kalispell Lumber Co. planing mill | Kalispell | - - - | 55 |

| T. B. Farrow (2 mills) | Marion | 35,000 | 50 |

| W. F. Kelsey | Marion | 20,000 | 25 |

| McMannamy | 30,000 | 25 | |

| John O'Brien Lumber Co. | Somers | 240,000 | 300 |

| GNRR tie preserving plant | Somers | - - - | 75 |

| Jessup Doe Milling Co. (3 mills) | Montford | 70,000 | 105 |

| John O'Brien Lumber Co. | Whitefish | 75,000 | 50 |

| Hutchison Lumber Mill | Whitefish | 35,000 | 30 |

| lath mill | east of Whitefish | 30,000 lath | |

| Gussenhoven | Fortine | 25,000 | 35 |

| Eureka Lumber Co. | Eureka | 40,000 | 60 |

| State Lumber Co. | Columbia Falls | 500,000 | 65 |

| Hunt Tripet Lumber Co. | Columbia Falls | 30,000 | 40 |

| John Olson Lumber Co. | Columbia Falls | 35,000 | 30 |

| Parker Zorzie Lumber Co. | Columbia Falls | 180,000 | 30 |

| A. O. Westberg | Columbia Falls | 25,000 | 20 |

| Figure 81. list of some of the sawmills in Flathead County in 1907, with daily capacity and number of employees ("Montana Beautiful" 1907:65, 69, 71). |

Much of the timbered land around the Stillwater River was logged in the early years because the river was drivable. A large block of private timber land that was harvested along the Stillwater River was later acquired by the Forest Service. The Northwestern Lumber Company mill outside of Kalispell sawed timber from the Stillwater until its mill burned in 1911. In 1916 the Somers Lumber Company bought all of its holdings (millsite, flowage, and almost 15,000 acres of timber on the upper Stillwater River). Another large mill during this period was the State Lumber Company, located on the Whitefish River northwest of the airport (in 1923 the mill was moved to Half Moon) (Taylor 1986; Elwood 1980:156, 158).

The Somers Lumber Company often had several large sales going at one time. For example, in 1912 the company contracted with Henry Good to harvest 35 million board feet of logs over the next two years on the Stillwater River, mostly on land owned by Good. This job employed about 300 men and 50 teams in a line of camps ("Somers Lumber Company" 1912.1).

The Empire Lumber Company bought up timber claims and homesteads in the Truman Creek drainage near Kila. One of the logging camps had a narrow-gauge railroad, the tracks following Wild Bill and Emmons Creeks. The company used V-shaped log chutes and a flume. When the mill closed, the equipment was moved to the mill at Half Moon (Elwood 1980:162).

Montana lumber mills have survived many cycles of economic depression and revival. From 1913 until 1915 Montana mills generally operated at less than half their capacity. In 1914, less than 50% of the lumber manufactured in Montana was used or marketed within the state. The main market outside Montana was in the prairie states west of the Mississippi River (Schutza 1975:55; Moon 1991:54).

In 1921, due to an agricultural depression, higher freight rates, and a glutted market, 38% of all the mills in Montana closed, but the post-war building boom led to the return of small mills. The peak of logging in northwestern Montana before World War II came in 1925, declining until 1927 and then rising again until 1929. Beginning in 1932 production in northwestern Montana began to rise, although nationally the timber industry remained low until World War II (Burlingame 1957:11, 8-9; Sundborg 1945: 14; Steen 1976:197).

Some timber harvested in Canada was milled in the United States. In approximately 1925 a semi-portable sawmill was set up in the Akamina Pass area just north of the international boundary, and some wood products were shipped east of Waterton Lake. The mill supplied timbers to the oil companies in the area for derrick construction in the early 1930s. There was also some logging in the North Fork north of the boundary with access to mills in the United States to the south. Poor transportation facilities and low market demands for small timber restricted logging activity north of the border until the 1960s, when timber was harvested extensively in response to the spruce bark beetle epidemic. The policy of sustained-yield management did not come into use on Crown-owned lands in British Columbia until the 1950s (Ringstad 1976:6; Fregren 1960:12).

The market for various species of trees changed over the years; this greatly affected which areas in the Flathead Valley were logged during which decades. Western white pine was for many years the most desirable species in the northern Rockies, but it was not well represented on the Flathead (see Figure 82). In 1926, ponderosa pine represented about 33% of the total cut in Montana. Western larch and Douglas-fir represented about 50% combined, and lodgepole pine over 10%. At that time, 64% was cut from private lands, 19% from state forests, and only 17% from national forests. Sixty per cent of Montana's timber was on national forest land, but it was less accessible than the private land, and only 11% of the timber was ponderosa pine. As one observer commented in the 1920s, "the cream is being skimmed at this time." He recommended developing markets for the less desirable species such as larch and lodgepole. Ponderosa pine was the mainstay of the large mill operators in the Flathead Valley, while railroad ties were the mainstay of the small mill operators. As the supply of ponderosa pine declined, the mills had to rely on a mixed species product (Cunningham 1926:21, 54, 58; Ibenthal 1952:52a).

| Scientific Name | Common Name | Composition (%) | Elevation Range |

| Pinus monticola | White pine | 3.5-11.0 | 3000-5000 |

| Pinus ponderosa | Ponderosa pine | 2.0 | 3000-4000 |

| Pinus contorta var. latifolia | Lodgepole pine | 1.0-14.0 | 3000-6500 |

| Pinus albicaulis | Whitebark pine | 0.5-1.0 | 4000-7000 |

| Larix occidentalis | Western larch | 35.0-50.0 | 3000-5000 |

| Larix lyallii | Subalpine | — | 5000 |

| Picea engelmannii | Engelmann spruce | 20.0-23.0 | 3000-6000 |

| Tsuga heterophylla | Western hemlock | 1.0 | 3100- |

| Pseudotsuga menziesii var. glauca | Douglas-fir | 11.0-17.0 | 3000-6000 |

| Abies grandis | Grand fir | 1.0 | 3000 |

| Abies lasiocarpa | Subalpine fir | 1.0 | 3000-7000 |

| Thuja plicata | Western red cedar | 17.0 | 3000-5500 |

| Juniperus scopulorum | Rocky Mountain juniper | — | 3000 |

| Juniperus communis | Common juniper | — | 3000-6500 |

| Taxus brevifolia | Pacific yew | — | 3000-6000 |

| Figure 82. Timber types in the Flathead River drainage, 1922. White spruce (Picea glauca) was not listed in the 1922 chart (Kirkwood 1922:85). |

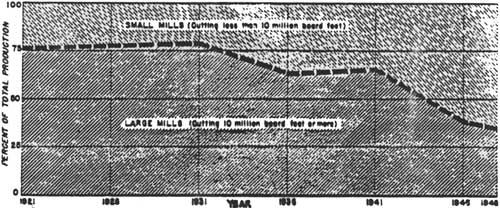

During the Depression the demand for timber plummeted, and many mills shut down. Demand rose slowly in the late 1930s. The Somers Lumber Company continued to decline, marking a shift away from a virtual monopoly towards the leadership of several independent mills. Small mills continued to produce rough lumber for local use, and medium mills expanded somewhat because of the availability of public land. Montana sawmill production did not reach pre-Depression levels, however, until 1942 (see Figure 83) (Bolle 1966:18; Morrow n.d.:64).

|

| Figure 83. Production of small mills relative to large mills in Montana, 1921-1948 (Kemp 1950:6). |

Planed and kiln-dried finished lumber began to replace rough lumber as a Flathead export product in the 1930s. The demand for Douglas-fir and western larch products was rising. According to a 1934 report, the main forest products in western Montana were saw logs for lumber, railroad cross ties (western larch, Douglas-fir and ponderosa pine), poles (cedar), piling (Douglas-fir and western larch), mine timbers (western larch, Douglas-fir, and ponderosa pine), cordwood, local farm timbers, and pulpwood (white fir, Engelmann spruce, and western hemlock). Unemployed men often cut cordwood, bringing it in to sell at a designated area on Kalispell's west side known as Wood or Market Street (Bolle 1959:70-71; Brown 1934:217; Swan River Homemakers Club 1993:69; H. Elwood 1994).

