|

CCC Forestry

|

|

Chapter VII

FOREST UTILIZATION

|

THE term "utilization" in its broadest sense means "using in any form." Webster defines utilization as "turning to profitable account or use." Forest utilization as a term is not so wide it its meaning. Illick defines forest utilization as "converting standing timber and other forest products into forms and commodities usable by mankind." This would include methods of logging, milling, and marketing. As these phases of utilization were discussed in the previous chapter, they will not be considered here. When one goes into the forest for recreation, he is using it. The artist utilizes forests when he paints a panoramic forest scene. Farmers utilize them when they use water from wooded mountains for irrigation. In general, however, forest utilization is concerned with the use of the major product, wood, and such other products as may be derived from growing forests. The earliest and most important use of wood was for protection. When the ancient tribesman built a temporary shelter from fallen poles and bark, he began to use wood to protect himself against the forces of nature. When he attached a wooden handle to his stone club head, he began using wood to protect himself against his living enemies. When he crept to a burning tree ignited by lightning; he first used wood as fuel. Bark shelters grew into thatched huts, huts into cabins, cabins into frame buildings. Bows and arrows, crossbows, catapults, and battering rams show the evolution of wooden weapons. Rafts initiated the use of wood in transportation. Rafts were followed by dugouts, dugouts by boats, boats by sailing vessels. Great schooners eventually made possible vast world trade and great navies. Early locomotives ran on wooden rails. Gradually many materials have been substituted for wood, but the vast amount of wood yet in demand assures its continued use as a raw product. |

Forest Utilization: Making Forest Products Usable. Wood for Protection.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

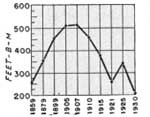

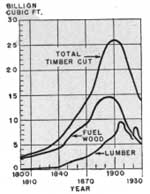

WOOD CONSUMPTION In order to determine forest policies and plan for forests to meet future needs, it is necessary to study the consumption of wood. To know how wood will be used tomorrow, it is necessary to know how wood was used yesterday and how it is being used today. The use of wood in America has fluctuated greatly with the rising population. This may be indicated by a study of the per capita consumption of lumber. A century ago the use of lumber per person was about 75 board feet each year. With the industrial expansion, increased immigration, and great annual increases in the number of farms, the use of lumber grew year by year until the peak came in 1907 with per capita consumption of 525 board feet. At that time industry began releasing more substitutes for wood, and immigration was curtailed. Previously, farms had been increasing at the rate of 90,000 a year. That increase declined, and likewise, the use of lumber declined, reaching the low figure of 275 feet per capita in 1929. Since that time drastic decreases in demands have been largely due to a decline in construction brought about by the general economic depression. As shown by the accompanying figure, the amount of timber cut increased from 2-1/2 billion cubic feet in 1800 to 26 billion in 1900. Of this amount, 14 billion feet were used for fuel and 7 billion for lumber. The use of coal and gas for fuel caused a decline in the use of wood for that purpose. This was fortunate, because at the previous rate of increase, the country would have been stripped of its forests in another half century. By 1930 the fuel wood cut was down to 5 billion cubic feet. This amount will probably decline further, whereas lumber cut will probably fluctuate for a time and then settle to a cut which will balance wood growth and consumption. The United States has always used wood freely. The per capita use of wood here exceeds that of all other nations except a few sparsely settled ones where very extensive forests exist. In table 1 the 1929 per capita consumption of wood in the United States is compared with that of European countries. TABLE 1.—A comparison of the wood consumption in the United States with that in European countries

Table 2 indicates how the 14-1/2 billion cubic feet of timber which is cut each year in the United States (average 1925-29) is used. TABLE 2.—Annual wood use in the United States (average 1925 to 1929)

