|

History of Tahoe National Forest: 1840-1940 A Cultural Resources Overview History |

|

CHAPTER IV

Era of Development and Diversification, 1859-1906

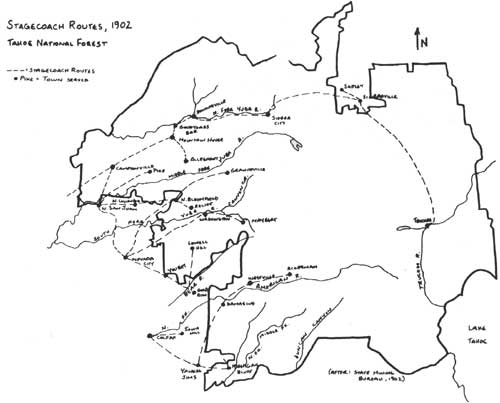

During the years between the discovery of silver and gold in the Washoe in 1859 and the establishment of Tahoe National Forest in 1906, the economic activities begun in 1849 changed in their scale and focus. New mining technologies, coupled with refinements of systems invented before 1859 and the influx of outside capital for financing changed gold mining from the nascent industrial form that had been established earlier, to a modern industrial system dependent on technical skills, scientific knowledge and processes, and a permanent, trained work force. In drift, hydraulic, and quartz mining such development altered the mining system forever.

The entry of outside (i.e. San Francisco, New York, or London) capital contributed to the development of other industries in the Forest. Initially investing only in mining, capitalists now poured their money into logging, transportation and water development. Each had reached a plateau by 1859, and thereafter was primarily advanced by the entry of new sources of money to aid further development. While large scale capital did not directly effect agriculture, the new markets for agricultural goods in the Washoe, and those opened by the Central Pacific Railroad, led to greater agricultural development within the Forest. Increased agricultural production required more intensive use of resources, and led to the system of irrigation and grazing on the public domain present today.

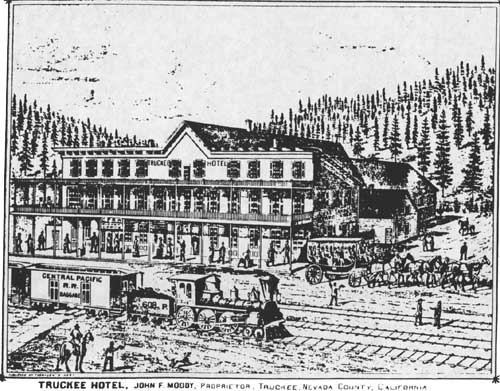

The period of development and diversification of industry and economic activity on the Forest also affected community development. As we have seen, the early transitory mining camps that sprang up in the early years of the gold rush were replaced by more permanent towns based on deep deposits or favorable locations. Industrial mining after 1859 continued this process. In addition, new communities developed independent of direct ties to mining. Settlements identified with railroad stations, logging and lumber industries, and agriculture expanded during these years. There was greater stability in population. The periodic "rushes" and mining excitements, with a few exceptions, ceased, and the great population fluctuations associated with the gold rush decade were tempered. As mining and other communities became more "family" oriented, a higher percentage of women and children were present than in the earlier settlements.

|

|

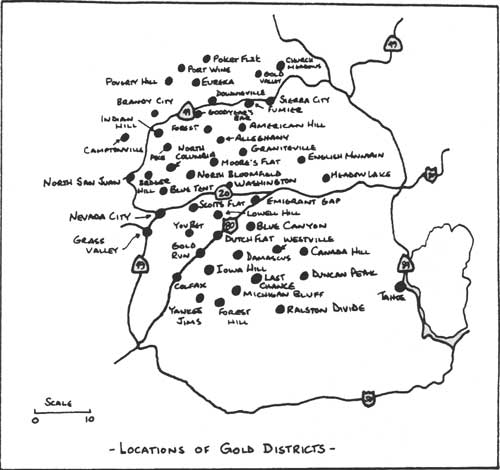

LOCATION OF GOLD DISTRICTS (click on image for a PDF version) |

The Mining Industry on the Forest.

Mining for gold and other minerals on Tahoe National Forest during 1859-1906 was largely carried on in the areas developed during the first decade of the gold rush period. For example, mines in Alleghany and Michigan Bluff, located in the early 1850s, remained active throughout this period. Some locations, uneconomical in the early years, became valuable producers after new technologies aided access to gold deposits (MacBoyle 1918: 5). Mining methods depended on the type of gold deposits mined — placer gravels or quartz lodes — and production was affected by technological advances such as the introduction of practical electrical power in mining and milling (State Minerologist 1894: 413). Knowledge gained in the deep Comstock Lode mines proved valuable as California miners tunneled to greater depths. "Once back in California, the former Comstockers quickly demonstrated the necessity for sinking shafts to greater depths than Californians had believed financially feasible, and when they proved their point on that score, they automatically forced Californians to give attention to methods of underground ventilating, to adopting better hoisting equipment, and to replacing hemp rope with steel or iron cables" (Paul 1947: 289-290). Shafts formerly 100 to 200 feet deep were dug and blasted to below 1,000 feet (IBID: 290). New methods allowed for continued development of mines like those at Sierra Buttes, discovered in 1850, well into the twentieth century (Sinnott 1976: 217). The new methods also prompted rushes to areas hitherto untouched, like the Meadow Lake and Squaw Valley areas, in the 1860s (Fatout 1969: 25; Gudde 1960: 74, 108, 188, 237, 345). The development of more sophisticated hydraulic mining methods also led to the development of gravel mines at North Bloomfield, and in the Washington vicinity during the 1860s (MacBoyle 1918: 99-105). Hydraulic mines were scattered on the forest wherever there were deposits that could be worked by this method and water was available (Clark 1970: passim). Drift mining, discovered and used before hydraulicking began, regained a prominent place in mining industry, especially after the end of widespread hydraulic mining in 1884 (Vivian 1890: 427).

A change in the organizational structure of gold mining was necessary in order that gold mines could develop industrially. As we have seen, miners banded together as technological improvements altered mining methods. The gradual result was the employment of hired miners on claims. This practice started largely with river bed mines, worked at first as cooperatives and later with miners as employees. Miners also cooperated to dig mining water ditches. This business later became, like mining, industrialized. Financing shifted from the miners to local businessmen and finally to capitalists from outside the mining region. This fact had its effect on mining communities. The Nevada City Gazette noted in May 1869 that

Grass Valley lives not off the mines, but the miners — an important distinction. The wealth of the mines all goes to San Francisco. The wages of the miners are spent here . . . (quoted in Lingenfelter 1974: 87)

The investment of large sums of outside capital required claims large enough to ensure a profitable return. As rules were gradually changed in the 1850s to allow larger claims such investments became more practical. By 1872, the United States Mining Law allowed placer claims of twenty acres per person, or 160 acres for a single association of at least eight (Pagenhart 1969: 109-110). Similar changes were made in quartz mining law assuring capitalists that their claims would enjoy legal protection sufficient to allow for safe investment (Paul 1947: 226-227; 237-238). For consolidation of claims and codification of mining law resulted in economies of scale and made potential investors more willing to risk their money (Pagenhart 1969: 110).

During the last four decades of the nineteenth century, most of the major mines on the Forest were operated by miners using investment capital from outside the gold region. The Malakoff Mine at North Bloomfield, for example, was organized in 1865 by Jules Poquillion, and by 1866 was established as the North Bloomfield Gravel Mining Company under the leadership of Lester L. Robinson and a group of San Francisco businessmen. Within eight years there were thirty shareholders with $3.5 million invested in the mine (California Department of Parks and Recreation 1979: 14). A similar situation prevailed at the Bald Mountain Drift Mine at Forest City. Located at first by a group of miners who tried and failed to mine it cooperatively, it eventually fell into the hands of M. Redding. By 1869, new stock was issued, tunnels were dug and the mine became quite profitable (Fariss and Smith 1882: 478-9). Mining shares were sold in San Francisco, Stockton and Sacramento in the early 1860s; very rapidly thereafter "Easterners and Europeans . . . began sending their capital to the Pacific Cost for investment" (Paul 1947: 183-4). In fact, the need for capital in California and Nevada was such that by the mid-1860s, a major change in California banking practice was necessary to make them able to meet the heavy demands put on them by mining. Money from British sources began to arrive and the banks became eventually of great significance as channels through which foreign funds were directed into Pacific Coast investments (Paul 1947: 184-186).

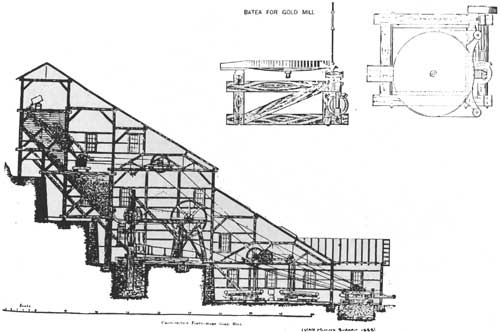

The mining and milling of gold bearing quartz required deep tunnels, heavy machinery a transportation network, stamp mills to crush the ore and a reduction plant to process the gold itself. Large numbers of miners were needed to work deep mines, and skilled engineers and chemists to design the mines, equipment, and process the ore (Wiltsee 1931: 4; Spence 1970: 79, 144). The Mining and Scientific Press (11/21/1903: 332) noted this change in 1903 in an article entitled "Advantages of Technical Education."

