|

CCC Forestry

|

|

Chapter IX

LUMBERING

|

THE combined processes required in taking timber from the forest and converting it into usable forms are known as lumbering. Lumbering may be divided into two main processes, logging and milling. Forestry is concerned with logging more than with milling, since the latter is more related to the manufacturing industry than to the science of forestry.

The movement of logging centers was shown in the third chapter. This movement has brought new methods and new machinery to the logging industry. Logging practices today are varied, depending upon topography and species. Early logging was done with the ax, and logs were transported by ox team. A whipsaw was used for converting logs into lumber. This was a long saw, operated by two men, which ripped boards lengthwise from logs. The first sawmill in this country was established about 1631 in Maine. This small mill driven by water-power and cutting only a few hundred feet of lumber a day, was very crude compared with some of the large mills of today, with a cutting capacity of nearly a million feet a day. Trees may be felled with power saws, transported entirely by machinery, and sawed by buzzing band saws. However, not all lumber is cut in large mills. Such mills are practical in extensive stands where the supply will not be depleted for years, but on limited tracts small portable mills are used. These small mills cut 75 percent of the lumber in some areas. They are located principally in New England and in the southeastern pine region. |

Forestry and Lumbering.

Before Sawmills Came into Existence, Sawing Was Done with Whipsaws.

The Small Sawmill Is Very Important in Lumber Production. | |

|

LOGGING Logging may be divided into several minor processes. These are marking (explained in Ch. 6), measuring (explained in Ch. 8), felling, lopping, bucking, skidding or yarding, and transporting.

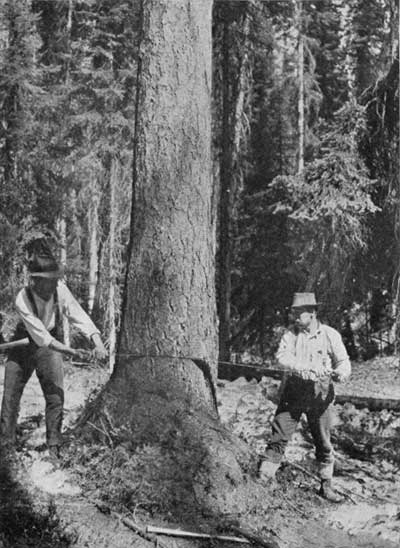

FELLING Trees are felled principally by hand, although motor-driven cross-cut saws have been devised. These are bulky and unwieldy, especially on rough land. In felling, a notch is cut in the tree to help in directing the fall and to prevent splitting and breaking of the bole. The tree is then sawed off from the side opposite the notch. Trees should not be felled on other timber or young growth because of possible damage to them. Precautions should be taken to fell the tree on as smooth ground as possible, since a tree falling across stumps or large stones may shatter or break, and is sure to be difficult to cross-cut. Sometimes large trees are felled into "cradles" made of brush. These cushion the tree and prevent breaking and splitting. The direction of the fall depends upon the lean of the tree, the wind, and the undercut notch. A tree standing straight may be thrown in the direction desired by notching it on the side facing the intended direction of fall. A wedge is driven into the saw cut to prevent it from closing on the saw. Heavy wedging is necessary when the desired direction of fall is contrary to the lean of the tree. Trees should be sawed close to the ground, even though this slows the felling process. In logging the big redwoods of the west coast, the stumps are usually left high because trees have considerable ground swell. Saws from 12 to 18 feet in length are required, and springboards are attached for sawyers to stand on while felling the tree. A springboard is about 8 inches wide and 5 feet long. It has an iron "toe" attached to one end which holds it in a small notch chopped in the side of the stump at the required position. Springboards are not being used as extensively as they once were because lumbermen are cutting stumps lower. Power saws are also being used more in felling big timber. TRIMMING The limbs are trimmed from the tree trunk. This is called lopping or limbing. In limbing trees, care should be taken to trim the branches off smoothly so that no snags or knots are left on the logs. In order to keep the top of the tree from breaking and to protect trees nearby, woodsmen often trim and top the tree before felling it. This is one of the most difficult jobs in logging and requires skillful work. BUCKING Cross-cutting the fallen tree into logs is called bucking. Small trees are usually bucked into logs by a two-man crew, while big trees, such as the redwoods, are more often bucked by a single workman who uses a one-man saw. This eliminates the scaffolding on each side of big logs which would be required for two-man bucking. Experienced loggers know many tricks that aid in cross-cutting trees having a bad "lie." Sometimes the cut must be made from below. Wedges must be driven in to keep the wood from binding the saw. Various forms of false work and jacks are used to aid in bucking. In sawing pine, resin and gum gradually collect on the saw until it cannot be drawn. It is necessary to sprinkle the saw often with kerosene to remove this gum. A bucking crew working in pine usually carries a jug of kerosene and a bottle with a stopper of pine needles which permits sprinkling.