The decrease in world consumption of wood does not mean that wood is becoming obsolete. Shortage in available supplies and economic difficulties resulting from business depressions have caused the decreases. This reduction of the demand for lumber through substitution of other products for wood is in part offset by an increase in pulpwood requirements. Fiber and cellulose products are increasing in demand. These call for more pulpwood. Because of the high transportation costs of coal, fuel wood also will long be desired, especially on farms and in regions where wood is plentiful. The extent to which other materials are to be substituted for wood depends on how effectively wood can be made to meet use requirements as compared with competing materials. Wood has outstanding advantages as a low-cost building material, and will play a large part in Federal housing activities, the objective of which is to supply modern low-cost homes. Recent developments in the use of metal timber connectors and in the use of structural plywood are creating new demands for wood in construction. Definite progress has been made in treating wood to make it resistant to shrinkage, swelling, fire, decay, and insect attack. |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

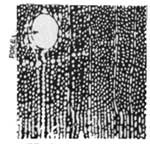

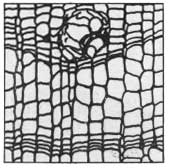

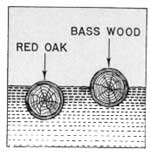

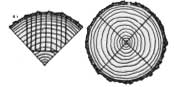

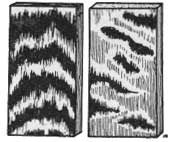

Woods of different tree species have different properties which affect their use. The science of wood structure and properties is known as wood technology. The usability of wood depends upon its properties—weight, grain, color, durability, hardness, and other characteristics. The available supply of a species as well as the demand for it determines its cost and affects its use. As has been shown before, tree species are divided into hardwood and softwood classes. Some so-called hardwoods are softer than some woods in the softwood class. Some of the pines (softwoods) are harder and more resistant to decay than cottonwoods (hardwoods). Some types of wood are especially strong, stiff, and durable. Oak, Douglas fir, and longleaf pine are well adapted for heavy construction. Hickory and ash are very strong and tough, and therefore valuable for tool handles. Because they do not decay easily, cedar, cypress, locust, and chestnut make excellent posts. Some softwoods not suitable for construction in which heavy loads must he carried, may be worked very easily and used where great strength is not essential. For instance, soft pine and similar woods may be used for sheathing or subflooring. The woods of spruce and aspen have fine texture which makes them valuable for paper and other pulp products. White oak is strong and has closed pores, and therefore makes excellent cooperage. Black walnut, oak, cherry, maple, and mahogany have beautiful grain and may be finished to make desirable furniture and cabinets. Often less valuable species of wood are substituted for the better ones in cabinetmaking, and synthetic coloring and finishing are used to imitate the more valuable woods. The structure of a wood determines its qualities and characteristics. The composition and arrangement of cells in different species is responsible for differences in structure. As has already been explained, the trunk of a tree is composed of heartwood, sapwood, cambium, and bark. The heartwood is composed of dead cells, and is usually darker in color than sapwood. Sapwood is composed of living cells and varies in thickness in the different species. Wood cell arrangement has been explained in Chapter I. In the hardwoods, large vessels extend along the grain. These appear to the naked eye as small holes or pores. Such wood is known as porous, as opposed to nonporous (coniferous) wood in which these vessels do not appear. Some hardwoods, the oaks for instance, develop large pores in the springwood and smaller ones in the summerwood, so that a definite line of pores can be seen in each growth ring. Such wood is known as ring porous. When, as in maple, the pores are more or less uniform in size and consistent throughout the ring, the name diffuse porous is applied. Wood has thin planes of tissues which extend ribbonlike across the grain of the tree. These strands of tissue are called rays, and their function is to carry sap radially through the other cells. They give strength and beauty to wood, and present beautiful surfaces when the log has been quarter-sawed. Oak and beech have well-developed rays, but in many species the rays can scarcely be seen. Weights of woods vary with the species. Some of the heaviest are maple, elm, white oak, hickory, longleaf pine, and Douglas fir. Aspen, yellow poplar, chestnut, white pine, hemlock, and redwood are lighter species. Heavier woods rarely will float before they are seasoned. |