Within the past twenty years this old-time practical miner has been slowly forced into the background and in his place is found the technically educated man, who with a worldwide knowledge of his business is equal to almost any emergency . . . The western U. S., Australia and South Africa have furnished a practical school, where unusual conditions were found and had to be met — novel situations in mine and mill. The old-timer would have undertaken these varied problems in the old time manner and he would have failed, or at best would have made but a moderate success.

Similar technical skills were needed in the development of deep drift mines, as many of the same problems were met as in quartz mining. Hydraulic mines, while not always as technically complicated in an engineering sense, required vast capital outlays for construction of adequate water systems (Kelley 1959: 34-41 passim). Water companies developed parallel to hydraulic mining as some miners got out of mining and went into water instead (Pagenhart 1969: 85-88). The South Yuba Canal Company is an example of such a company.

After 1859 emphasis was placed on drift, hydraulic, and quartz mining. To be sure, other methods of mining still went on; as late as 1880 Chinese miners still mined river beds and reworked mine tailings (Public Lands Commission 1880: 17). Other groups or individuals were still prospecting or working small claims, but the bulk of production was in the large industrial placer and quartz lode mines.

Drift mines represented one of the largest producers of gold, mostly because this form of mining, like quartz lode mining, survived longer than did hydraulicking. As mentioned earlier, drift miners initially followed the Tertiary Gravels into the hillside and mined the deposits in a manner similar to quartz mining. Gold bearing gravels were shoveled into hand cars, removed from the mine and washed in long sluice systems. When the gravel was compacted into cement, stamp mills were employed to crush it (Vivian 1890: 428). Drift mines, with their long tunnels, used large amounts of timber. At the Bald Mountain Mine at Forest City, "enormous quantities of heavy timber are required in the tunnels to support the vast masses of loose gravel above" (Fariss and Smith 1882: 479). Hand cars, mule cars and small locomotives pulled ore out of the mines. The Hidden Treasure Mine, near El Dorado Canyon in Placer County, replaced its mule cars with a locomotive from Philadelphia in 1882 (Thompson and West 1882: 220). The Paragon Mine, owned by Abraham Breece and Judson Wheeler, near Bath in Placer County, had a tunnel into the gravel deposit three quarters of a mile long; the Mountain Gate Mine at Damascus "struck the blue gravel after running a tunnel of seven thousand feet" under a volcanic cap. Hand and mule cars carried the ore from the mines. Some of these mines employed a few men; the Paragon, despite grossing $13,000 per month in the 1880s had a small crew (IBID: 219, 230-231). Most of the more productive mines had much larger operations. The Bald Mountain Mine supported a town of 800 (Public Lands Commission 1880: 17). The Bald Mountain Mine was described in 1882:

The main tunnel is now a mile and three-quarters into Bald Mountain, at one place being thirteen hundred feet below the surface. Side tunnels from one hundred and fifty to five hundred feet in length extend on either side, at an average of eighty feet apart, of which there about two hundred and fifty, the intervening gravel of the channel being excavated as they proceed. The limit of the claim will be reached at a distance of two miles from the mouth, and the coming summer will see its completion, when all the pay gravel will be cleaned up, and the pillars taken out. Tracks are laid in all the tunnels being worked, over which an engine, christened 'H. K. Wallis' in honor of the superintendent, makes hourly trips both day and night, carrying cars to and fro in the long interminable corridors. The main tunnel has a total raise of 207 feet from the mouth inward to the locomotive station, as it follows the course of the channel, creating a perfect system of drainage. Four hundred and forty-one acres of mining ground are owned by the company, four miles of creek, two flumes of a half a mile each, a mile and a quarter of washing flume, and at the bottom of the latter flume tailing claims 8,000 feet in length. Two dumping yards, double-planked, with a capacity of 25,000 cubic yards each, receive during the summer, when water is scarce, the gravel to be washed . . . At present the number of men on the payroll of the company is 140, the number having reached as high as 230. Nearly all the gold found in the great blue lead is very coarse, the largest piece ever taken from this mine weighing over seventy-five ounces. The yield of the mine for the last ten years has been about $2,000,000, of which $795,000 were paid in dividends. (Fariss and Smith 1882: 478-9)

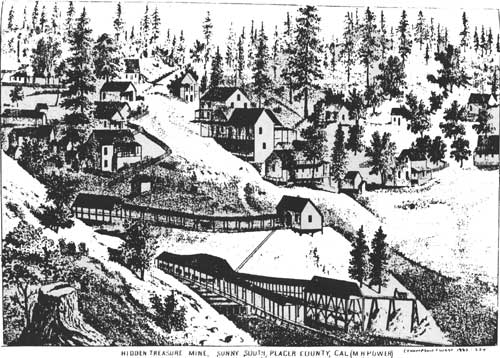

Of course, drift mines were not usually as large or productive as the Bald Mountain. Other drift mines of such size included the Hidden Treasure (or "Sunny South") northeast of Michigan Bluff, employing seventy men in 1882, with a "school house, two hotels, and two stores, and numerous cozy and well-furnished family cottages" located nearby. The mine produced $114,168 in 1880 (Thompson and West 1882: 220, 388). By 1890, the mine had a crew of 135, whites and Chinese, as well as 1,000 feet of sluices and an 8,000 foot tunnel (Vivian 1890: 430). The Mountain Gate at Damascus was worked by about twenty miners but supported a community of 150 that boasted a school with "about twenty-five scholars," plus cottages with gardens, a store and a "large hotel." The mine yielded $1,000,000 between 1860 and 1882 (Thompson and West 1882: 378). Drift mines were also located around Downieville the Duncan Peak district in eastern Placer County near the Greek Store Station, at Damascus, and in Nevada County in the Relief Hill, Grizzly Hill, Graniteville and Lowell Hill districts (Clark 1970: 44, 43; MacBoyle 1918: 92, 94-96, 99, 11, 30-31). Valuable drift mines were also found on an ancient channel running from Minnesota, Chipps Flat and Alleghany through Monte Cristo and on into Plumas County, as well as in the Slate Creek region in Sierra County and above the Bear River at Liberty Hill (State Minerologist 1882: appendix 174). The North Bloomfield and Derbec drift gravel mines in 1888 employed twenty-five and one hundred men, respectively, and were among the largest in Nevada County (State Minerologist 1888: 454-458). Other drift mines were located near hydraulic mines and references often combine them under the heading of "placer" mines, making it difficult to know which mines used the drift method (Clark 1970: passim).

|

| HIDDEN TREASURE MINE, SUNNY SOUTH PLACER COUNTY, CAL. (M H POWER) (Thompson & West 1882: 224) |

Drifting, in 1890,

. . . is of most importance now in Placer, Nevada and Sierra Counties. It is a revival, having been pursued to a considerable extent early in the history of the State, and then abandoned for the hydraulic style . . . (it is now the) most safe and certain branch of the business extant. (Vivian 1890: 427)

The report noted that while some mines employed 100 to 200 men, most were worked by ten to fifty. The Forest Hill Divide region was noted as being especially rich in drift mines.

The major drift mines were operated by mining companies for the benefit of stockholders (Fariss and Smith 1882: 478-9). The shares of stock were sold as far away as England; in 1882, the State Minerologist noted the failure of an English-owned drift mine at Whisky Diggings in Sierra County. Ironically the mine produced well after the disappointed English investors pulled out (State Minerologist 1882: appendix 180). Money invested paid for wages (in 1888, $2.50 to $3.00 a day in most mines) as well as equipment, including water wheels for compressed air, hoists, cars, drills, stamps, pumps, boilers, sluices and mills (State Minerologist 1888: 454-475 passim).

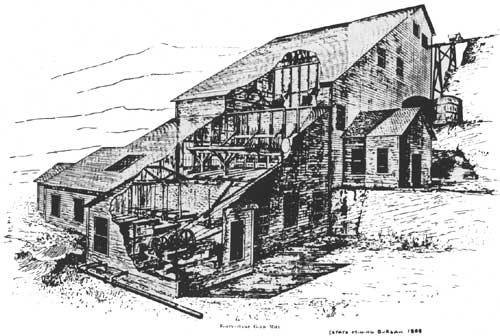

Quartz mining was also a productive form of mining undertaken on the Forest; however, it was also the most technically difficult in terms of mining and milling the gold ores. Quartz mines operated by digging into a quartz vein, aided by drills and blasting powder, and shoring up the tunnels and shafts as mining proceeded. Ore was removed by hand or mule cars, and processed in stamp mills where the gold would be freed from the surrounding native rock. California miners made improvements on early mill designs and produced the California Stamp in 1851. Such mills replaced the animal-powered arrastres and Chili mills that had been used earlier. Improvements in mills over the years gradually made the more dependable and effective at crushing ore, and methods for automatically feeding ore into the stamp mill were developed. While early machines were wasteful (as much as sixty to eighty percent of the gold was lost in the early years), improvements in refining led to a greater percentage being saved. The chlorination process introduced in 1858 and largely perfected in 1860 solved the problem of separating gold from sulphide ore, something mercury had been unable to do (Paul 1947: 135-142). The combination of better milling and refining methods and the exhaustion of placer gold in many areas had made quartz lode mining attractive in the late 1850s, especially as there were "untouched quartz veins" in the foothills. Miners knew that "the history of other parts of the world had shown that a good vein would last for a greater number of years than any other type of deposit" (IBID: 143).