Some mill owners found their own markets for "undesirable" tree species. For example, B. J. Boorman built a sawmill in 1899 west of Kalispell in a stand of western larch. He found a new and profitable market for this "unmarketable" timber in New York City, where it was used for finishing lumber. John O'Brien of the O'Brien Lumber Company promoted the use of larch for molding and siding. He used it in the interior of his own home and boasted that "Flathead larch is the best larch in the west" (Johns 1943:IX, 13; 1905 article in Flathead County Supt 1956:96).

Sawed mine timbers were used in the early years, but by the early 1950s round timbers were more in use because they were cheaper. In approximately 1916 the copper market of World War I created such a high demand for mine timbers that local suppliers could not provide enough, so some of the companies entered the larch/Douglas-fir forests for timber. ACM, for example, harvested most of its round timbers in western Montana (Hutchison 1952:31-32).

The needs of the building industry also affected area logging. Kalispell logging contractor George Slack returned from World War I to a building boom, and because the least available item was wood lath, he immediately began manufacturing lath (used in buildings for plaster-and-lath walls and for snow fences). Until then lath had been cut from slabs and waste material at the large mills. Slack set up two dedicated lath mills, one at Coram and one where Martin City now is (that mill later moved to Lake Five) (Green 1971:III, 128-129).

One of the companies that continued to produce lumber during the Depression was the J. Neils Lumber Company. Julius Neils founded the J. Neils Lumber Company in 1899 in Cass Lake, Minnesota. In 1906 the company began purchasing timber lands in Flathead County, buying even-numbered sections among the odd-numbered NPRR land-grant sections that were held largely by the ACM. They hoped to consolidate their holdings later by land exchanges with the ACM. Because of a rumor that a railroad line was going to be built up the east side of Flathead Lake, J. Neils purchased a mill site on Flathead Lake, but it was never used for that purpose. In 1914 the company bought the Dawson Lumber Company in Libby, moved there, and began to consolidate their timber holdings (P. Neils 1971:17, 25; Burlingame 1957:11, 9; Moon 1991:21).

By 1915 J. Neils' holdings in the Flathead included 12,640 acres in the Columbia Falls area and 22,496 acres east of Flathead Lake. According to George Neils, the company owned about 150,000 acres in the Flathead area, mostly on the North Fork, the main fork of the Flathead, and east of Kalispell. The company sawed its last lumber at Minnesota in 1923; this led its managers to try to manage the timberlands in their western operations so as to have permanent operations and stable communities (P. Neils 1971:28, 40; G. Neils 1976:10).

In the 1930s J. Neils got the contracts to log the white pine around Echo Lake (most local mills were not familiar with logging or marketing white pine). In 1935 a Forest Service inspector reported that the company was delivering 5 million board feet of white pine in 32' logs on trucks to the railroad. He commented that "the company is making an honest effort to get the most out of the timber," and that the white pine on the Flathead should all be salvaged immediately because the Forest was not included in the proposed blister rust control plans (G. Neils 1976: 14; Elers Koch, 26 August 1935, Flathead Inspection Reports Region One, RG 95, FRC).

The northwestern Montana Christmas tree industry was a product of the Depression and a welcome source of cash (see Figure 84). The trees in the area held their needles better than those in other parts of the country. During the Depression, 12% of the Christmas trees used in the United States came from Flathead or Lincoln County. In the early 1930s the first sale of Christmas trees on Forest Service land in the area took place on the Blackfeet National Forest. By 1954 Flathead County was producing about a million trees, mainly Douglas-fir. Some was grown on national forests; harvesting the trees was felt to improve the composition of the forest. In 1955, however, the amount of Christmas trees harvested on national forest land in the Flathead was negligible (just over 3% from federal land in 1955) (Cusick 1986:61; 31 March 1933, Flathead Inspection Reports Region One, RG 95, FRC; Montana Conservation Council 1954:51-52; "Area Lumber Output" 1956:4).

| Year | Number of Trees | |

| 1936 | 1,242,500 | |

| 1937 | 1,534,500 | |

| 1938 | 1,676,000 | |

| 1939 | 1,967,350 | |

| 1940 | 2,338,350 | |

| 1941 | 3,082,650 | |

| 1942 | 2,203,750 | |

| 1943 | 3,102,480 | |

| 1944 | 2,755,750 | |

| 1945 | 2,723,500 | |

| 1946 | 3,299,400 | |

| 1947 | 2,515,640 | |

| 1948 | 3,098,886 | |

| 1949 | 3,256,956 |

| Figure 84. Annual production of Christmas trees in Montana, 1936-1949 (Kemp 1950:32). |

The shifting centers of the lumber industry from the Lake states to the South to the Pacific Coast led to concern about a timber famine, the fear that there was no new area (except Alaska) to which the industry could move. Professional foresters and citizens alike called for regulation of logging practices and the application of sound management practices on public and private lands (Cox 1985:191, 193-194).

During the 1910s and 1920s the country moved away from the government regulations common to the previous years and focussed instead on developing a cooperative approach between public and private sectors. With the Depression, government regulations returned and federal programs increased in importance. The Weeks Law of 1911 marked the beginning of extensive cooperation among federal, state, and private industry to protect the timber in the country's forests (Cox 1985:193-194).

The Weeks Law encouraged state participation by providing matching funds if a state set up a system to protect the forested watersheds of navigable streams. Under a general land administration act of 1909, a Montana state forestry board was created to manage the state forests on forestry principles, to encourage private owners to preserve and grow timber, and to conserve forest tracts on watersheds of the streams of the state. The Clarke-McNary Law of 1924 provided for federal-state cooperation in a variety of activities, including production and distribution of forest planting stock, cooperation in farm forestry education, and the federal purchase of lands necessary for the production of timber (Cox 1985:194; Kinney 1917:69; Winters 1950:16).

The Copeland Report, written under the authority of the Forest Service and completed in 1933, provided a blueprint for reorganizing the forestry practices of federal, state, and private owners. It also represented a rededication of the Forest Service to the principles of conservation and public welfare promoted by Gifford Pinchot. The report stressed public ownership of forest land and cooperation with private forest owners in managing private lands. Among other things, the Copeland Report addressed the modern concept of multiple use (Gates 1948:598; Steen 1976:202).

During the 1930s the concept of sustained yield changed to the need to coordinate public and private timber supplies to create a stable market. Article X of the National Recovery Act was mandatory for just one year (1934-35), but it was subsequently maintained voluntarily by industry and the Forest Service as a guide for good forest management. The Lumber Code was intended to revive the industry by reducing production quotas and requiring higher wages and a shorter work week. Article X prescribed sustained yield, a comprehensive fire prevention program, protection of young growth, and replanting after logging (Baker et al. 1993:123, 144-145).

Railroad Ties

Cutting railroad ties was a big business in the Flathead for decades, with the preferred species being Douglas-fir and western larch. Railroads used an average of 2,640 crossties per mile, with a varying rate of replacement. Between 1894 and 1898, after the completion of the Great Northern Railway line, 10,000 railroad ties and 1,000 telegraph poles were reportedly cut along the GNRR line in the Flathead area (Olson 1971:12; 1905 claim, 1905 Trespass Book, FNF CR).