Fibrous.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

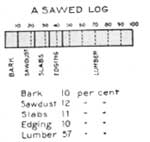

USE OF FOREST PRODUCTS The products of the forest may be classified as follows: (1) Lumber, (2) timbers, (3) bolts, (4) fuel wood, (5) pulpwood, (6) distillation wood, (7) miscellaneous products. Lumber includes strips, boards, and dimension material, which is used both in construction and in manufactured products. Timbers may be subclassified as round and square. Square timbers are sawed or hewed beams and timbers used in heavy construction. Railroad ties also fall in this class of timber products. Round timbers include poles, posts, piling, and mine timbers. Bolts are short logs, used in making staves, shingles, veneer wood, and excelsior. These are often split in the woods to facilitate handling. Fuel wood is of different sizes and lengths, and includes all wood used for heating purposes. Pulpwood is used to make pulp for paper, boards, or cellulose products. Distillation wood is used to obtain wood alcohol, turpentine, tar, and some acids, with byproducts such as charcoal and acetate of lime. Hundreds of miscellaneous forest products add to forest values. Among these the most important are naval stores (turpentine, tars, and resins), rubber, cork, medicinal products, and nuts, sugar, and sirup.

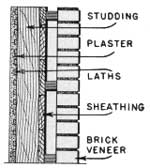

USE OF LUMBER IN CONSTRUCTION In 1929 the United States used 32 billion board feet of sawed timber, which was about half the total wood cut. Approximately two-thirds of this went into construction. The greater part of this lumber was used in erecting buildings, principally residences. Other forms of construction utilizing wood are fences, bridges, scaffolding, and concrete forms. Although many materials have been substituted for it, construction still depends largely upon wood. Lumber is used for concrete forms, and brick buildings are often framed with wood. Masonry buildings are commonly finished and trimmed with wood. Wood is the standard material for construction of low-cost buildings. It is especially adapted to use in small dwellings, and farm buildings are almost universally made of wood. The forest furnishes material which contributes greatly to the general advancement of the human race. Probably its best contribution is in providing material with which to build homes. The success of a nation depends upon the happiness and well-being of its families. The forest cannot better be utilized than in furnishing material for homes, residences, and for other construction. LUMBER IN MANUFACTURING In 1928, a total of 18,683,758,000 board feet of lumber was remanufactured. This is probably a typical year, since it is midway between the boom year of 1923 and the lowest depression year, 1933. Products manufactured from wood are divided into many classifications. Table 3 shows the amount of wood used in a few of the large industries, and indicates the surprising demands for wood for smaller, seemingly unimportant articles.

Much of the lumber used would be wasted were it not for the close utilization which manufacturers are learning to practice. First-class lumber is necessary for manufacturing cabinets, refrigerators, etc. Small pieces left from cutting, which would otherwise be wasted, may be worked into handles, furniture parts, woodenware, and novelties. We can hardly believe that the manufacture of toys requires annually more than 39 million board feet of lumber, that for toothpicks more than 7 million feet are required, and that tobacco pipes alone require 87 thousand board feet. Table 3.—Lumber used in the manufacture of some minor products in the United States, 1928