Quartz deposits were found as high as the Sierra Buttes and as low as Auburn. Within the Forest quartz mines were located largely on the western side of the Sierra Nevada, with the exception of small mining activity around Sierra and Squaw valleys (Sinnott 1976: 129; Gudde 1960: 237, 345). Quartz lodes were discovered in Humbug Canyon in Placer County by James Lynn and others in 1853; however, as noted, mining in the quartz deposits throughout the Forest reached its peak after 1859 (Thompson and West 1882: 217-218).

The mine manager was expected to be familiar with all phases of the mine operations.

Basically, his task was to take charge of a property, direct exploration and development, and make provision for the extracting, processing, and even sale of its ore. In finding and extracting ore, he had to have some knowledge of geology, minerology and surveying. Extracting required knowledge of tunneling, drifting, and shafting. He had to be skilled in mechanical engineering to plan for installation and use of hoisting, ventilating, or draining equipment, and an underground transportation system. Chemical and metallurgical skills were necessary to supervise ore treatment . . . (he) must understand milling, reducing or smelting machinery. A manager also frequently had to assume the role of civil engineer to build roads, tramways or flumes. He was a business manager . . . and supervisor of a large work force and responsible to his employer or corporation board. (Spence 1970: 144)

Large mines had a compliment of subordinates, including mill and mine superintendents. Deep complicated mines often had assistant superintendents at each level, as well as shift bosses, mechanics, and others. A shift-manager's success was determined by the efficiency of production. Labor costs often represented sixty to seventy percent of underground expenses. By the 1870s U. S. universities were beginning to graduate mining engineers, who over time became influential within the mining industry. Many became managers of mines, technical consultants to owners, investors and promoters, or expert witnesses in litigation (IBID: 79, 144, 168).

|

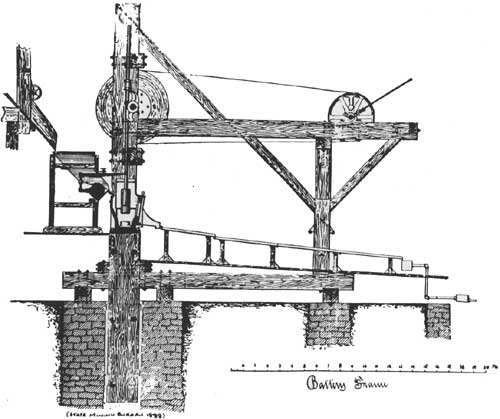

| FORTY-STAMP GOLD MILL (State Mining Bureau 1888) |

|

| CROSS-SECTION FORTY-STAMP GOLD MILL (State Mining Bureau 1888) |

|

| (State Mining Bureau 1888) |

Deep mines also required a skilled work force. California's quartz mines were manned by miners who had become experienced in mining elsewhere. Some had worked in the Nevada mines; others came from areas in the U. S. or Europe where mining had been practiced for many years. Among the most famous group of deep miners were the Cornish. Some had arrived early in the gold rush, but "their regular introduction into mining proper was a subsequent phase: they came in continuously after the original impulse of the gold-rush had ended in the mid-fifties, and thousands — miners and non-miners — had left with their takings, or without. Those who came in were professional miners . . ." (Rowse 1969: 257). Some mined briefly before opening other businesses or ranching; others stayed in mining. "Samuel Blight (who came to Grass Valley at eighteen) after many years of both quartz and hydraulic mining became captain of various mines in the district" (IBID: 262). John Tamblyn combined a variety of careers. He arrived in California in 1864, became foreman of a mine in the Owens Valley, and then traveled to Sierra City where be built a chlorination plant. He raised fruit on a small ranch, and in 1875 became a Methodist minister whose circuit included "the mountainous counties of the state" (IBID: 259). The Cornish became especially important in the mines around Grass Valley and Nevada City, where by 1861 most of the mining was done by the Cornish (Paul 1947: 323). Cornish miners later formed the first miners' unions in the area in 1869, largely over the issue of the use of one-man drills and dynamite, which the miners said were unsafe (Rowe 1974: 120-124).

By the 1860s most of the necessary preconditions for the development of deep quartz mines had fallen into place. Refining processes allowed more efficient recovery of gold ore, experienced miners and managers were available, and capitalists began to invest in the mines as confidence in them recovered from the damage done in the 1850s (Paul 1947: 300-302). This renewed interest stimulated the quartz mining industry and expanded production but it did not insure success. Some areas developed deep, long-lasting productive mines that operated well into the 1900s; others were prospected, mined, and gradually abandoned; still others were prospected, mined, and produced spectacular failure.

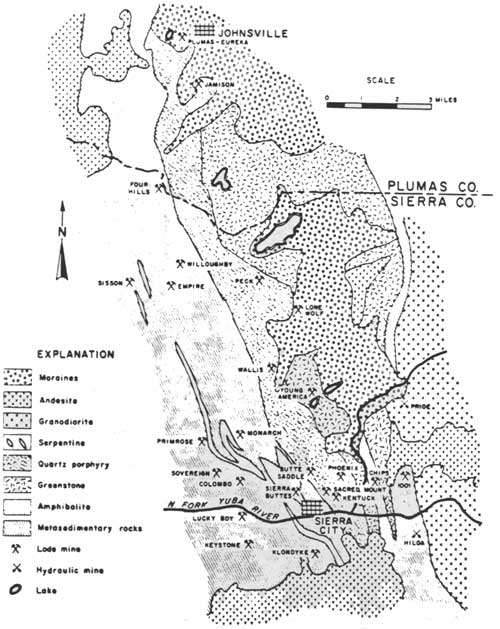

One of the most famous of California's deep quartz mines was the Sierra Buttes Mine near Sierra City. The ledge was located by Italian miners in 1850, and was worked through the rest of the century. The Reis Brothers soon bought out the original owners. In 1864, they built a seven mile ditch around the Buttes to the mine at a cost of $20,000. The Reis family sold the mine in 1870 for $1,000,000 to a London-based group who called themselves the "Sierra Buttes Gold Mining Company" (Fariss and Smith 1882: 481). A developer of many other Sierra mines, the company had substantial capital investments and experience in California mining. It operated the Sierra Buttes mines for the rest of the century and made significant improvements in its operations (Jackson 1968: 141). In 1870, the mine had five tunnels. By 1882, four more were dug, as the original five were played out. In 1882, the mine's three mills had ninety-six stamps in operation. A snowslide in March, 1882, destroyed a thirty-stamp mill worth $40,000, with its water-powered turbine wheel power plant. The accident caused twenty men to lose their jobs and the monthly tonnage of ore crushed dropped from 5,600 to 300 tons. Nevertheless, the company was able to overcome this adversity (Farris and Smith 1882: 481). In 1888, the State Minerologist noted that the company had built nine miles of road to the mine to transport "ores, timbers, fuel, etc." Besides the stamp mills, "there are several arrastres in operation here . . . working on a lot of old tailings and not of recent production" (State Minerologist 1888: 573-74). The entire establishment was illuminated with incandescent electric lights powered by water turbine wheels. The mine employed 209 men at an average wage of $50.00 per month with board (IBID: 576-7). The company provided boardinghouses or cottages to house the workers near the mine (Farris and Smith 1882: 481).

|

| GEOLOGIC MAP OF SIERRA CITY AND JOHNSVILLE DISTRICTS, SIERRA AND PLUMAS COUNTIES. After Turner, Downieville folio, 1897. (Clark 1970: 116) |

Other large quartz mines in Sierra County were noted in the Minerologist's report in 1888, including the Young America near Sierra City; the Rainbow and Eagle mines at Chipps Flat; the Myrtle and Gold Bluff mines near Downieville; the Buffalo in the Hog Canyon District; and the Rising Sun Mine in the Alleghany District (State Minerologist 1888: 478-580).