Lumberman John O'Brien contracted with the railroad in 1901 to build a sawmill at the head of Flathead Lake with an annual capacity of 40 million board feet of lumber; he agreed to saw and deliver to the tie-treating plant 600,000 ties each sawing season for 20 years (see Figure 85). In return, the railroad built a spur track to the sawmill and agreed to loan the money and to place a certain amount of orders. The original tie plant was built in 1901 and was replaced by a new plant in 1927. The mill took in ties from Flathead logging operations, treated them, and then shipped them out as needed along the GNRR line. In 1906 John O'Brien sold his interest in the company to the GNRR, which became the sole owner, and in 1907 the name was changed to the Somers Lumber Company after the town (Somers was named for a Great Northern agent who looked out for the railroad company's interests in connection with the lumber company). Somers was a company town. In 1937 the mill employed 250-375 people, and it owned 122 dwellings that it rented to employees, providing the water and electricity. Many of the workers were immigrants from Italy, Germany, and Norway. The company also had retail yards in North Dakota, in Havre and Conrad, Montana, and ran a sawmill on Whitefish Lake from 1906-13 and a retail yard there until 1928 ("Corporate History" n.d.:1-3, 10; Elwood 1976:6-7).

|

| Figure 85. Original Somers sawmill, built 1901 (courtesy of Henry Elwood). |

By the winter of 1904-05 the O'Brien mill was manufacturing 60 million board feet of lumber, half of which were made into railroad ties and treated with creosote. The operation included a sawmill, planing mill, box factory, and a sash and door plant, and the mill could manufacture about 5,000 triangular ties a day (1905 article in Flathead County Superintendent 1956:95-96).

The railroad tried to save money and lumber by making the ties last longer. Between 1900 and 1915 the wood preserving industry grew dramatically, and the proportion of ties treated increased from less than 5% to about 30% of all ties. During this period the railroads switched from using zinc chloride to creosote as the preservative. Railroad ties treated after 1910 probably had an average life of 15-20 years. The average use of ties by all railroads began declining about 1908 (Olson 1971:44, 104, 122).

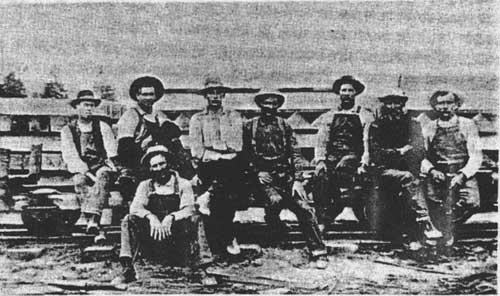

James J. Hill brought the idea of "self-tamping" three-cornered ties to the United States from Germany. Triangular ties had a 12" face and were 8" deep. These ties were sawed in the Somers mill and were used on the Great Northern line until the early 1920s (see Figure 86) (1905 article in Flathead County Superintendent 1956:95-96; Elwood 1976:24; Elwood 1994). The triangular ties were replaced by four-sided, rectangular ties.

|

| Figure 86. Somers Lumber Company workers sitting in front of triangular railroad ties (courtesy of Henry Elwood). |

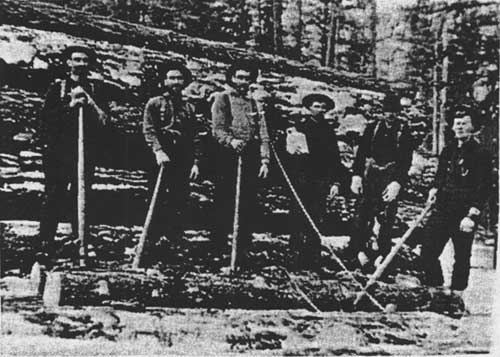

"Tie hacks," the men who worked in the woods hewing cross ties, included many homesteaders who hewed ties for cash income. Often they lived in the woods during the week, returning home only on weekends. After falling the tree, the sawyer would cut the tree into 8' or 8-1/2' sections, depending on the desired length of the tie. An 11" diameter section would make one tie. A 24" diameter section would yield four ties. Teams of sawyers would follow the strip blazed by the cruisers. Some sawyers would work alone in order to earn more money (they were paid per tie). In order to be able to handle the two-man crosscut saw without a partner, the sawyer would use a makeshift tool called a "rubber man." He would drive a rod into the ground opposite his position by the tree and then would secure a "rubber band" made from an inner tube to the rod and to one end of the saw. The "rubber man" would pull the saw from one side, less efficient than another sawyer but workable. Tie hacks would then stand on the log and hew two sides, then peel the bark off the two sides that had not been hewed. A good tie hack could reportedly hew 20-25 cross ties a day (24FH466, FNF CR; Green 1969:I, 15-16; Swan River Homemakers Club 1993:54; Downes 1994).

Most of the railroad tie cutting in the Flathead was done on private land; the Forest Service often turned down tie sales. In 1907 Edward Dickey applied to cut 40,000 ties from an area near the railroad at Paola. The sale area was on gentle terrain, close to the railroad, and had good timber. The local administrators favored the sale, but the Washington Office rejected it because Dickey would be letting the larger trees stand (the large trees were not harvested for hewed railroad ties). In 1917, however, with the increased demand due to World War I, the tie timber was harvested, and in 1944 the larger trees were sold to a lumber company (Shaw 1967:123).

Railroad ties became a big item of production in Montana sawmills in the mid-1920s (see Figure 87). Most ties cut before then were hewn by tie hacks. In 1925 about 900,000 hewn ties were being cut annually, a little more than 40% of the total tie output. By 1931 hewn ties composed only about 1% of the total; all the rest came from sawmills. The shift to sawed ties brought a concentration of tie production to Flathead, Lake, Lincoln and Sanders counties, which had concentration yards, preservation plants, and good stands of larch and Douglas-fir, the preferred species for railroad ties in the West. Many railroad lines tried Douglas-fir and other species in order to avoid crosshauling railroad timber (Hutchison 1952:30; Olson 1971:124).

| Year | No. of sawed railroad ties | |

| 1925 | 1,225,000 | |

| 1926 | 1,054,796 | |

| 1927 | 959,175 | |

| 1928 | 915,895 | |

| 1929 | 824,515 | |

| 1930 | 613,143 | |

| 1931 | 670,000 | |

| 1932 | 525,000 | |

| 1933 | - - - | |

| 1934 | - - - | |

| 1935 | - - - | |

| 1936 | - - - | |

| 1937 | - - - | |

| 1938 | 554,540 | |

| 1939 | - - - | |

| 1940 | 1,237,668 | |

| 1941 | 1,398,968 | |

| 1942 | 2,319,978 | |

| 1943 | 2,239,584 | |

| 1944 | 2,090,428 | |

| 1945 | 1,302,238 | |

| 1946 | 1,008,619 | |

| 1947 | 1,336,555 |

| Figure 87. Annual production of sawed cross ties in Montana, 1925-1947 (Kemp 1950:32). |

Hewed railroad ties contained more wood; but sawed ties saved freight, had a more uniform absorption rate during pressure treating (making the treatment more effective), and were uniform bearing. They also produced marketable by-products - tie siding - instead of waste chips. The transition to sawing integrated tie production into the large lumber markets. The selection of trees for harvesting also changed. Hewed ties used only 11-15" diameter trees, but sawed ties used all sizes of trees (Olson 1971:112-113).