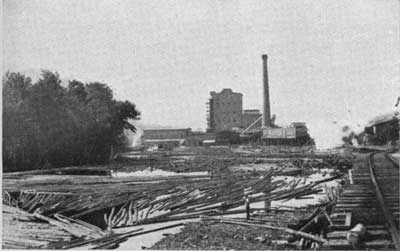

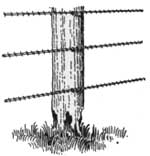

TIMBERS Timbers include poles, piles, posts, ties, and mine timbers. Poles and piles are round, but posts and mine timbers may be either round or split. Cross ties are hewed on two or four sides, or they may be sawed. Timbers are usually derived from immature trees. Forests are often thinned and the products of these thinnings worked into timbers. By utilizing in this way young trees removed from the stand, forests may be made to pay for their maintenance while the crop trees are maturing. Poles are used principally for telephone and telegraph lines and piling. During 1929, 4,557,000 poles were used for wire hanging alone. Long straight trees are required for poles and piles, and smaller trees may be worked into fence posts. More than 100,000,000 fence posts were used in 1929. Experiments with substitutes for wood as posts have proved that iron or concrete posts are practical. The number of fence posts of material other than wood now in use, however, is negligible. Suitable substitutes for wooden ties for railroads have not been found, although many materials have been tried. Wooden cross ties afford a resiliency which helps to absorb the shock of heavy rolling stock traveling over steel rails. Cross ties under our present 430,000 miles of railroad have to be replaced at the rate of about 150 ties per mile annually. In 1929, railroads purchased 95,521,207 ties. Most of the ties used are hewed. Mine timbers are used in many different lengths and sizes, principally for track ties and props. Sawed mine timbers are included in lumber statistics. Most mine timbers, however, are round or split. An average of 184,875,000 cubic feet of round timbers was used annually from 1925 to 1928. PULPWOOD Paper towels and napkins, and paper cups and plates are used by millions. Even paper clothing and paper shoes are now worn. The people of the United States are the greatest paper users of the world. Most of the paper now used is made from wood. Seventy years ago rags were the principal raw materials for paper manufacture. Pulp made from straw, grass, and cornstalks has recently been substituted for wood pulp, but wood, being high in cellulose compounds, is the best raw material for paper making. Thirteen and one-half million cords of pulpwood are used annually in the United States. Practically all this wood goes into paper making. Paper products are divided into six groups: (1) Boards, (2) newsprint, (3) wrappers, (4) book paper, (5) fine paper, and (6) miscellaneous products. Boards include paper used for carton and packing cases, and fiber boards used for ceiling and insulation in buildings. The bulk of our paper product is made up of the different kinds of fiber board. Not so much wood is used in boards, however, as in newsprint, since old paper is utilized in their manufacture. The use of fiber board as a wood product is increasing. Newsprint is paper used in newspapers. Millions of tons are used annually. The average number of pages in newspapers increased from 7 in 1890 to 30 in 1930. Increases in population, literacy, and advertising have caused this growth in newspaper size. The second greatest use of paper is for wrappers. This form of paper is used by everyone. The annual consumption is over 1-1/2 million pounds. Book stock requires a better quality of papers. Consumption of paper for this purpose is little less than for wrapping paper. Fine papers are higher grade papers used for print stock, writing paper, fine wrappers, and such products. Miscellaneous paper products usually include manufactured products, such as papier mâché, wall papers, and fabricated articles. The per capita consumption of paper products in this country for 1929 was 199 pounds. In 1933 the principal use of the total product was as follows:

The manufacture of paper is one of the great industries of the United States. In value of product and number of people employed this industry ranks high. More than 197,000 people in the United States were employed in the manufacture of paper and paper goods in 1932. In Canada paper making leads all industries.

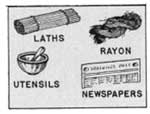

Paper is manufactured by two methods, mechanical and chemical. In the mechanical process the logs are ground to a pulp by machinery. This leaves all the rough material in the pulp and consequently produces a coarse-grained paper. In the chemical process, chemicals are used to break up the wood fibers and to dissolve them into a better form of pulp which makes finer paper. There are three chemical processes for pulping paper—soda, sulphite, and sulphate processes. Mechanically pulped paper is valued at about $22 per ton while chemical paper is valued at about $40 per ton (1935). Pulpwood for making cellulose products is growing in demand. The rayon and cellophane industries are offering new products to meet the requirements of consumers. Rayon, formerly called artificial silk, is competing with other textile products, especially silk. Articles are wrapped and protected by cellophane, and, although it is a new product, the consumption is about a hundred million pounds annually. An American who had been living abroad for 8 years was asked upon his return what he considered the most noticeable change in his native country. He replied that the greatest change was that everything was wrapped in cellophane. In making rayon and cellophane, wood is pulped to obtain free cellulose. This is treated with a solution which dissolves it. It is then forced by enormous pressure through spinnerettes to form rayon threads or through slits to form sheets of cellophane. BOLTS Bolts have recently been in great demand because of increase in the quantity of cooperage products. Staves for barrels are of two classes. Tight cooperage staves are used for barrels and casks for holding and storing liquids. Loose cooperage is used in making barrels for dry materials. Bolts for tight cooperage must be of flawless timber. Bolts are used also in making heads for tight barrels. The yearly average of staves used during the period 1925 to 1929 was 307,167,000. Loose cooperage required three times as much material as tight cooperage but of an inferior quality. Shingles also are manufactured from bolts. The average yearly production of shingles for the period 1925 to 1929 was more than 6 million. Demands for veneer bolts (often in log sizes) are increasing. The manufacture of veneer is a very interesting process, in which thin strips of wood are shaved from revolving logs, which have been softened by steaming. The process resembles the drawing of a continuous strip of paper from a large roll. Almost a billion board feet of logs and bolts have been used annually for veneering. FUEL WOOD The use of fuel wood has decreased because more practical fuels are becoming popular. Gas, electricity, coal, and oil are used today, but in timbered sections remote from coal fields, wood fuel is still prevalent.