The Sixteen-to-One Mine at Alleghany in Sierra County was another of the important quartz mines of the period, and produced from 1896 through 1965, which made it the last major gold mine to close in the state. It produced an estimated $35 million during this time. In fact, the Sixteen-to-One was a consolidation of a large number of smaller mines and claims, including the Ophir, Rainbow, Rainbow Extension, Red Star, South Fork, Tightner, and Twenty-One. The Sixteen-to-One was named in "honor of the silver-gold ratio of U. S. coinage, as proposed by William Jennings Bryan in his campaign speeches" (Clark and Fuller 1981: 54-55). The activity around the Sixteen-to-One increased after 1890, and especially after the main claim was located in 1896. The mine was expanded through the rest of the century, and by 1907 the mine, and its consolidations, was known for the richness of its ore. Henderson L. Johnson, a former teacher and miner in Colorado and New Mexico, was the driving force behind the mine (IBID: 55). Much of the mine's later development came after the establishment of Tahoe National Forest.

There were a large number of important quartz mines within Nevada County, many of which were clustered around Grass Valley and Nevada City. Within the Forest, quartz mines were located in the Washington, Canyon Creek, Meadow Lake and Eureka districts. Mines in the Washington District included the Yuba, three miles above Washington; the Blue Bell, near Ormonde at the mouth of Canyon Creek; the Grafton and Eagle Bird, near the Blue Bell; the Washington Mine at Ormonde; the Champion at Maybert on the South Fork of the Yuba; and the Spanish Mine three miles north of the town of Washington (State Minerologist 1888: 435-442). The Spanish Mine was located in 1883 and the company formed in 1884 after consolidation of ten mining claims. By 1888, the mine had a tunnel 1,200 feet long, as well as other smaller tunnels. "The mine employs, besides a foreman, two white men and eight Chinamen, who extract about four thousand tons of ore per month, enough to keep the mill steadily occupied." Cars were hauled into the mountain by mules and traveled out by force of gravity. The mill employed six men; as was customary, the Chinese wages were about one-half that of the white miners (IBID: 442-444).

In the Eureka District, the major mine was the Gaston Ridge Mine, four miles south of Graniteville. The mine employed thirty miners and six mill hands. The mill was powered by a steam engine, its wood fuel delivered to the mine "by floating in the North Bloomfield Ditch." Workers were paid $3.00 per day (IBID: 448-450). Other mines in the district included the Rocky Glen, one and one half miles south of Graniteville, and the Gambrinus and Baltic Mines near Eureka.

The Canyon Creek District, running between the mouth of Canyon Creek and Bowman Dam, had three mines, the Chase Claim, Blue Jay and Canyon Creek (IBID: 452-3).

Deep mines were also located in Placer County, although most were centered west of the boundaries of the forest, in the area around Auburn and Colfax. The Sterrett Mine on Sailor Canyon was "on an immense lode of gold bearing quartz" (Thompson and West 1882: 218). The mines within the Forest boundary in Placer County were mostly drift or hydraulic mines. In 1890, Nevada, Amador and Sierra counties were the top quartz mining counties in the state. Placer County was far down on the list.

|

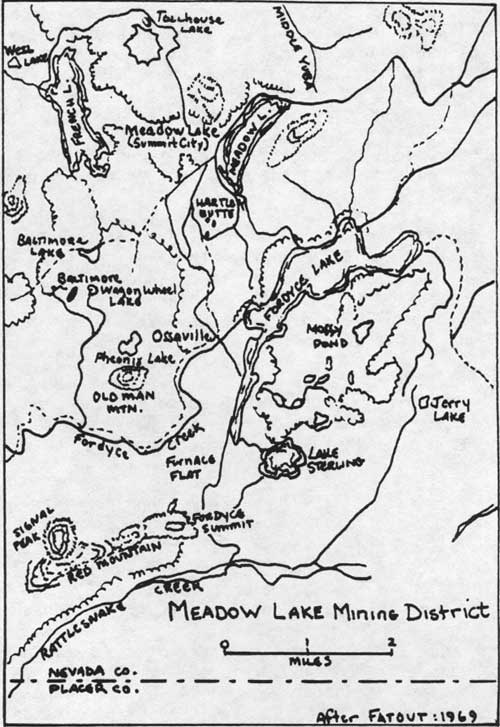

| MEADOW LAKE MINING DISTRICT (after Fatout: 1969) |

Of all of the Forest's mining districts, Meadow Lake has had perhaps the most varied history, demonstrating clearly the boom-bust cycle so familiar in mining. In the spring of 1864, news of a gold discovery at Meadow Lake caused a rush to the area. Gold was found as "thin flakes of free gold in the spongy decomposed rock on the surface" and in ledges two to eight feet thick. Unfortunately, the area was rugged and exposed. It was located on the crest of the Sierra Nevada at an elevation of 7,000 feet and was forty miles distant from Nevada City in a relatively inaccessible area between the Henness Pass and Dutch Flat routes to the Washoe Valley (Fatout 1969: 25-28).

Henry H. Hartley, a former bookstore clerk turned hunter, trapper and prospector was the person who had discovered gold at Meadow Lake in 1863. Hartley, with two others, formed the Excelsior Company and staked off claims the following year. The California Company also made claims, calling them the California Knickerbocker, Indian Boy and Indian Queen. By June, 1865, machinery for four quartz mills was on the way to the lake. Within a month there were 250 men and twenty women in the camp. Businesses quickly sprang up to serve the settlement, including sawmills, an assay office, a pony express carrying mail and newspapers three times a week to Nevada City, several butcher shops, a hotel and two saloons. In late June, the town site of Summit City was laid out on the southwest side of the lake, with wide streets set at right angles and named A, B, C, and First, Second, Third, and so on, with blocks of uniform size. Shortly thereafter three other "towns" were laid out — Richport, Lakeville and Baltimore City. By mid-August newcomers were arriving at the rate of one hundred per day. A "corps of hurdy-gurdy girls" migrated from Downieville, and a daily stage line from Gold Hill was established. By late August, there were stores, restaurants, boarding houses, saloons, three hotels, a brewery, bookstore, cigar shop and real estate office (IBID: 31, 35-40). The Marysville Appeal noted on August 20, 1865, that "seventy-five houses have been erected, a hurdy-gurdy establishment is in full blast, and a number of gambling houses have opened, and other indications of civilization are becoming apparent."

The onset of winter weather reversed the flow of population, but with the next spring a boom larger than the first began. Eventually eight "towns" existed in the area. Optimistic Meadow Lake citizens opened a stock exchange, and a newspaper (the Morning Sun) began printing in June, 1866. Despite the activity, only 300 miners were at work, and a lot of "dead-work" — road building, setting up mills, and so on — was yet to be completed. The newspaper noted that to get the rich ledges would require the aid of capitalists. "Individual efforts may prospect, but companies, regularly organized must develop mines," cautioned the editor of the Morning Sun. Such development capital was not available, especially as miners began to return from the area describing it a "humbug" and "the biggest bilk in the world . . ." (Fatout 1969: 68-77, 84).

Early in 1869 only seven families "rattled around" the 300 or so empty houses. By June the population was only forty or fifty people. Between 1869 and 1893 sporadic mining and attempts to deal with the high sulphur content of the ore came to little. In 1893 the winter passed with no one in the city; Hartley died in 1892 of opium poisoning. By the 1940s no buildings were left at the site, only faint outlines of streets and the Plaza (IBID: 109, 140-46).

Meadow Lake as a mining district was a failure, and thus compares unfavorably with successful mining districts like Alleghany or Sierra Buttes. The district does however reflect the boom-and-bust pattern of mining in the West. The miners dreamed of great strikes, help from outside capitalists, or new processes to help them through the lean years; in the end there was only disappointment. The town was virtually a prisoner of winter weather, which forced many to leave. Mining continued in the face of low grade deposits, bad weather and isolation, but the lack of sufficiently valuable ores eventually caused the town to die like so many other mining camps and towns in the West built on hope or on less valuable deposits.

Hydraulic mining is the remaining significant gold mining technique used on Tahoe National Forest during the latter nineteenth century. More than any other kind of mining, hydraulicking has left permanent and massive scars on the landscape that remain visible today. All mining methods were to a greater or lesser extent environmentally destructive; hydraulicking was the most devastating of all. The process "eroded hills, wrecked roads, inundated buildings, clogged streams with debris, flooded grazing and agricultural land, and obliterated whole towns" (Fatout 1969: 23). Hydraulicking has left pits, debris fills, abandoned flumes and canals, tunnels, and dams on the Forest.

Hydraulic mining was developed early in the gold mining period. Between 1853 and 1868 the process underwent a period of experimentation during which many of the production problems were ironed out. Major innovations discussed earlier included the change from canvas hose to iron pipe to tolerate higher water pressures starting in 1853; improvements in stilling and measuring devices; more powerful nozzles, usually called "giants" or "monitors" able to direct the jets of water under extreme pressure; the use of explosives to break up cemented gravels; and improved sluicing systems (Pagenhart 1969: 101-104). By the later 1850s, hydraulicking was in wide use, wherever conditions allowed it. In 1858, a writer for the Alta California traveling through the northern mining districts witnessed hydraulic mining and tunneling operations that were "conducted on a gigantic scale." In western Sierra County, he observed "multifarious bank claims supplied with water from ditches and flumes which cross then recross the county in every direction . . . in fact the hills and flats are grid-ironed with long lines of boxes, conveying the indespensible element to the dry diggings" (White 1961: 84). Flumes and canal systems designed to provide water for long toms and sluices were unable to meet increased demand for water once hydraulicking began. It was a popular mining method, "so effective that from that day forward no other form of placer mining was attempted if hydraulicking were at all possible" (Pagenhart 1969: 101). Invented in California, hydraulic technologies rapidly expanded to other areas in the West. Charles Yale, in California Mines and Minerals in 1899, stated that "it may be considered exclusively the product of California" (quoted in Pagenhart 1969: 101).