|

Bucking trees into logs. Note measuring stick, wedges, and sledge.

| |

|

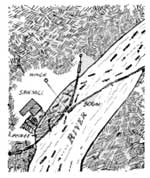

TRANSPORTING LOGS Although methods of felling and bucking have not changed greatly for a century, methods of transportation have shown decided departures from old methods. However, the old methods are used today in some sections and on small jobs. In early timber operations logging was done as near streams as possible and logs floated or driven to mills. Since railroads and motor roads now reach more timbered areas, streams are not utilized so much as in the past. SKIDDING After logs are cut, they must be collected so that they may be taken out of the woods in loads as large as possible. Collecting logs to the skid way is commonly known as skidding. Horses, mules, and oxen may be used in collecting, but the day of oxen has almost passed. Once they were practical, and in large timber five or six yokes were sometimes used to drag out heavy logs. In small timber, especially in the East, mules and horses are used to drag or skid the logs along trails which have been "swamped out" (brush and small trees cut) through the woods to skidways on secondary trails; or the logs may go directly to the yard on the main road or stream. A yarding sled or a "lizzard" may be used to keep the front end of the log off the ground to make dragging easier. Yarding carts are also used where the ground is not too steep and the character of the woods and trails permit it. Some yarding carts are known as self-loaders, because they are so constructed that the team is used in loading the yarder. On large operations and in big timber, much of the collecting is being done by cables and steam power. Wire cables are stretched from tall trees to an engine, and steam winches are located near the road. Logs are hooked and carried on traveling pulleys along the high line. Sometimes a long line is dragged out by workmen and attached to logs on the ground, and the cable is rewound on the drum of the winch, thus snaking the log along the ground to the yard or skidway. This is called the low-line method. Where topography will permit their use, caterpillar type (track-laying) tractors are used. They drag the logs directly on the ground, or carry the front end by a yarding arch, similar to the lighter yarding cart. The logs are raised by motor power and the front end is slung under the heavy arch of the yarder. The tractor can tow huge logs by this method and is able to travel over very rough ground. Yarding arches are used principally in the West where large companies operate in big timber. LOG HAULING After logs have been collected, they are transported to primary roads, railroads, or streams. Three or four different methods of transporting may be used on a log before it reaches its destination. If the mill is located in or near the forest area, they may go directly to the mill. In northern United States and Canada, logs are transported by sleds. Two-sleds or bobsleds are drawn by horses and may carry several thousand feet of lumber at one load. Roads built during summer months are used after snow falls. Sled tanks are sometimes needed to haul water and sprinkle the roads so that they will freeze slick and firm. Large, steam-powered tractors once drew trains of log sleds along snow roads. Gas motors have largely replaced steam, and small tractors are sometimes employed in sledding. Occasionally log chutes are made on which logs are slid from mountain sides down to valley roads. These are made by spiking two small logs side by side to form long chutes so that a log will lie between the two poles and slide down the incline on them. Grease is put on the slide so that the logs will run easily. On steep slopes, the poles are roughened to prevent the moving logs from developing too much speed and jumping from the incline. Horses or mules are sometimes used to snake turns of logs along slides not built on inclines. Hauling logs by wagon requires better roads than sledding. Wagons are used principally in the South and East. Log bunks are installed on the chassis, and special equipment for booming (tying the log on the wagon) is necessary when hauling over rough trails. Wagons with low wheels and wide tires are best suited to logging. Wide tires prevent miring of wheels on marshy ground. Logs may be loaded from a skidway or from level ground by cross-hauling. In cross-hauling the wagon is placed parallel to the log about 15 feet away. A chain attached to the center of the wagon is passed down to and around the log and back across the wagon. A team pulling on the opposite side of the wagon can roll the log up skid poles to the bunks. The day of long hauls by wagon has practically passed. Just as tractors have replaced slow oxen in yarding heavy logs, so motor trucks have been substituted for wagon and team in main hauls. Roads suitable for wagon hauls can be made fit for truck transportation with little additional labor. Stands of timber which once would have required railroads and spurs can now be logged and moved by truck. Small operators in the South with two or three trucks may haul logs to a portable mill. Large operators in Oregon may use a fleet of 20 trucks, motor yarders and donkeys, three or four tractors, and a pair of motor log loaders. Heavy trailer-type trucks can handle loads of 3,000 to 5,000 board feet, operating over distances up to 75 miles. Tramways and railroad spurs are sometimes constructed for short-distance transportation. The old wooden-rail tramroad is practically out of use. Crude tram tracks were made with poles for rails. It was not necessary to gage the track carefully as the car wheels could play slightly in and out on their axles. The cars were usually horse drawn, and the system was fairly efficient considering its cost. Narrow- or standard-gage railroads are also used with steam or gasoline motors to draw log trains. On large operations, using locomotives for transportation, spurs are built into parts of the woods where logs can be concentrated. Internal-combustion motors are being used in locomotives, and Diesel engines are also coming into use. Gas and Diesel motors simplify fuel problems and reduce fire hazards. Steam and motor loaders are used with rail-logging operations. Cars may be loaded or unloaded at any point with loaders carried on a railway car or built on endless chain tracks like the caterpillar type tractor.