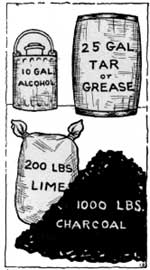

Fuel wood, like posts, may be a byproduct of other forest crops. It may be salvaged from logging operations or from thinnings. The bulkiness of firewood prevents its being transported great distances, and consequently it is limited to local use. Fuel wood, as a forest product, is second to saw timber in quantity produced. Specifications in size and type rarely limit the use of fuel wood. It is measured by cords. The yearly consumption (1925 to 1929) was 61 million cords. As long as fuel wood is confined to inferior timber and to salvaged wood, its use may be encouraged. DISTILLATION WOOD Wood is composed of cells. The cell walls are made up of cellulose and lignin. There is more than twice as much cellulose as lignin in cell structure. Within the cells are water, carbohydrates, oils, tannins, dyes, resins, proteins, and acids. When wood is heated in the absence of air, the cells break down. Gases are formed which may be condensed into alcohol and acids. Most of the distilled products are taken from hardwoods. Heavy compact woods contain more of these materials than lighter and softer woods. Oak, beech, maple, and birch are perhaps best for this use. A few years ago, a million cords were required annually for distillation products, but the demand is not so great at present. In addition to strictly distilled products, charcoal, tars, and chemicals are obtained from wood in the distillation process. A cord of wood distilled by modern methods will yield about 10 gallons of wood alcohol, 25 gallons of tar and grease, 200 pounds of acetate of lime, and 1,000 pounds of charcoal. The crude alcohol may be refined to produce pure wood alcohol, acetic acid, and acetone. Dyestuffs, volatile oils, tannins, and turpentine may be obtained from wood by boiling or steaming it. The dyes are not very important at present as many mineral dyes are being used. Oils, however, are important in making medicinal supplies, antiseptics, and preservatives. Some oils are used in making soaps, perfumes, and flavors. Turpentine may be extracted from roots and heartwood of pines rich in resin, but extracted turpentines and tars are not as important commercially as gum products. MISCELLANEOUS WOOD PRODUCTS Hundreds of forest products not already classified increase the usefulness of the forest. The most important of these are naval stores and rubber. Turpentine is made from resin taken directly from the growing tree. A cut is made so that the resin flows out. This is collected and distilled to obtain turpentine, tar, and pitch. Formerly, a great deal of tar and pitch was used in calking wooden ships. Hence the name "naval stores." The Southern States produce more than half the world's supply of naval stores. Slash and longleaf pines, which are the best sources of resins for this product, are abundant in the region. Raw rubber is obtained in the same manner as gum for naval stores. The sap from rubber trees is known as latex and goes directly into rubber production. Rubber forests grow in tropical countries, and at present many plantations supplement the supply obtained from the natural rubber forests. Although little rubber is produced directly in the United States, the manufacture of rubber products is one of the country's greatest industries. Cork is the bark of the cork oak and is an important forest product. It is produced principally in Portugal and Spain. Fruits, nuts, and extracts from forest trees add their values to the host of others. Walnuts, hickory nuts, beechnuts, chestnuts, pecans, and berries bring income to natives who have access to the forest. The manufacture of maple sugar and syrup has developed commercially in several States. Many plants and trees furnish pharmaceutical and medicinal supplies. While some of these are now produced synthetically, the forest is still important for medicinal products. Decorative materials such as Christmas trees, holly, mistletoe, ferns, and flowers may be classed as forest products. The business of collecting, preparing, and marketing the products employs thousands of people, and involves expenditures of millions of dollars every year. Part-time work in the harvesting and selling of minor forest products provides an income for many rural dwellers who otherwise would be almost entirely dependent upon garden crops. Seasonal market demands for many forest products often coincide with lulls in farm activities. |