The years 1859 through 1864 were depression years in the hydraulic mines of the Yuba-Bear basins because of "desertions" to the Fraser River and Comstock mining areas. In Nevada County only North Bloomfield and Omega mines were active because they were adequately supplied with water — North Bloomfield with water from the Irwin Ditch of the Eureka Lake Company, and Omega from a branch of the South Yuba Canal Company ditch (IBID: 116). Draught also severely hindered all hydraulic operations between 1862 and 1864. However, after 1864, hydraulic miners found that both water and finance capital was available for expansion as the draught ended and the Comstock excitement generated renewed interest in mining investments (Kelley 1959: 33-34).

As hydraulic mining gained in popularity its debris and tailings began clogging up small creeks. Only those mines operating near major river channels could economically remove the mountains of debris. Thus, many small operators and those with unfavorable locations were forced out of business. Between 1867 and 1870 these problems were basically worked out, as new drills and dynamite eased construction of drainage tunnels to remove debris (IBID: 41-42). By 1870, W. A. Skidmore, a mining expert, could assert that "hydraulic mining has made such rapid strides on the road of progress, and assumed such monster proportions in the past year or two, that now the vast magnitude of its operations serves to almost totally eclipse every other branch of mining industry (IBID: 45).

|

|

NORTH BLOOMFIELD AREA ca. 1875 (after Pagenhart, 1969) (click on image for a PDF version) |

Hydraulicking required tremendous amounts of water. Water was sold by the "miner's inch," which varied in many areas at first, but became relatively standardized at about seventeen thousand gallons in twenty-four hours. The North Bloomfield Company's ditch system had a capacity of 3,200 miners inches, or 5,440,000 gallons per day (State Minerologist 1888: appendix 152, 161). In 1879, the North Bloomfield mine used over fifteen billion gallons of water (State Minerologist 1882: appendix 172). Other necessary resources included lumber for flumes, dams, and general construction; pipe and monitors; stamp mills to break up cemented gravels; sufficient sluicing to recover the gold; a system to remove the debris; a sufficient work force to operate the mine; and enough financial strength to get the mine started and operating smoothly before pay dirt was reached, as well as enough to enable the company to develop the necessary water transportation system. Interestingly, hydraulic mines and mining water companies were among the first to use electric lights and telephones as a part of their operations. "In 1878 the North Bloomfield, the Milton, and the Eureka Ditch Company built the first long distance telephone line in the United States, stretching from French Corral up the San Juan Ridge to the various ditches and dams of the three companies in the high Sierra." The system cost $6,000 to build and had its main office in North San Juan. The line connected twenty-two stations, and was used to monitor flows and watch for breaks. It replaced an earlier telegraph system. By 1880, the company introduced large electrical lights enabling the miners to see as mining went on twenty-four hours a day if water was available. The electrical system used power generated by water wheels and was one of the first industrial uses of electric lights in the nation (Jackson 1967: 50-51).

Hydraulic mining was, in essence, a grand form of sluice mining. Water under great pressure washed overburden and pay dirt through debris removal systems and complicated sluicing arrangements. Every so often the sluice was cleaned out; usually after running for several weeks or months. The system varied in size or scope rather than in technique.

All of the counties within Tahoe National Forest have hydraulic mining sites within their boundaries. These were on the west side of the Sierra Nevada, usually on the western (or lower) edge of the Forest.

Perhaps the most famous of all these mines was the Malakoff Mine of the North Bloomfield Gravel Mining Company. The area had been prospected in 1851 or 1852, when "a prospecting party consisting of two Irishmen and a Dutchman" found a rich placer deposit. After news leaked, a small rush to the location ensued; disappointment led many to call it a "humbug," thus naming the creek and camp in the area. Mining continued and in 1853-54 a number of miners began employing the hydraulic method. A small dam was put across Humbug Creek, and ground sluicing was done from 1855 through 1863. Miners made money, but were unable to get at the deep gravels in the area (IBID: 1-2).

After a period of relative quiet around the area from 1861 through 1865, mining at North Bloomfield picked up. There were fourteen hydraulic mines, one employing thirteen men; but the lack of proper drainage made working the claims difficult. As hydraulicking began to produce more gold, interested capitalists began investing in the development of the big mines around North Bloomfield (IBID: 4-5). In 1865, Jules Poquillion purchased several claims in the area. A year later he organized the North Bloomfield Gravel Mining Company with Lester L. Robinson and other San Francisco capitalists (California Department of Parks and Recreation 1979: 14). The company eventually owned 1,585 acres, with an estimated $69,600,000 in gold in the gravels therein.

Lester L. Robinson was typical of the entrepeneurs who assumed the direction of the hydraulic mining industry. He came to California in 1854, at the age of thirty, after a successful career as a railroad engineer in the East. He was responsible for building the Sacramento Valley Railroad . . . the first railroad on the Pacific Coast . . . (he became) an active partner in the Pioche firm (Pioche, Bayerque and Co.) and he turned his talents to a wider field of investment. (IBID: 6)

Robinson was also a director of the Giant Powder Company and several mines in California and Mexico; he was involved in irrigated agriculture near Riverside, and invested in tin, insurance companies and oil wells (IBID: 6).

Realizing that they would need more water and better drainage to work the mine, several projects were considered. A proposed canal from the Little Truckee River was never built; but the company did purchase Rudyard (English) Dam at the head of the Middle Yuba River in 1868. This dam was the largest in the state at that time. The company also began to look for another site, and in July 1868, they engineered and began construction on a canal from North Bloomfield to Poorman Creek using a force of "800 Chinamen and 300 hundred white men." From August 7 to December 21, 1868, they built twenty-seven miles of ditch. The next year seventeen miles more were built to connect the canal to Big Canyon Creek; the canal system became known as the best in the state. When completed the ditch was fifty-five miles long, three and a half feet deep, 8.65 feet wide across the top and five feet wide at the bottom. "The ditch and distributors cost $422,106.14" (IBID: 10-11).

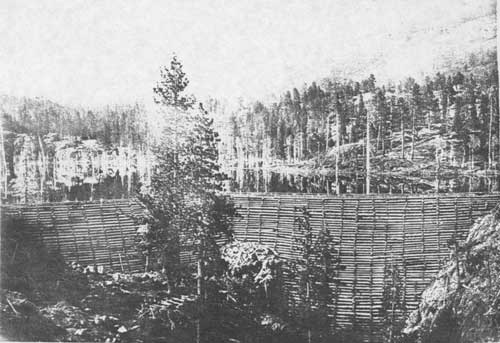

To fill the ditch the company built a reservoir and dam at Bowman's Ranch on Big Canyon Creek in 1868-1870. The dam was sixty-five feet high and 215 feet long, and built of timber ballasted with rock. A small diversion bay below the main dam put water into the canal. The dam burned in October 1871; it was temporarily repaired, rebuilt in 1872, and raised in 1876 to a height of 100 feet (IBID: 12-15).

In order to drain the mine the company built a bedrock tunnel 7,800 feet from Humbug Creek to a point 200 feet below bedrock level, allowing the gold gravels to be drained. The tunnel cost $275,574 (California Department of Parks and Recreation 1979: 15).

By 1876, the company was ready to begin full-scale activity. In July, 1876, the mine ran seven four- to eight-inch monitors twenty-four hours a day. As was the case in most hydraulic mining towns, North Bloomfield had a large number of Chinese; almost half of the miners in town in 1878 were Asian. Besides mining, the Chinese in North Bloomfield grew fresh vegetables for market. By 1880, the population of the town reached 1,229. With the end of hydraulic mining (1884-1893) the population dropped rapidly; in 1900 there were only 730 left (IBID: 16-19).

There were many other hydraulic mines in the Forest, most of which were smaller than the operations of the North Bloomfield company. Hydraulicking went on in Placer County at Dutch Flat, Emigrant Gap, and Michigan Bluff; in Nevada County in the Washington District at Alpha and Omega, and at Relief in the North Bloomfield District (Clark 1970: 45, 46; MacBoyle 1918: 45, 99). Sierra County was also the scene of extensive hydraulic mining at Morristown, Monte Cristo, Craigs Flat, Excelsior (near Monte Cristo), Eureka District, and near Downieville (Mountain Messenger 9/18/1880; Sinnott 1972: 190, 171, 195; Clark 1970: 46; Fariss and Smith 1882: 480).