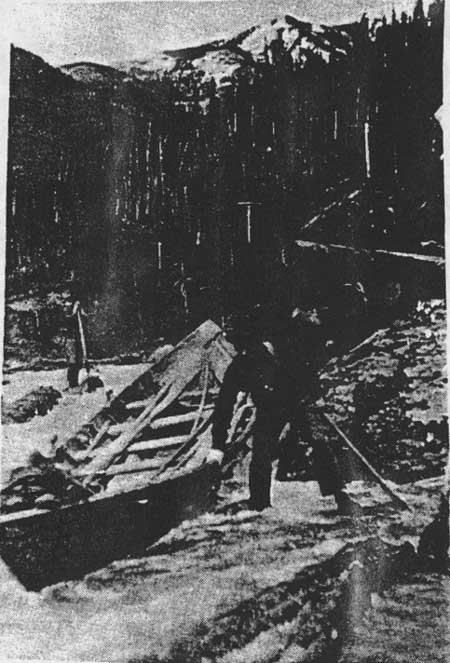

The next innovation in railroad tie logging was the development of portable tie mills located at the logging sites. After a December 1924 windstorm north of Columbia Falls, a portable mill was set up at the site to salvage the down timber for ties. In 1929 McMillan & Kerr bought a section of timber from Somers Lumber Company and cut the Douglas-fir and western larch into railroad ties with a portable mill (see Figure 88). They delivered the ties and a few sawlogs by truck to the Somers mill at the going price. This contract marked the real beginning of the switch to the use of portable mills in the woods (see Figure 89). By 1932 the success of the method had been proven; that was the last year the Somers sawmill produced cross ties. After that, it produced only a relatively small number of switch ties. When portable mills were used, all side cuts and waste materials (anything less than 6" in diameter) were left in the woods, which saved on transportation costs but wasted a great deal of wood. Woodsworkers later worked over and resawed the slab piles ("Corporate History" n.d.:6-7; Mansfield 1986).

|

| Figure 88. McMillan & Kerr tie mill in Patrick gulch near Kalispell, on Flathead National Forest, 1930 (photo by I. V. Anderson) (courtesy of USDA Forest Service, Region One, Missoula). |

|

| Figure 89. Hauling railroad ties by truck, Eureka, 1929 (courtesy of the Mansfield Library, University of Montana, Missoula). |

Flathead logger Clarence Saurey remembered the effect of the stock market crash of October 1929 on the portable tie mills in the Flathead, which were salvaging timber burned in the Half Moon fire of 1929:

Everything was a-running, you know, you could hear them sawmills a-singin' all over the woods. And it shut down overnight...Next morning there wasn't a thing running at all (Saurey 1983).

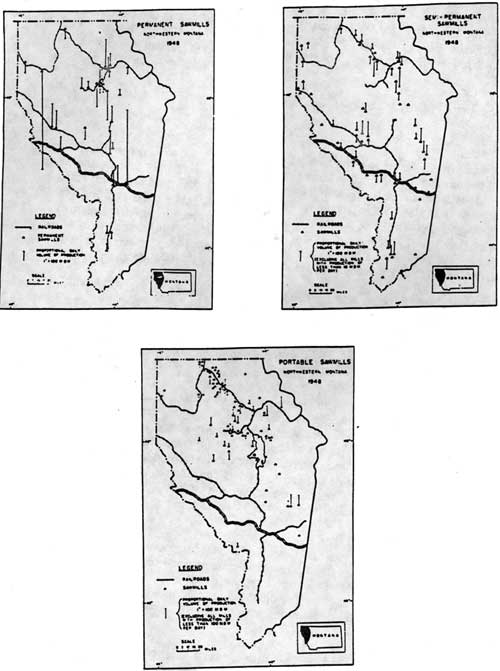

The change to sawed ties greatly increased the number of small portable circular mills in the Flathead; their number peaked at the height of tie cutting during World War II (see Figure 90). In the Kalispell Working Circle at that time, about 100 circular mills were in operation, plus three band mills. By the late 1950s, however, the market for ties was reduced because of improved preservative treatment and the reconstruction of railroad roadbeds (Ibenthal 1952:48->49).

|

| Figure 90. Location and relative production of permanent, semi-permanent, and portable sawmills in northwest Montana, 1948 (from Helburn 1950). (click on image for a PDF version) |

Ties treated at Somers were shipped as far as Minnesota on the Great Northern line. The record production at the tie plant was in 1944. The previous year, almost 1-1/2 million ties had been sawed at 36 small mills in the county and treated at the Somers plant. By the 1950s many railroads had reorganized their distribution systems to eliminate some of their treating plants. Other technological changes helped increase the life of ties, such as increasing their length from 8' to 8-1/2' or 9' (Elwood 1976:34; Olson 1971:165, 167). The demand for railroad ties, therefore, declined significantly.

The main companies cutting railroad ties in the Flathead were Somers Lumber Company, the Kinshellas, and the Olson Brothers. Some tie contractors had quite a large business in the Flathead. For example, in 1912 George Slack had a contract with the Great Northern to deliver hewn ties, and in the first year he delivered to the right-of-way 700,000 ties. In 1931 the Kinshella brothers and their father signed a 7-year contract to cut railroad ties and sawlogs on Somers Lumber Company land from Lupfer north. The 150 men at the camp received approximately 13 cents per tie (a little more for the larger ones). Workers earned $2 a day and were charged 90 cents a day board. The ties and logs went to the Somers sawmill and tie-treating plant (24FH466, FNF CR; "Personal Experience Record of Capt. George W. Slack," SC 126, MHS; "Large Logging Project" 1931; Cusick 1986:61).

Many railroad ties were cut in the late 1930s and through World War II in the Pleasant Valley area, which had literally dozens of portable tie mill sites. The Forest Service did not issue permits for mill sites on the national forest, but sometimes sales on private land trespassed onto national forest land (24FH154, FNF CR).

In the late 1940s, western larch and Douglas-fir railroad ties accounted for almost 20% of the total sawmill output of Montana. Small portable mills, with 6-8 men on their crews, were typical. They cut 2,500-12,000 ties a setting and moved rapidly from one tract to another. For each 1000 board feet of ties sawn, they could cut nearly 250 board feet of lumber. When prices for larch and fir boards were low, the tie siding went into the slab pile (Hutchison 1952:31).

Forest Service Logging, 1905-1942

General

Until World War II, timber sales on the Flathead National Forest were generally small scale. Most of the timber was harvested in those years from private lands, not federal lands, near rivers or in accessible areas. The main exceptions were sales designed to harvest scarce species, such as a sale of white pine on the lower North Fork and a cedar sale on Good Creek in the Stillwater area. In 1908, no national forest in Region One had an estimated timber harvest of more than 1% of the total amount of standing timber. Commercial sales of national forest timber did not exceed a billion board feet annually until 1924, but even then it still represented only 1% of the national timber market (Baker et al. 1993:65; Clary 1986:40).

In 1905, Forest Service policy held that the timber on the national forests was supplemental to, not competing with, private holdings, and that the timber should be harvested to meet local needs only. In 1907 early Forest Service timber sales peaked, but these sales represented only 2% of the 44 billion board feet total. Pinchot later claimed that the national forests existed for public welfare purposes, to stabilize local industry and to encourage development (Steen 1976:90-91).

The first administrative manual for the forest reserves was issued in 1902 by the Department of Interior. The section on timber began with regulations on the free use of timber. For sales, local demand had preference. After a potential purchaser requested a timber sale, the government would inspect it, mark the trees or area to be cut, and then advertise the sale to the public for bids. The Forest Service believed strongly in its mission to promote the wise use of forest resources. In a 1907 handbook, the Forest Service stated clearly, "The timber is there to be used, now and in the future...National Forests are made, first of all, for the lasting benefit of the real home builder. They make it impossible for the land to be skinned" (Steen 1976:59; Pinchot 1907:11, 17).

The first manual provided no appraisal formulas, but timber prices at that time were seldom over $2 per thousand board feet (the first appraisal manual was issued in 1914). Before 1910 the reproductive capacity of a forest was essentially a matter of guesswork. Then the Forest Service adopted allowable cutting levels in order to protect against over-cutting. The allowable cut represented the amount that would produce sustained-yield harvests (Wiener 1982:2; Clary 1986:30, 34).