Wood Pulp Best Raw Material for Paper.

Wrappers. Bookstock and Fine Papers.

How Paper Is Used. Employment. Manufacturing Processes.

"Everything Wrapped in Cellophane."

Other Wood Extracts.

Rubber Latex.

Cork. Medicinal Products.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DECREASING WOOD WASTE It has been estimated that only a third of the tree is actually used. Much of the two-thirds usually wasted should be salvaged. Wood left in stumps, limbs, bark, slabs, and sawdust constitutes the greatest wastes in lumbering. Development of byproducts, and the utilization of piece wood in making small articles will decrease this loss. Pulp products such as rayon, wallboard, insulation, and pressed wood can also utilize parts of the tree now not used. If slabs and edging can be used in making small articles such as lath, toys, and novelties, lumber which otherwise would be wasted may be saved. Improved logging practices may reduce waste in the woods. Use of saws with small kerfs (thickness of cutting edge) saves timber at the mill. The efficient sawyer decreases waste. INCREASING WOOD USAGE The use of wood depends largely on economic conditions. In times when business is active and economic conditions are good, much wood is used. Lumber production and consumption decreased more than 50 percent from 1929 to 1931. The economic influence cannot be controlled by foresters but there are ways by which consumption can be increased. Prevention of waste and close utilization will help to lower the cost of wood products so that they can compete with wood substitutes. Making wood products more desirable will create a greater demand for them. Quarter sawing, for instance, instead of plain sawing makes wood more valuable. In quarter sawing the logs are quartered and boards are sawn parallel to the rays. Although this may increase waste it brings out the grain and makes the wood more attractive. Treating new lumber with chemicals to prevent discoloration makes it more attractive as well as more useful to purchasers. Proper seasoning and storing also render lumber more valuable.