One of the most extensively hydraulicked areas of Sierra County was around Brandy City. As early as 1854, the Sierra Citizen (3/4/1854) noted 150 miners at work with sluices in the dry diggings. The dry winters of the early sixties and a general "petering out in the diggings" caused hardships for many miners, a number of whom left the Brandy City area in 1864 (Mountain Messenger 8/6/1864). New finds led to renewed mining in 1867, when the Mountain Messenger described some of the mines near the city.

Everyone is piping away in a lively manner, making the best use of the water while it lasts. Van Ransalair and Co., Morgan, and Arnott and Co. are all piping away in a lively manner and the prospects are flattering for good returns. (Mountain Messenger 5/25/1867)

The main portion of the town's water supply came from a flume that connected the town and the mines to Canyon Creek, ten miles away. Known in the 1860s as the Hoosier Ditch system, it later became the Brandy City Ditch. The flume rounded a rock outcropping above Canyon Creek where iron bars supported it. The bars were still visible in the 1970s (Sinnott 1977: 150). Hydraulic mining in the vicinity of Brandy City flourished into the 1880s. The Brandy City Mining Company in 1883 began construction on a 3,400 foot long sluice tunnel scheduled for completion in 1885. The company brought in tunnel digging machinery on the first teams and wagons ever to arrive at the town from the outside world. With the new machinery in place and the tunnel near completion, the future looked bright for the mining company (Sierra Citizen 7/19/1883; 9/6/1883). Unfortunately the mines were effectively shut down by the Sawyer Decision in 1884. Several years later, the Mountain Messenger discussed its impact on Brandy City:

Times are very dull at Brandy City, but we are living in hopes that the mine will be allowed to run, which will change matters greatly. The Company will continue working the mine if the debris case, which is now before the U. S. Circuit Court, is decided in their favor. (Mountain Messenger 7/23/1892)

Despite the fact that the appeal was unsuccessful, mining continued in limited fashion at Brandy City throughout the century. In November 1907, the Brandy City Mining Company was planning to resume hydraulic mining operations. Renewal of hydraulicking enabled Brandy City to hang on as a mining settlement for several years. In 1911, the county newspaper stated that the town was "going along nicely" (Mountain Messenger 11/16/1907; 4/22/1911)

One of the most important aspects of hydraulic mining everywhere was the water delivery systems that developed around it. The canals, ditches, flumes, dams and reservoirs represent a complicated part of the hydraulic mining industry, and are among the most prominent existing historical resources on the Forest. Additionally, these water developments have served more than just mining, and have become important in irrigation and hydroelectric power generation for mines and towns. Some mining companies like the North Bloomfield Gravel Mining Company owned their own systems; more often miners bought water from water companies. These organizations, and the men who built them, often gained more gold than did the miners. Like the mining companies, they were capital-intensive, and often headquartered in San Francisco or New York (Pagenhart 1969: 6; Paul 1947: 297).

One writer has described the three "single purpose systems" that developed in the Yuba and Bear River basins; much of what went on there applied to the American River Basin as well. The three systems were hydraulicking, hydroelectric power generation, and irrigation. Hydraulic mining use of water has been discussed above.

The second of these systems, hydroelectric power generation, grew directly out of the accumulated technical knowledge and water supplies that were concentrated in the former mining area. The third system, irrigation, needed support from the beginning, and survived in the Yuba-Bear area primarily because of the change in public attitude that took place at the end of the nineteenth century. (Pagenhart 1969: iii)

Initial construction of water systems began in the 1850s. In Nevada County in the spring of 1852 the Little York Ditch was dug, tapping the Bear River near its headwaters and sending water eighteen miles west to You Bet. In 1858, another ditch was built into the area, and between 1852 and 1855 the Walloupa Ditch was dug fifteen miles up Steephollow Creek (IBID: 94). This early development of ditches also went on in Placer and Sierra counties. In 1855, the El Dorado Water Company had thirty miles of canal and laterals near Michigan Bluff; the Sacramento Daily Union (12/14/1854) reported on the ditches of Sierra County in December of 1854. These included Havens and Craycroft Wisconsin Ditch, Minnesota Ditch, Halfway Water Ditch, Chipps Digging Ditch, Walton and Company's Ditch, and the beginning of the Sierra Nevada Lake Water and Mining Company's ill-fated ditch from the Sierra Nevada crest to Minnesota (Thompson and West 1882: 151).

The mines and water companies of San Juan Ridge also grew between 1850 and 1853, and their story is instructive as an example of water development for mining. By 1851, the surface placers of the ridge were "known and claimed," and ditches began to serve the long toms and sluices that mined them. A ditch was run twelve miles from Shady Creek to French Corral in the winter of 1851-1852. By 1853 ditches were noted running from Poorman Creek to Eureka (later Graniteville). Miners and prospectors explored down the ridge from there, having come up the South Fork of the Yuba River to Poorman Creek and up the creek to Eureka. The experienced ditch builders also began the Grizzly Ditch to Cherokee in 1854, which tapped Grizzly Creek and Bloody Run. A branch of this ditch ran from Cherokee toward North San Juan in 1853-1854. The last of the pre-hydraulic mining ditches dug in the area were the Poorman Creek Ditch from Poorman Creek to Eureka and Moores Flat, and the Irwin Ditch from Poorman Creek to Relief Hill and Humbug Creek. The Irwin Ditch had been under construction since 1851 (Pagenhart 1969: 96-99).

|

|

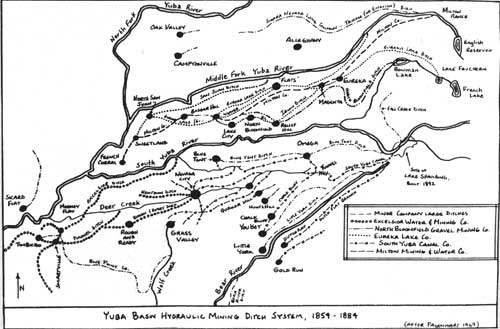

YUBA BASIN HYDRAULIC MINING DITCH SYSTEM, 1854-1884 (after

Pagenhart 1969) (click on image for a PDF version) |

After hydraulic mining began the demand for mining water grew faster than these early ditches could manage. Mining companies began to look for more certain supplies.

In the early mining days, operations were often completely suspended during unseasonal droughts. The economics of later corporate enterprise, however, made intolerable such unreliable water supplies, and the main reason for the early construction of headwater storage dams. Storage facilities had to be planned for a possible extension of the regular summer drought well into winter. (IBID: 75)

The water systems developed during the hydraulic period (1854-1884), whether owned by mining or water companies, had similar systems of dams and ditches. Water systems usually had three types of dams: diversion, storage, and distribution. Diversion dams were built across a waterway to direct the flow of the creek or river into the mining ditch. These rapidly developed into larger storage dams simply by enlarging the diversion wall. Storage dams were also built to increase the capacity of Sierra Nevada lakes. As early as 1850 rock and flashboard barriers were built across the outlets of White Rock and Upper Peak lakes. This became a popular means of dam building; in 1855 several others were built, and between 1855 and 1865 twelve such enlargements were made. Between 1865 and 1885 nearly twenty-four more were added (IBID: 112-113). Other storage dams were built in narrow canyons or at strategic locations in headwater valleys. Rudyard Dam was built in 1858 of dry laid stone faced with boards. Bowman Dam was built in 1869 for the first time in the same fashion (Jackson 1967: 10-13). Masonry dams were not built in the Yuba-Bear basins until the 1890s when they were needed "for other and more permanent uses." Wood-faced dams were often poorly built and suffered from rotting wood. By far the greatest number of dams were the small distribution/diversion dams at branch locations or at the end of the canals. These were small, shallow often temporary structures used to store several hours supply of water and to regulate flows toward various customers (Pagenhart 1969: 113).

The ditches and flumes that carried water in these systems varied in size and method of construction. One flume in Sierra County was twelve by eighteen inches; by contrast the North Bloomfield Ditch was three and a half feet deep, 8.65 feet across the top and five feet across at the bottom (Sacramento Daily Union 12/14/1854; Jackson 1967b: 10-11). In general, flumes were less expensive than canals in rough terrain. The successful ditches of the mid-1850s were those that had been built early on with sufficient capacity to sell water to the hydraulic mines. Because of the large demands put on the ditches, only those that had been built as big as possible were usable and thus the companies that built them survived (Pagenhart 1969: 114). Ditch tenders, who had cabins or stations along the ditch route, monitored and maintained the canals (Jackson 1967 b: 50-51, 13). Examples of these ditch tenders' cabins still exist within the Forest (Tahoe National Forest Archaeological Site Forms).

Ditches and canals varied not only in size, but in length. Many were small, local ditches used by the smaller placer mines; however, some ditch systems attained massive proportions. The South Yuba Canal Company's system included 275 miles of ditch on the ridge between the Bear and South Fork of the Yuba River; the Eureka Lake and Yuba Canal Company, which had begun operations in 1858, absorbed smaller companies so that by 1875 it controlled 300 miles of ditch, with a main canal running from Lake Faucherie to North San Juan, a distance of some sixty-five miles (Kelley 1959: 4). By 1879, there were 900 miles of ditches in Nevada County, 1,000 miles of smaller ditches were added. The total cost of the ditch system was estimated at $7,000,000. Thus, these large companies rivaled the large corporate mines in size and level of investment.