In the early years, the Forest Service issued free-use permits for cutting timber. Settlers, miners, residents, and prospectors could harvest $100 worth of timber annually from forest reserves each year, provided it was used for domestic purposes, firewood, fencing, buildings, or mining. For example, in 1906 on the Lewis & Clark Forest Reserve one man was granted 10 cords of dead standing and down lodgepole near the junction of Upper Twin Creek and the South Fork to build a cabin in the vicinity. In 1905 the forest reserve issued 131 free-use permits that granted about 34,000 board feet and 215 cords of green wood, plus 71,000 board feet and 1,500 cords of dead wood (Wiener 1982:3; "Free Use of Timber, 1905" FNF CR).

Up to 1907 most of the timber harvested on the Flathead National Forest was on land that is now in Glacier National Park, mostly fuelwood and timber for building homes in the Lake McDonald area. The early timber sales on the Forest, few in number, were usually for $1 per thousand board feet, 3 cents for 30-foot poles, and 15 cents per cord for fuel wood. When the Park was designated in 1910, logging for revenue continued to be allowed within the Park. In 1911, the Park ordered a sawmill and shingle machine, and superintendent Logan stated "the cutting of fully matured timber will not in the least mar the beauty of the park, but will benefit the growing timber...Numerous inquiries for lumber have been received, and in a short time it is believed lumber will rank first among the sources of revenue" (Shaw 1967:1, 12; Logan 1911: 10).

The 1910 fires killed 5-10 billion board feet of mature timber in Idaho and western Montana and led to a glut of timber on the market in Montana. Salvage sales were offered, but only 1 billion board feet were actually sold and cut. The Forest Service even approved the cancellation of current contracts to allow firekilled timber to be used instead (Wiener 1982:33).

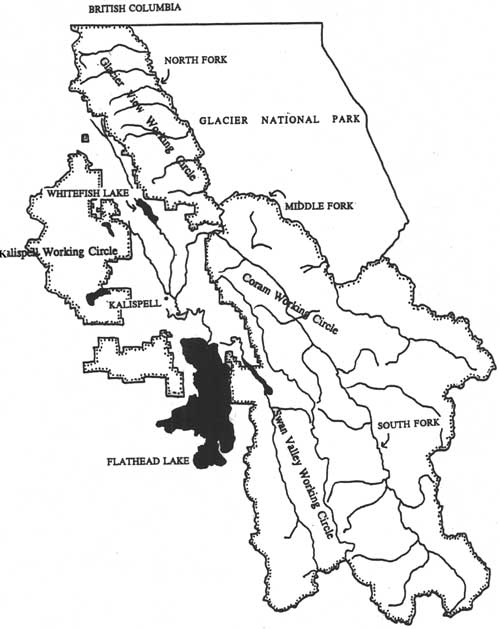

By 1923 each national forest had been divided into "working circles" to aid in timber management planning. The boundaries of these divisions were based on topography, transportation networks, management objectives, stand composition and condition, ownership, and the area needed to support local forest-based industries. The boundaries were reviewed and modified as needed. The allowable cuts were determined within that area, consistent with sustained yield over the working circle. Timber management plans were prepared on 10-year cycles (see Figure 91) (Preston 1923:582-585; G. Robinson 1975:62).

|

| Figure 91. Boundaries of the working circles on the Flathead National Forest, ca. 1960. (click on image for a PDF version) |

The 1920 Flathead National Forest timber management plan called for a sustained yield on each of the working circles to encourage established industries to continue on a permanent basis. It noted that private timber would be "dumped on the market as rapidly as possible" and that federal and state timber provided the only reservoir of timber for future use (see Figure 92) (FNF, "Preliminary Statement of Policy," 20 November 1920, box 85429, item 2, RG 95, FRC).

| Species | Blackfeet National Forest | Flathead National Forest |

| western white pine | 74 | 260 |

| ponderosa pine | 102 | 270 |

| lodgepole pine | 151 | 379 |

| Douglas-fir | 483 | 1120 |

| western larch | 1113 | 1500 |

| Engelmann spruce | 1079 | 769 |

| white and alpine fir | 81 | 321 |

| limber and whitebark pine | 4 | 34 |

| cedar | 3 | 85 |

| hemlock | — | 12 |

| total saw & tie timber | 3090 | 4750 |

| cedar poles | 12000 | 35000 |

| Figure 92. 1924 estimates of timber on the Blackfeet and Flathead National Forests. Figures are in million board feet ("Forest Statistics for Region One, approximately 1925," RO). |

In the fiscal year ending June 30, 1916, the Flathead and Blackfeet National Forests combined sold 46.5 million board feet of timber, and the sawmills in the same area and same period cut 191.0 million board feet. The percentage of the cut coming from the national forests was fairly significant at that time, and at least one local lumberman complained that the government, by putting the timber on the market, was depressing an already overloaded stumpage market. One of the reasons timber was logged more on private lands in the early years was because of the more stringent regulations on Forest Service sales, such as requirements to leave a 16" stump, dispose of brush, and so on (Charles I. O'Neil to H. H. Chapman, 9 February 1917, 2400 - Timber - Historical - Genl Corr, RO; Hannon 1970).

In 1917 there were complaints in the Kalispell area that the Forest Service was selling its timber at too low a rate ($1.25 per thousand board feet) to the Eureka Lumber Company, thus reducing the stumpage value of all private timber land holdings in the area. Forest Service competition, it was feared, would prevent private profits. Senator Myers, in response, introduced legislation that would prohibit the sale of any national forest timber for less than $3 per thousand. This conflict was apparently resolved by a consolidation of private land ownership, as in 1920 a Flathead National Forest report stated that the complaints had largely been silenced by "the absorption of a large part of the small holdings by larger owners who contemplate early exploitation" (Semi-annual report to the Forester, 1 May 1917, 1380 Reports - District 1, 1917; "Public Sentiment," 18 November 1913, in 1380 Reports - Historical - Public Sentiment, RO; FNF, "Preliminary Statement of Policy," 20 November 1920, box 85429, item 2, RG 95, FRC).

According to a contemporary Forest Service report, people were complaining about national forest stumpage prices because they speculated on timber lands and thought the value would go up, but they had actually paid too much for the land in the first place. If the federal government were to put a high price on the stumpage, then the opportunities of the small operator would be eliminated ("General Summary of Timber Situation," 2400 - Timber - Historical - General Corr, RO:4-5, 13). During the late 1920s, prices for Flathead and Blackfeet National Forest timber sales rarely were higher than $2 per thousand board feet (see Figure 93).

| Buyer | Date | MBF | Timber type | Price/MBF | Total Sale |

| L. R. Smith | 2,000 | white pine | 2.00 | 4,000.00 | |

| F. Calkins | 3/10/26 | 72 | larch & fir | 2.17 | 156.24 |

| J. Oxender | 5/18/26 | 970 | larch & fir | 1.75 | 1,697.50 |

| Nyack T&T | 1/8/27 | 1,931 | larch & fir | 2.14 | 4,132.34 |

| Nyack T&T | 1/8/27 | 1,677 | spruce | 2.14 | 3,588.78 |

| H. Good | 4/25/27 | 200 | larch & fir | 1.50 | 300.00 |

| Johnson & Ramlow | 12/21/27 | 250 | larch & fir | 1.65 | 412.50 |

| Julius Berg | 8/4/27 | 55 | larch & fir | 1.50 | 82.50 |

| Johnson & Ramlow | 1/28/28 | 1,012 | larch & fir | 1.70 | 1,720.40 |

| Julius Berg | 8/11/28 | 80 | larch & fir | 1.50 | 120.00 |

| Julius Berg | 1/16/29 | 200 | larch & fir | 1.50 | 300.00 |

| Julius Berg | 1/15/29 | 20 | larch & fir | 1.50 | 30.00 |

| 11 tie sales | 8,467 | larch & fir | 1.94 | 16,540.26 |

| Figure 93. All timber sales on Flathead and Blackfeet National Forests, May 1926-January 1929 ("Appraisal" 1930:11). |