TRANSPORTATION BY WATER Transportation by water is as old as the logging industry. The log drives of the North and the rafting in the Mississippi basin are epical and historical in their interest, Novels, stories, and songs center around the activities of "running" logs. In the North, the drive method is still used extensively, especially for pulp logs. DRIVING The logs are collected at landings by methods already described. If the streams are high enough, the logs are dumped into the streams and floated down to mills, or perhaps to railroads. If the streams are small, drivers must wait until freshets raise the streams enough to float logs. On small streams, dams with flood gates may be constructed. The gates are closed, water is collected, and the gates are then opened to make a "head" of water. Drives may then be made when desired. If more than one company is operating on one stream, each operator must mark or brand his logs before driving. Booms, which collect the floating logs, are built in the streams at the log terminal and the logs caught and identified.

RAFTING Rafting is done on larger streams where there are no falls. Logs are fastened together by "tie poles" running from one end of the raft to the other. On larger streams, logs may be "cradled" in binding chains and floated down to mills. In the early logging days, shanties were sometimes built on the rafts for the comfort of the loggers. Weeks were sometimes required to float the rafts down to markets. Some timbermen took their saddle horses along on their rafts and rode them back from the distant milling centers. Steamboats and tugs tow rafts on the larger streams or along the Northwest coast. Three methods of river transportation may be practiced by one logger. He may run his logs down a tributary stream in drives. At the mouth of the stream he may catch his logs and raft them into small units and float them to a larger stream or to navigable water. There he may combine his small rafts by lashing them into a large one, and have them propelled by a tugboat to their destination. FLUMES For shorter runs by water, flumes were once used extensively. Flumes are continuous troughs of water in which timber is floated. Although they are still used to a considerable extent, they are gradually disappearing. One flume 55 miles long is in existence in California. Flumes are best adapted for movement of small material such as may be used for pulp and mine timbers. These flumes lead along mountain sides, cross hollows and ravines on trestles, and require skillful engineering in construction. They must be built so that a definite water level may be maintained in the troughs at all times throughout their whole length, and the elevation must be such that the water will flow swiftly. Much water of course leaks from the flumeway, and from time to time headwater must be built up by diverting adjacent streams into the flume. |

Log Chutes.

Motor Logging. The motor truck is a modern means of transportation.

Wagon Hauling.

Railroad Transportation. Spur Tracks.

Logs are driven to the mill in flood seasons. Running Logs.

Aquatic Equestrians. Three-way Water Transportation. "Fluming."

| |

|

STORING LOGS In logging seasons, trees and logs are usually cut faster than mills can saw them. Consequently the logs must be stored by large mills which operate steadily. Logs may be stored at the mill by piling them in the yard or by keeping them in ponds or boom pockets along streams. Storage ponds serve a number of purposes: (a) Logs stored in them may be moved easily. Pond men, skilled in the use of long pike poles, can manipulate selected logs to the chain drags which convey the logs into the mill. (b) Water storage keeps the logs moist and prevents checking and cracking. (c) Bark beetles and other destructive insects cannot breed in submerged logs. (d) Water loosens gravel and stones which the logs have picked up when being dragged through the woods, and which would injure the saws if left imbedded in the wood. |

Water Storage.

| |

|

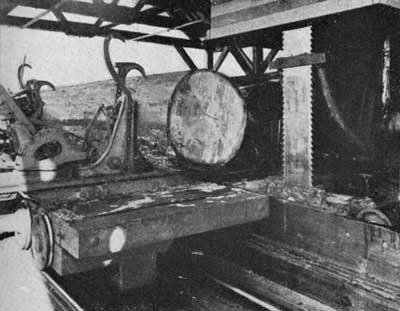

MILLING From the yard or storage pond the logs are carried into the mill either by an endless chain, fitted with teeth or drags to hold the logs, or by derricks. Tractors and cables, or winches, are used in some mills. The logs are scaled at the entrance and rolled to the log deck. From the deck they are rolled on the carriage, which carries them to and against the saw. TYPES OF SAWS Saws may be circular or they may be band type. The circular saw has the teeth on the circumference of a steel disk and turns like a wheel on its axle. The band saw is a steel belt with teeth cut on the edge. It runs at high speed over two pulleys. Some of the band saws have teeth on both edges so that the log may be driven against the saw from either side. Thus the speed of sawing can be almost doubled. In mills demanding high production, gang saws may be used. Gang saws consist of two or more saws mounted together. Instead of sawing one board at a time gang saws will cut as many boards as there are saws. SAWING The efficiency of a mill depends largely upon the sawyer. Since he controls the carriage and the log, the quantity and quality of lumber cut from the log depends largely upon his skill. A mechanical device called a "steam nigger," controlled by the sawyer, adjusts the log on the carriage so that it will produce the maximum a mount of clear lumber.