Some of the flume systems included sections that were considered "engineering marvels." The Eureka Lake Company built two high flumes: the "National Flume," which spanned 1,800 feet and was sixty-five feet high; and the "Magenta Flume" across Cherry Hill Gap, 1,400 feet long and 126 feet high (Pagenhart 1969: 128).

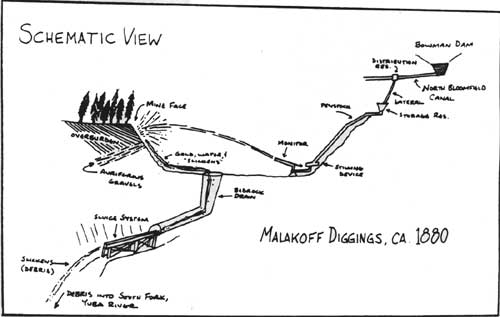

Once water reached the hydraulic mine through the distribution system, it was applied to the mine face. Water ran down iron pipe penstocks to build pressure, through a "stilling" device to reduce turbulence and catch stones, and then out through the monitors, hitting the mine face with tremendous force. A reporter for the San Francisco Bulletin wrote about his visit to the Malakoff Mine in 1879, and described the use of the hydraulic monitor.

. . . The water has done its work here, and washed out all the loose earth and smaller rocks. Now the next thing is to get rid of the large boulders, often weighing tons. They must be blasted into fragments so small that when the water is turned on here again they will be swept down and out through the tunnel. They need not be very small for that. A boulder of six or eight hundred pounds weight goes out like a flash. So here are thirty or forty men, busy with drills, in a great hammering company. It is, at this instant, wild music. After from fifty to a hundred holes have been drilled, and loaded with giant powder and properly prepared with fuses of exactly the same length, the men will take irons of about three feet long, made red hot at one end, and run from boulder to boulder touching the ends of fuse. This being done, they will scud hastily into a grim looking 'block house,' a couple of hundred yards distant, built of old flume blocks and roofed with logs. Then, after a brief space, there will be wild artillery, and much smoke.

We descend into the mine by steps beside a V-shaped trough for sliding blocks down, and turn our steps to the white streams of water which are at the western end of the mine being held against the bank. There is a real pleasure, very distinct, but hard to describe, about this gigantic force. This is the water which left the Bowman reservoir a few hours ago, and has been worried and tumbled and beaten into foam until one might easily believe that it comes out with not merely the force of so much gravity, but also with a wicked, vicious, unutterable indignation. The black pipe, three feet in diameter, leads down the cliff, and across the mine. It becomes smaller, and ends in a jointed, elbow-like pipe, with a movable nozzle. By laying the weight of a hand on the lever, this rim-like nozzle enters the edge of the stream, and the weight of the water turns the machine to any angle desired. It may be dropped till it foams at the operator's feet; it may be raised almost upright, or made to sweep the circumference of a circle. It is not hard work to manage one, but it requires much experience and judgment to know how to use the stream to best advantage, and with greatest safety. Large boulders and lumps of pipe-clay are slowly washed down to the bed-rock for the blasters to handle, but rocks two feet in diameter fly like chaff when struck by the stream. The actual work of tearing down the cliff is hard to see, for there is a cloud of red foam hanging over the spot. You hear little rattling and slipping noises through the incessant roar, and a stream which seems ten times greater than could come out of the pipe, flows down the dripping pile, and so into the rock-channels which lead to the tunnel. (Quoted in Jackson 1967b: 60)

A basic description of the North Bloomfield system at peak usage will help to put the complicated water system in perspective. A gallon of water destined for use at the Malakoff Mine might start from Bowman Dam and be placed in the North Bloomfield main ditch. It would then flow the fifty-five miles to North Bloomfield fairly rapidly because of the twelve to sixteen foot per mile grade (Jackson 1967b: 25). Upon reaching North Bloomfield the water would be transferred by a lateral line to a storage reservoir, where it would then be directed down a penstock, through a stilling box and out the monitor. The water would wash rock, dirt, and gravel off the mine face and into the sluicing system and main drainage tunnel. It would be run down ever more gentle sluice systems in order that the maximum amount of gold be extracted from the gravel before "the thick muddy stream is allowed to find its own way down without hinderance" (San Francisco Bulletin 1879, quoted in Jackson 1967b: 61)

|

|

SCHEMATIC VIEW - MALAKOFF DIGGINGS, ca. 1880 (click on image for a PDF version) |

A large number of water companies provided water for mines within the Forest. Mines from Michigan Bluff in Placer County to Poker Flat on the northern border of Sierra County were supplied either by water companies or by the miners own systems. The history of four of these companies is illustrative of the general trend of mining water development. Of the four, two were able to survive the end of hydraulic mining and shift their activities to hydroelectric power generation and irrigation; the other two did not and have disappeared. All four companies began their operations at about the same time, in the mid-1850s. They were the Eureka Lake and Yuba Canal Company the Middle Yuba Canal and Water Company, the Excelsior Company, and the South Yuba Canal Company. The North Bloomfield system rivaled these in size, but because it was built by a mining company it has been discussed separately.

The Eureka Lake and Yuba Canal Company, Consolidated, began as a group of small ditch companies on San Juan Ridge that merged in 1853. By 1855, a group of French miners and San Francisco investors led by B. Faucherie obtained water rights to lakes and streams in the headwaters of Canyon Creek. Two storage dams were built, each over forty feet high, doubling the capacity of Lake Faucherie and Eureka Lake. The company planned on a large scale, thus ensuring sufficient supply for hydraulickers. The Eureka Ditch had a capacity of 3,000 miners inches, crossed the saddle between Lake Faucherie and Weaver Lake, and then moved along the north-facing side of the canyon of the Middle Fork of the Yuba River. At Eureka South (Graniteville) all the ridge ditches came together because of the flat at the site, "making it possible to convey water from one side of the Ridge to the other, or to make connections with and transfers from other ditches" (Pagenhart 1969: 127-128). After the Magenta Flume crossed Cherry Hill Gap it connected with the Irwin Ditch; the main ditch went on sixteen miles to Bloody Run and Columbia Hill. By purchasing smaller companies and their ditches the Eureka Lake Company eventually supplied water to all gravel areas on San Juan Ridge as far west as Cherokee. As a part of their operations the company also purchased three mines and laid out Lake City west of the Malakoff Mine. The company's system was expanded by the acquisition of two other ditch companies. In 1859 they bought the Miners Ditch Company, which was formed by a group of miners who laid out and built a canal from the area of Moores Flat to the Middle Fork of the Yuba some twenty miles east in five months during 1855, at a cost of $175,000. The Miners Ditch had a capacity of 750 inches of water, was three feet across the bottom and five across the top. The miners who built it used very little outside capital and apparently were unable to sustain operations. The Miners Ditch Company also operated Grizzly Ditch. A carrying capacity of 750 inches was apparently the minimum necessary to stay in business; the successful companies had capacities running from 750 to 3,000 inches, and typically ended up purchasing the smaller ditches and using them as part of their larger system. The Eureka Company purchased the Weaver Ditch (or "Memphis and Orleans Race") in 1860. The ditch, built between 1853 and 1859, had insufficient capacity and went bankrupt (IBID: 125-130). By 1882, Eureka Lake Company's operation included 163 miles of ditches and flumes with a capacity of 5,800 miners' inches (State Minerologist 1882: 161).

The Middle Yuba Canal and Water Company began operations in 1853, and dug a canal fifteen miles upstream from North San Juan; the system eventually was forty miles long. Once a sufficient water supply was secured, the area around North San Juan became a center of hydraulic mining activity. The Middle Yuba Canal, "with later expansions to the south . . . supplied mines along the entire gravel channels to French Corral." In 1857, the company purchased the western end of Grizzly Ditch. The Middle Yuba Company eventually merged with the Eureka Lake Company in 1863 (Pagenhart 1969: 127).

The mining water companies exerted great financial pressure on the miners by demanding high prices for their water. The hydraulickers struck in 1854 and again in 1859, refusing to buy any water at all. The strike of 1859 forced rates down temporarily until the water companies agreed to a single water rate. The merger of the two major San Juan Ridge companies in 1863, and their purchase of mines, served to mitigate the power of the miners to affect reductions in water rates (Pagenhart 1969: 127; Paul 1947: 325).

The two other water companies, the South Yuba Canal Company and the Excelsior Company, built their works to serve areas other than San Juan Ridge. The systems of these two companies survived, at least in part, beyond the era of hydraulic mining. They did so by becoming involved in activities other than supplying water to the mines.