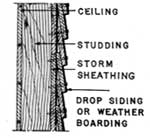

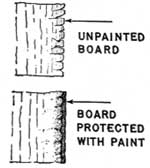

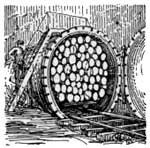

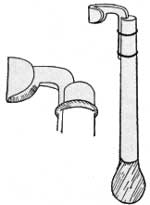

It is not possible to foresee the exact status of wood in the future. There seems to be great possibility in the chemical utilization of wood. Use of the cellulose content of wood cells has been explained. The number of products recently made possible through chemical treatment seems to point to a new field of utility for forest products. PRESERVING WOOD Much has been said about forest protection. Protecting the forests to bring about greater wood production is a basic economy. Treating wood to protect it from rapid deterioration, insect attacks, and decay is another basic economy. Some lumber dealers have argued that treatment of wood to prevent decay would decrease the lumber business. However, selling lumber that will decay quickly in hopes of increasing lumber consumption would be similar to manufacturing automobiles that would wear out quickly, in the hope of selling more machines. Decay in wood is caused by fungi which live on the wood cells and bring about their decomposition. Fungi live and work best in moist wood. If wood is to be preserved, it must be kept dry. This can be accomplished in part by protection of roofs and eaves, and by building practices designed to shed water such as using drop-siding or weather-boarding on the outside of buildings. Another common practice which helps to preserve wood is painting. Paint has both esthetic and preservative values. It beautifies and partially seals the pores of wood against moisture and spores of fungi. Chemical treatment of timber is a growing industry. Progressive lumber dealers believe that it will encourage the use of lumber and will prevent substitution of materials that are more lasting than untreated wood. The most common preservative is coal tar creosote. Its cost is reasonably low. It prevents wood-destroying fungi, repels wood-eating insects, partially seals pores against water, and does not readily evaporate or leach from the wood. All these requirements are essential in a good preservative. There are several methods of applying creosote and other preservatives. Before any preservative is applied, the wood should be seasoned and dry. The brush method is used for painting and for light applications of creosote. The preservative may also be sprayed on the surface of the wood. Creosote-base stains of various colors may be used on rough surface not adaptable to painting. Dipping is faster than the brush method and permits better penetration of the fluid. If both the preservative and the wood are heated, the preservative will permeate more readily. The best permeation is obtained when the preservative is heated to a temperature of about 200° F. If timbers which have been heated in creosote are cooled in a tank of the fluid at a temperature of about 100°, the preservative penetrates the wood better than if it is permitted to cool in open air. Dipping is known as the open tank method. It is a good method for partial treatment as used on poles and posts, when only the part to be set in the ground is treated. A small tank or a barrel set over a simple furnace may be used to hold the fluid and the upright posts. For railroad ties, paving blocks, and other items demanding heavy treatment, the pressure method has been developed. There are several pressure processes in use. The most complicated one utilizes steam, air pressure, and vacuum in injecting the preservative into the wood. Special tanks and processes provide for forcing the compounds into the pores of the wood. Under this method the wood (well seasoned) to be treated is sealed in pressure tanks. It is steamed under pressure to open the pores. Steam and excess moisture is then drawn from the wood by subjecting it to a vacuum. Next the hot preservative is introduced through pipes. The air pressure in the tank is then increased until the fluid is injected deep into the wood fiber. The amount of liquid applied may be regulated by changing pressures to fit. the requirements of the different wood species and according to the degree of penetration desired. |

Millions of cords of pulpwood are consumed annually in the United States for paper and cellulose products.

A Bad Theory.

Essentials of a Good Wood Preservative. Brushing. Dipping.

Open Tank.

Pressure. A Vacuum. Then Pressure.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SUMMARY Forest utilization is concerned with the use of the products of the forest. The principal forest product is wood. The usability of wood depends upon its characteristics and properties. A great deal of useful wood wasted in logging and manufacturing could be advantageously used. Wood products are classed as lumber, timbers, bolts, fuel wood, pulpwood, distillation wood, and miscellaneous products. Construction of residences creates the greatest demand for lumber. Nearly every type of construction demands the use of some lumber. Wood seems to be the most practical material for construction of rural homes. About 32 billion feet are used annually. Of more than 18 billion board feet of lumber used in manufacturing in the United States in 1928, boxes and crates required nearly 5 billion feet. Hundreds of other manufactured articles require varying amounts. At the bottom of the list are tobacco pipes, for which 87,000 board feet are used. Pulpwood is used in the production of paper and cellulose products. The 13-1/2 million cords of pulpwood consumed in this country are used to make fiber boards, newsprints, wrappers, and book stock. Rayon and cellophane are the two major cellulose products made from wood pulp. Bolts are used for cooperage, shingles, veneer, excelsior, and a few other small wood products. Fuel wood is used in great quantities where wood is plentiful and where gas and coal are not found. Distillation wood yields alcohol, acids, tars, grease, oils, and dyes. Naval stores and rubber are important forest products used in abundance. Decorative materials are supplied from forests, especially for Christmas seasons. Proper forest utilization is important in that smaller areas of forests must now furnish many more people than formerly with products. Wider utilization of forest products may be brought about through systematic management and scientific knowledge, and through a more universal use of forests for their influences and recreational values. |

Wood Consumption. Refer to Table 3. Wood Products. 13-1/2 Million Cords.

A New Field of Utility for Forest Products. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| <<< Previous | <<< Contents>>> | Next >>> |

|

ccc-forestry/chap7.htm Last Updated: 02-Apr-2009 |