After the boards are ripped from the log, they fall on live rolls which convey them to edgers. These are small saws adjustable to different widths. They cut the bark and rough edges from the boards, which are then cut to proper lengths by trimming saws. Sawdust, slabs, and edgings are usually carried by conveyors to the boiler room where they are used for fuel. SEASONING Lumber is stacked in the open to season. Narrow strips of wood are placed between each layer of boards so that the air may circulate freely around them. Timber requires from 3 months to a year to season, depending on climate, weather, and its condition when sawed. Seasoning may be hastened and accomplished more efficiently by kiln drying. In this process lumber is loaded on small cars and taken into kilns where it is held at the desired condition of air temperature and dryness until thoroughly dry. Kiln-dry lumber is stored in buildings to keep it from absorbing moisture again. PORTABLE MILLS Where small, portable mills are used, there is no storing problem. Logs are collected and put directly on the deck. Three or four men make up the sawmill crew. Instead of transporting logs long distances to the mill, the mill is taken to the timber. Single circular saws are used principally. Gas or kerosene tractors are becoming popular for power because the tractor can be used to move the mill from one location to another as well as to drive the saw. |

Fore-and-aft hand saws increase sawmill production.

Portable Rigs.

| |

|

SUMMARY Lumbering is divided into logging and milling processes, but forestry is not closely related to milling. The history of lumbering is interesting from the social as well as the commercial viewpoint. The establishment of logging centers from New England southward, then west to the Lake States helped to build up the manufacturing centers of the Northeast. Next the southern pines were cut to fill market needs. Lack of sufficient lumber in the East and development of better transportation facilities sent the lumbering center across the Western States to the redwood, ponderosa pine, and Douglas fir stands of the West coast. Logging is divided into the following operations: Marking, measuring, felling, trimming, bucking, skidding or collecting, and transporting to the mill. Regardless of machinery designed for felling and bucking, these jobs are still largely done by hand. In felling, care should be taken to protect the workman from being injured, to protect growing timber from damage by the falling trees, and to protect the tree being cut from breaking or splitting. Limbs should be trimmed to make smooth logs which are easier to handle than knotty ones. Bucking is another word for log making. Tree trunks are cut into log lengths by use of two-man cross-cut saws, or in the big timber of the West coast by one-man cross-cuts. Logs are hauled in many ways. Skidding, or collecting logs on skidways, landings, or yards may be done by snaking, using yarding sleds or carts, tractor yarding, or line skidding. Logs may be dragged along the ground by low-lines or carried through the air on high-lines. Sometimes chutes or slides made of poles are used for skidding logs. Logs may be transported from skidways or yards to mills by many forms of conveyances. Sleds drawn by horses or by tractors can carry great loads when there is sufficient snow. Wagons may be used for short hauls. Modern motor trucks are replacing sleds and wagons in hauling on main roads, Trucks have brought formerly inaccessible quantities of timber into markets. Huge loads may be transported over distances up to 50 or 75 miles. Water transportation is not used so much as formerly because stands of timber have receded from water courses, and roads have been built to many of these areas. Logs may be driven in small streams, or in larger streams, rafted and floated to markets. Steamboats may propel rafts on sluggish streams and larger rivers. Flumeways are sometimes used to float logs or small timber to mills. Tram roads with wooden or steel rails are used for transportation. Narrow-gage or standard-gage railroads are sometimes built into timber stands, but only large operators use locomotives for traction. Motor trucks are replacing railroad logging also. Logs are stored, when possible, in water. They are handled and preserved better in ponds than in dry storage. Logs are sawed in large mills by band saws, and trimmed and edged by highly mechanized processes. Seasoning is done in open air or in kilns. Kiln-dried lumber is preferred to open-seasoned lumber.

Portable mills play an important part in the lumbering business. Small stands, which could not otherwise be utilized, can be economically cut by the small mill. The saw rig that can be hauled from one location to another by a tractor and then driven by the tractor is a very useful unit in the lumbering business. |

Sawing. Seasong, see pp. 197, 198.

|

| <<< Previous | <<< Contents>>> | Next >>> |

|

ccc-forestry/chap9.htm Last Updated: 02-Apr-2009 |