World War I had a significant effect on the demand for lumber and on Forest Service resources. At the start of the war in 1914, foreign purchase orders were canceled, but then demand increased greatly because the Allies lacked the manpower to harvest timber in Europe. Under the War Powers Act, the Forest Service was permitted to sell timber without competition, and price ceilings were imposed. During World War I the U. S. Army required a great deal of lumber in Europe. Instead of shipping it overseas, the Army organized a regiment of experienced foresters and lumbermen, many of them Forest Service employees, to be stationed in Europe. In France, the regiment cut about 300 million board feet of lumber plus poles and firewood, operating about 90 sawmills. More than 30,000 American foresters, woodsmen, and mill men served in Europe, many returning home with a new respect for the conservation methods practiced in France and for the frustration with government controls felt by industry in the U. S. The war strengthened industrial trade associations and increased industry-wide cooperation necessary to allow the lumber industry to deal with the government on more equal terms (Cox 1985:205; Wiener 1982:112; Clary 1986:68-69).

Region One of the Forest Service helped out in the 1919 fuel emergency by allowing officials to obtain wood from the national forests for the use of those in need under free-use permits. The consumer paid only the actual cost of cutting and delivery (16 December 1919, 2400 Timber - Historical - General Corr, RO).

Commercial sales on the national forests remained low during the interwar period. In 1921, for example, the Flathead National Forest sold only 8 million board feet of timber in commercial sales ("Timber Sales Business" 1921:6-7).

In approximately 1929, the Flathead National Forest was still making "no effort...to push the sale of national forest timber. It is considered better management of public resources to preserve and protect this timber until such time as the private timber has been cut and a new source of supply is needed to perpetuate existing industries and meet the demand for forest products." At that time only about 10% of the annual production of 75 million board feet of lumber in the Flathead Valley came from the Flathead National Forest (USDA FS "Flathead National Forest" ca. 1929).

In 1931, during the Depression, President Hoover restricted national forest timber sales because of overproduction. The Forest Service prohibited timber sales over $500 except to supply mills dependent on the national forests, to supply domestic paper mills, or to salvage damaged timber (W. Robbins 1982:143).

As the prices for paper products rose, the Forest Service fielded inquiries about the possibilities of a pulp industry in Region One. The Forest Service considered the Engelmann spruce stands on the Flathead and Blackfeet National Forests as the most accessible timber of the kind desired by the Wisconsin pulp mills. The Blackfeet National Forest, under the supervision of supervisor Robert McLaughlin, did an extensive study in the late 1910s of the pulpwood resources of northern Montana, hoping to encourage the establishment of a paper industry there ("Robert P. McLaughlin" 1929:4; Silcox to the Forester, 10 May 1917, 2 Semi-annual Report, 1380 Reports - Historical - District 1, RO).

The Forest Service study focussed on Big Creek, Deep Creek, and Canyon Creek in the North Fork. The report indicated that 75% of the timber in that area was good for pulpwood, with a reserve supply to the north and south. It recommended a pulp and paper mill on or near Flathead Lake, with the fluming of logs down tributary streams to the North Fork. The report also stated that the Forest Service would establish new stands after harvest, as it was practicing forestry on the basis of sustained yield. In the 1930s Forest Service officials in the area were still recommending a pulp or paper operation in the Flathead that would be supported by 95 million board feet of spruce and subalpine fir annually. The controlling factor, they believed, would be developing a market for the associated western larch and Douglas-fir ("Possibilities" ca. 1920:3-6, 11-12; Ibenthal 1936:14).

Some flathead timber was shipped out of the area for pulp, although the proposed pulp mill was not built. In 1927 subalpine fir and spruce were being shipped in the log from Nyack to a Spokane pulp mill because the Somers Lumber Company would not accept the logs (Wilfred W. White memos, 11 & 15 August 1927, Flathead Inspection Reports, Region One, RG 95, FRC).

Montana's first pulp mill was built in the Missoula area in 1956 (Bolle 1964:11). Pulp and plywood mills helped stabilize the income of lumber mills. The industry, traditionally cyclic, was affected by ups and downs in the building industry and by fluctuations in the demand for and price of lumber.

Swan Valley

The public land in the Swan Valley was recognized early as an excellent "logging chance." At the turn of the century, when no commercial timber harvesting had yet been done in the Swan, H. B. Ayres recommended using an electric railway to log the Swan Valley, with a sawmill located at the mouth of the Swan River. In 1906, a Forest Service inspector commented that the Swan and the South Fork both offered excellent opportunities for the construction of roads to make large bodies of timber available for harvest (Ayres "Lewis & Clarke" 1900:79; 28 November 1906, entry 7, box 4, "Reports of the Section of Inspection," RG 95, NA).

The first large (and still the largest ever) timber sale on the Flathead National Forest took place in 1913, when the Forest sold timber in the Swan Valley to the Somers Lumber Company. The sale led to the first railroad logging on the Flathead National Forest (most railroad logging was done on private holdings). The 1913 and 1917 sales represented a total cut of 87 million board feet of sawlogs and 302,000 board feet of railroad ties. The logging took place between October 1914 and July 1919 (Shaw 1967:1, 123-124; J. C. Urquhart to Regional Forester, 4 February 1937, FNF Lands; Wiener 1982:35).

The Somers Lumber Company sale in the Swan Valley was located on over 9,000 acres in the Swan River drainage on the east side and at the head of Swan Lake. The Forest Service intended to list much of the land for settlement as soon as the timber had been removed, as it was considered of high agricultural value. The timber in the 1913 sale consisted of about 51% western larch, 25% Douglas-fir, 12% Engelmann spruce, 10% western white pine, and 2% red cedar. The company paid $2 per thousand board feet, regardless of species, which the Forest Service considered a good price ("100,000,000 Feet," 1913:418; F. A. Silcox to Thomas Cooper, 23 January 1917, entry 70, box 7, RG 95, NA; Wiener 1982:35).

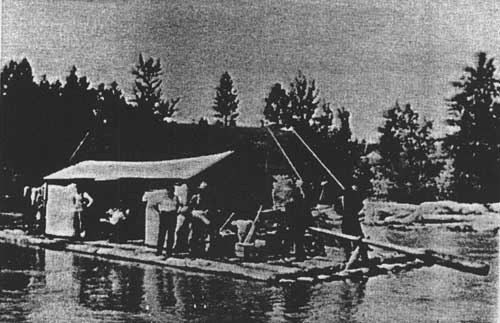

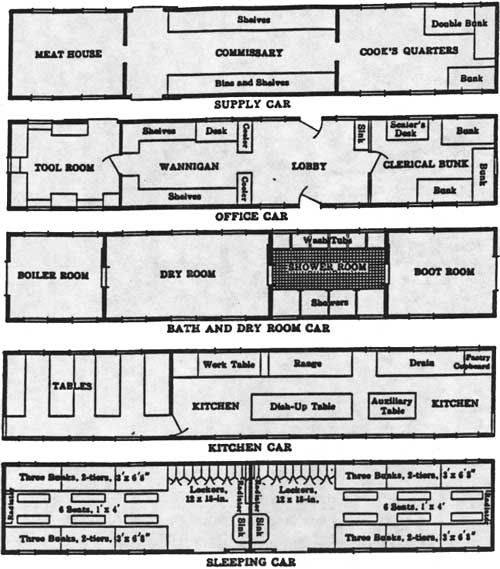

The Somers Lumber Company called for bids from logging contractors on the Swan Valley sale in 1913, but none were accepted. Instead, the company hired James E. Craney and his complete logging outfit to run the operation (Craney had built the spur railroad line from Kalispell to Somers). Several logging camps were set up, including one made of modular units on skids located on the logging railroad line and another made up mainly of tents. The land was clearcut and slash was burned on the sale. After the logging slash was broadcast burned, according to a Forest Service report, the small streams in the area went dry regularly in the summer (Craney 1978; Seattle RG 95, Flathead 1920-23 Inspection Reports, 9/11/22 memo; 18 December 1937 memo, Inspection Reports, Region One, 1937-, RG 95, FRC).

The Forest Service ranger stationed at Swan Lake scaled timber the winter of 1914-15 and spent subsequent winters looking after free-use permits and the government horses. About 150 men were working in the camps near the head of Swan Lake in 1918. Twelve families lived near the post office at the head of the lake, using boats to travel the lake in the summer and the "ice road" in the winter. The rest of the year a 7-mile wagon/automobile road provided the main access to the Flathead Valley (24LA149, FNF CR; Elwood 1980:200).

In 1919 a lunch fire broke out and burned over the entire sale area. Only about 5,700 acres of the 9,000 sold had been harvested; the rest of the timber burned in the fire (Stevens & Westphal n.d.:1).

Middle Fork

In 1899 H. B. Ayres wrote that an electric railroad might be feasible in the Middle Fork for hauling logs. Despite a growing demand for lumber east of the Divide, he felt that at that time none of the timber on the Middle Fork could be sold "at any price on the stump" because of transportation difficulties (Ayres "Lewis & Clarke" 1900:51, 67).

One early cordwood sale on Flathead Forest Reserve land was at Summit. The government sold approximately 253 cords to the Cut Bank Mercantile Company for 55.5 cents per cord. Timber sales continued slow but steady in the area. By 1918, small timber sales kept one man employed almost exclusively year-round out of Coram Ranger Station (14 February 1905 and 5 June 1905, "Rangers 1-1-05 to 6-30-05" pressbook, FNF CR; FNF "General Report" 1918).

Before 1908, the Forest Service offered small sales of cordwood, fence posts, and house logs to settlers along the railroad line up the Middle Fork. Timber was also harvested for administrative use as well. Timber harvest peaked in 1917 and then dropped again by 1920. In 1920, according to a report, "The area around Belton and Coram, adjacent to the Great Northern Railway and the river...has been cut over several times for logs, ties, poles, and finally for dead poles and cordwood. At present these lands are practically clear cut of merchantable timber and support only a partial stand of production." On the Coram Working Circle through 1959, 957,000 board feet were logged (FNF "Timber Management, Coram" 1961:40-41).

South Fork

In the early years, no contractor would buy stumpage above Devil's Elbow on the South Fork of the Flathead (approximately where the Hungry Horse Dam is now located) because the river flowed through a Z formed by sheer rock walls. Any logs that floated through the canyon would be battered and thus unfit for lumber (Frohlicher 1986:29).

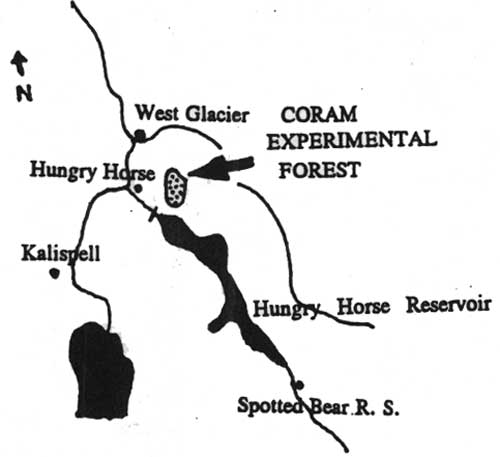

In 1933 the Forest Service established the Coram Experimental Forest in the South Fork drainage, 7,460 acres dedicated to research. This was one of only two experimental forests at the time (see Figure 94). Active research began in 1946 to study harvesting methods and the restocking of cutover land; later other resource management issues in western larch/Douglas-fir stands were also studied. The Flathead National Forest has remained responsible for fire protection, road maintenance, and timber sales within the experimental forest (Sneck 1977:7; "Facts about Coram Experimental Forest," box 3, folder 5, MSS 84, UM; Baker et al. 1993:149).

|

| Figure 94. Location of Coram Experimental Forest. |

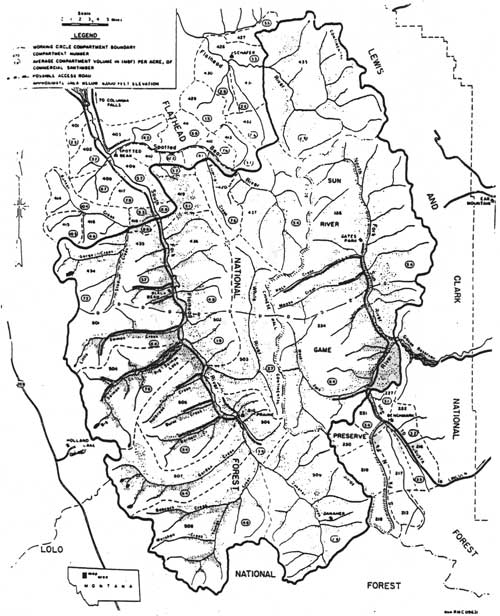

In the early 1960s a feasibility study of a timber sale in the Bob Marshall Wilderness concluded that the area should remain a wilderness because of high costs of road construction and low timber demand (see Figure 95) (Merriam 1966:91, 96)

|

| Figure 95. Hypothetical timber sale in the Bob Marshall Wilderness Area, mapped in 1960 (Merriam 1966:123). (click on image for a PDF version) |

North Fork and North of Columbia Fails

The accessible timber on the private land in the south part of the North Fork was cut out in the early 1920s. The ranger district wrote the first timber management plan in 1925, but no development occurred (FNF "Timber Management, Glacier View" 1959:4).

One of the early timber sales on the Forest occurred in 1909 in the Canyon Creek area. The logs were hauled by four- and six-horse wagons to Columbia Falls. In a typical timber sale, the J. Neils sale on Cedar Creek north of Columbia Falls, the company cut the best and most accessible timber and then asked to be relieved of cutting the rest. A Forest Service inspector commented that "Neils has this habit" (Thayer 1979; 27 December 1937 memo, Inspection Reports, Region One, 1937-, RG 95, FRC).

Two mill sites selected in 1912 and withdrawn by the Blackfeet National Forest included one on Hay Creek (a small water-powered mill had been built there some years ago) and one on Red Meadow Creek (which had no value then because there were "no timber sale activities in this region"). In 1916 the Hay Creek site was recommended to be released because no mill man could be convinced to establish a mill there (FNF "General Report" 1918; FNF Lands)

Logging During and Shortly After World War II

The national timber industry expanded rapidly at the end of World War II. Overcutting on many private lands compelled private timber owners to turn to the national forests; the Forest Service entered the market economy. The public and Congress both pressured the Forest Service to produce more timber. In 1940 national forests still provided only 3.2% of the nation's timber, but by 1970, Forest Service lands accounted for 18% of the national harvest. During the war, the standards of forest practice declined because of the pressure for more lumber. The national forests were not ready to meet the demand and spent most of the war years rushing to get into production. Meanwhile, industry overcut its stands. By the end of the war, though, the Forest Service was oriented towards commercial timber sales on a scale larger than ever before (W. Robbins 1982:237; Dana 1980:175).

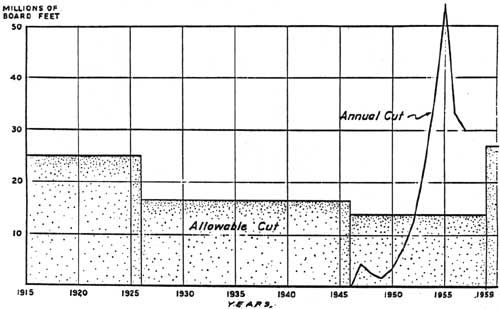

The Flathead National Forest's timber harvest increased dramatically during and after World War II. During the Depression, almost no timber had been sold. Shortly after the Depression, the Forest sold about 3-4 million board feet annually, but in 1944 the Flathead National Forest sold 31 million board feet. In 1955 the Forest sold 102 million board feet, representing just over 50% of the timber sold in the valley (see Figure 96) (Bolle 1959:73-74).

|

| Figure 96. Volume of timber cut on the Flathead National Forest, 1935-1960. The prices of Douglas-fir and Englemann spruce lumber per thousand board feet are also shown (from Bolle 1959:120f). |

Much of the valley bottom lands had been cleared of timber and planted to agricultural crops. From approximately 1900-1920 railroad logging and river driving brought logs to the large mills from the relatively flat benchlands of the larger drainages. The development of tractor skidding and truck hauling directly to the mill ponds allowed logging to be done on private lands all over the valley. At the same time, national forest stumpage came into demand, and the purchase of government timber to keep operating became accepted by all mill operators after the end of World War II (Ibenthal 1952:49, 52a).

As in other periods, desirable species shifted with availability and changing marketing and building construction techniques. In 1934 the value of various species was: western white pine, $8 per thousand board feet; ponderosa pine, $2-5 per thousand board feet; lodgepole pine, $1-4 per thousand board feet; other species, $0.25-2.50 per thousand board feet. In 1940 larch provided only 2.9% of the total cut of sawlogs in Region One, largely because of its weight and high shipping costs compared to Douglas-fir. By 1946 it was providing 21.9%; larch was used mostly in framing and concrete forms and had been approved for transmission line poles for the REA. By the 1940s, western larch was the leading species in northwestern Montana, and ponderosa pine had been increasing since 1935. Most of the ponderosa was being shipped to the midwest to be remanufactured into sash and doors. In 1946 the Forest Service announced a large sale of lodgepole from the Lewis & Clark National Forest. Before then it had been virtually unmarketable, but the demand grew (Brown 1934:209; R1 PR 963, 25 February 1946; Winters 1950:97; Sundborg 1945:14, 24; Baker et al. 1993:165).

During the war, the Forest Service offered timber sales in excess of normal sustained-yield limitations where forest products were needed to satisfy wartime requirements. To aid in the war effort, Congress made provisions for new access roads to open up new supplies of timber. Timber access roads built during 1943 and 1944 in Region One included two on the Flathead National Forest. The Emery Creek Project involved building 6 miles of road to gain access to a stand of white pine and larch. The road, built in 1944, allowed the harvesting of 10 million board feet of lumber in 1945; it was designed to run above the elevation of the flowage line of the proposed Hungry Horse Reservoir. The Skyland Road near Summit was also built in 1944 to harvest timber to meet wartime needs (Granger 1943:113; USDA FS "History of Engineering" 1990:420, 422).

The war-time boom led to the establishment of new small mills in the Flathead, many of them producing railroad ties because of the increased use of the railroads during the war (see Figure 97). The American Timber Company, for example, built a permanent mill on state land in the Lower Stillwater Lake area and cut ties during the war over a vast area. When the war was over, the portable mills switched back to cutting lumber (Cusick 1986:17).

| Year | Number of mills | Total reported production |

| 1869 | - | 13,000 |

| 1879 | - | 21,000 |

| 1889 | - | 94,000 |

| 1899 | 69 | 255,685 |

| 1904 | 36 | 236,430 |

| 1905 | 23 | 189,291 |

| 1906 | 84 | 328,727 |

| 1907 | 130 | 343,814 |

| 1908 | 173 | 311,533 |

| 1909 | 179 | 308,582 |

| 1910 | 140 | 319,089 |

| 1911 | 126 | 228,416 |

| 1912 | 118 | 272,174 |

| 1913 | 109 | 357,974 |

| 1914 | 124 | 317,842 |

| 1915 | 94 | 324,333 |

| 1916 | 103 | 383,884 |

| 1917 | 122 | 347,496 |

| 1918 | 98 | 335,811 |

| 1919 | 125 | 287,378 |

| 1920 | 124 | 409,667 |

| 1921 | 120 | 213,989 |

| 1922 | 100 | 303,458 |

| 1923 | 117 | 426,917 |

| 1924 | 100 | 350,335 |

| 1925 | 120 | 388,854 |

| 1926 | 122 | 378,698 |

| 1927 | 127 | 398,267 |

| 1928 | 119 | 387,879 |

| 1929 | 126 | 388,711 |

| 1930 | 114 | 296,990 |

| 1931 | 86 | 158,213 |

| 1932 | 72 | 111,048 |

| 1933 | 89 | 125,126 |

| 1934 | 105 | 171,841 |

| 1935 | 116 | 233,633 |

| 1936 | 126 | 295,233 |

| 1937 | 146 | 335,045 |

| 1938 | 140 | 221,579 |

| 1939 | 168 | 271,096 |

| 1940 | 168 | 325,338 |

| 1941 | 265 | 373,970 |

| 1942 | 249 | 433,089 |

| 1943 | 228 | 423,520 |

| 1944 | 256 | 448,498 |

| 1945 | 253 | 341,749 |

| 1946 | 401 | 413,859 |

| 1947 | 407 | 499,959 |

| 1948 | 434 | 597,944 |

| Figure 97. Number of sawmills and lumber production in Montana, selected years 1869 to 1948 (from Kemp 1950:6). |

Over 700 Region One Forest Service employees served in World War II. As in World War I, companies of Forest Engineers were sent overseas to provide timber for the troops they served. The Forest Service and other agencies contributed technical knowledge and personnel (Baker et al. 1993:163; Winters 1950:23-24).

World War II touched ground on Flathead National Forest land in a rather strange way in December of 1944. Two woodcutters working 17 miles southwest of Kalispell found a Japanese balloon on the ground containing a bomb that had failed to explode (Webber 1984:261).

On the home front, woods work was considered essential work, so local logging contractors did not face a shortage of workers during the war. Camps for conscientious objectors were located on various national forests. In the Flathead, conscientious objectors were based in Glacier National Park.

The building boom following World War II led to pressure for the increased harvesting of timber on national forest lands. After the war, the home construction industry boomed. Consumers' purchasing power had accumulated, and rehabilitating war-torn Europe also led to a market for American lumber. Timber management ceased to be largely custodial. At the end of the war, 57% of the commercial forest land in Flathead County was national forest land, and much of it was targeted for harvesting. As historian Harold Steen put it, "Following the war there was broad agreement for the need to step up the tempo of logging on national forests" (Steen 1976:280; Sundborg 1945, appendix 7).

The significant growth in the Montana timber industry began in 1946. The increase in logging was due to a national backlog of demand for housing, price increases for stumpage and lumber, and the depletion of timber in other regions. Five plywood mills moved into Montana between 1955 and 1964, three of them to the upper Flathead, partly because of the growing interest in western larch as a veneer species. The post-war timber boom ended at the end of 1956. In 1957, the number of operating mills dropped from 104 to 60 in one year (Bolle 1966:19-20).

The Flathead National Forest, like national forests around the country, increased its annual cut following World War II. The Forest reached the allowable cut it had set for itself of 60 thousand board feet for the first time in 1947. The allowable cut remained at this level until 1957, although it was exceeded some of those years. This allowable cut figure was later more than doubled due to better inventories and improved silvicultural and utilization practices. The timber program dominated the agency's workday as it never had before (Merriam 1966:70; Shaw 1967:124; Clary 1986:122, 125).