The Excelsior Company began operations in the mid-1850s, and by the mid-1860s had grown quite large through mergers with smaller companies. "The Excelsior Canal Company incorporated all water claims and ditch companies south of the South Fork of the Yuba River, except those of the South Yuba Canal Company. Between them, these two giant companies came to share control of the mining and water industry in the entire southern part of the Yuba Basin, from Smartsville to the headwaters of the South Yuba River." In 1861, the Excelsior Company consolidated with the Union Ditch Company and with an extension called the "China Ditch" brought water to Smartsville (Pagenhart 1969: 121). Unlike the South Yuba Canal Company, most of the Excelsior's operations were outside the exterior boundaries of Tahoe National Forest.

The South Yuba Canal Company was founded in the early 1850s to supply water to placer operations near Nevada City. Three miners, Spencer, Rich and Fordyce, ran a ditch from Upper Deer Creek to Nevada City some twenty miles west in 1853-54. Rich and Fordyce surveyed shortly thereafter the upper reaches of the South Fork of the Yuba, looking for diversion sites and securing water rights. In 1855, a merger with smaller companies in the Nevada City area strengthened their operation. Soon thereafter they began their first major project, the South Yuba Canal, which in many places, follows the same route as the South Yuba Canal does today. When the canal was first completed it was called "the most stupendous ditch operation in the state" (IBID: 119). The system required the construction of a flume that ran along the granite shelf, as well as the digging of two bedrock tunnels. When completed, the canal was eighteen miles long and had a capacity of 8,500 inches. Additions to the system supplied water to Alpha, Omega, Gold Hill Blue Tent and Nevada City (via Deer Creek). Water at first was diverted from the South Fork of the Yuba River near present Lake Spaulding and carried over the Bear River Divide. The company built a large number of distribution reservoirs, and dammed twenty small lakes to increase their capacities. The system took five years to complete. Between 1860 and 1864 the company constructed the Meadow Lake dam; it measured forty-two by eleven hundred and fifty feet and increased by ten times the storage capacity of the lake. Branch canals (laterals) were constructed on ridges that trended north-south and crossed the main canal. One, the Chalk Bluff Branch, ran eighteen miles to Red Dog and You Bet carrying 3,000 miners' inches. In 1864 a branch was run twenty-four miles to Dutch Flat. Water used at Dutch Flat, then, traveled from the headwater area of the South Fork of the Yuba, across the head of the Bear River Valley and worked the mines at Dutch Flat. As the water and tailings were dumped into the North Fork of the American River the canal system completed one of California's earliest interbasin water transfers (Pagenhart 1969: 120). By 1882 the company's canals totaled some 123 miles and had a carrying capacity of 7,000 miners' inches of water (State Minerologist 1882: 161).

The South Yuba Water Company developed out of the South Yuba Canal Company in 1880. As hydraulic mining operations were phased out between 1884 and 1900, the company extended the system to supply irrigation water to foothill fruit ranches in Nevada and Placer counties. Member/owners of the South Yuba Water Company organized the Central California Electric Company in January, 1895, thinking to use the power generated by water dropping from high places along their canals. The construction of Spaulding Reservoir in 1892 with a capacity of about 6,000 acre-feet, covering 216 acres of land, increased their storage. Water was sent to powerhouses, the first built at Newcastle in 1895, and another soon thereafter at Auburn, followed by the Alta Powerhouse in 1901. In 1901 the Central California Electric Company was taken over by the California Electric Company as a part of its larger operation. In October, 1905, Pacific Gas and Electric Company was organized as a holding company to acquire the stock of California Electric Company and other power companies in the state. Since January 1, 1906, Pacific Gas and Electric has owned and operated the systems of the various companies that it bought. Thus, Lake Spaulding passed from the hands of the South Yuba Water Company to Pacific Gas and Electric (Graves to Strong [letter], December 15, 1913). The evolution of the South Yuba Canal Company then demonstrates the historical process of modernization in mountain water development, from hydraulic mining to irrigation to corporate consolidation for the purpose of hydroelectric power generation.

The inclusion of the South Yuba system into the other companies was illustrative of other such activity in the area. In fact, Eugene De Sabla Jr. had been active in promoting and building the power system at Lake Vera as a part of the Nevada County Power Company and the Colgate Power House on the main Yuba River. These became part of the Bay Counties Power Company organized in 1900, which sold its power 140 miles away in Oakland, using one of the earliest long-distance transmission systems in the world. De Sabla was later a founder of Pacific Gas and Electric Company. Mining water, then, went from an operation undertaken in the early 1850s by miners, through mergers and consolidations to huge water companies, some of which were swallowed up after the end of hydraulicking and made part of irrigation and power systems. The shift toward generation of electrical power, made possible by the invention of high-speed wheels (like the Pelton) and innovations in electrical science between 1870 and 1890, led the water companies in the Yuba Basin toward electrical power (Pagenhart 1969: 153-68). Additional dams were built elsewhere on the Forest and then converted to hydroelectric power at about the same time. Foundry Dam near Downieville was built in 1867 to power machinery at the "Foundry and Machine Shop." After 1896 it supplied electricity for the town's first electric lights. The dam has since been destroyed (Tahoe National Forest Historical File).

Sierra County, like the other mountain counties with Tertiary Gravels, had a large network of ditches. In 1858 there were 183 miles of ditches with a total capacity of 22,180 inches. The town of Downieville was served in 1882 by five different water companies, drawing water from the Yuba River, local tunnels, ravines, and flume systems (Fariss and Smith 1882: 463, 483). Washington, in Nevada County, was still getting domestic water in 1969 from the Canyon Creek ditch built in the early 1850s (Slyter 1969: 93-6).

Hydraulic mining was an inexpensive means of exploiting the deep gravels because relatively few men could do the work of many through the use of a monitor. Unfortunately it was also enormously destructive, not only to the area mined but also to the areas downstream from the hydraulic mines. As the tailings (or "slickens") began to damage downstream agricultural land a movement grew to stop hydraulic mining, or at least force it to control its waste. The argument was important in a larger sense, in that it forced the people to decide if gold mining or agriculture was to be central to California's future.

Farmers and towns downstream of the hydraulic mines began to notice the changing conditions in the rivers in 1856. In 1862, a flood damaged the city of Marysville, which along with Yuba City was especially vulnerable because of its location at the junction of the Yuba and Feather rivers. By 1868, the beds of the rivers were higher than the city streets in Marysville, forcing the city to build levees that eventually cost over $1,000,000 (Kelley 1959: 57-8).

Farmers and miners argued over who was at fault. The miners stated, correctly, that they were there first. More important, the city of Marysville was heavily dependent on trade with the mines — even many of the hydraulic monitors were manufactured there. Besides, it was impossible to know which mine caused damage to a specific farm, making lawsuits difficult to pursue. Worry and anger was the only reaction until 1873, when the citizens and farmers of the Sacramento Valley began to organize against hydraulic mining. The first suits resulted in decisions unfavorable to the farming interests. Initially there was little support for the farmers in towns like Marysville that depended on mining trade. The attitude of Marysville residents changed after January, 1875 when a city levee broke and flooded the city, killing a small boy and half burying the city in mud. Protest meetings began to spread, and the suggestion was made that the legislature rather than the courts should be the target for complaint (IBID: 59-69). Miners realized that as pressure against hydraulic mining grew, a counter-organization would be required. "Called into being by a threat to the industry's existence, it [the Hydraulic Miners Association] assumed not only the task of defense, but of consolidation as well" (IBID: 88). Membership was open only to owners of mine, water or tailing sluice companies. Votes in the Hydraulic Miners Association were tied to the production level, one vote for each $5,000, thus giving big companies control of the organization (IBID: 89-90). Discussion of the waste problem began to focus on building debris dams to impound slickens. By 1882, the U. S. Army Engineers were surveying for debris dam sites on the Yuba, American, Feather, Calaveras, Mokelumne and Consumnes rivers (Mountain Messenger 1/14/1882).

In 1882, the farmers organized Anti-Debris associations which spread from Marysville and Yuba City to Colusa, and later to Chico. Soon the anti-debris movement spread throughout the entire Sacramento Valley. In May, 1882, county supervisors from Sutter, Yuba, Yolo, Colusa, Tehama, Solano, Butte, and San Joaquin counties met and agreed to organize the State Anti-Debris Association. Only Solano, Tehama, and later San Joaquin counties did not take part (Kelley 1959: 194-196, 212-213).

A series of cases led in 1884 to what has become known as the Sawyer Decision, which outlawed the dumping of mining debris into rivers (Bean 1978: 233). Tempers had run high. On June 18, 1883, the Rudyard (English) Dam on the headwaters of the Middle Yuba river burst; the resulting flood caused considerable damage and death downstream. Accusations as the cause of the dam's failure served to heighten tensions further (Jackson 1967: 84-88). Attempts to conciliate the differences did little, and as the courts affirmed the Sawyer Decision on appeal, hydraulic mining faded. The Sierra County Tribune (12/1/1884) described the impact of the decision on a local mining district:

Effects of the Anti-Debris Decision. Brandy City — All are leaving who can get away. Sawmills have shut down. Six ranches, wholly dependent on mining, are ruined. Most of the men who remain here are waiting to see if something can be done to start up. This once prosperous camp is now ruined.

The article went on to state that the value of mines, ditches and other related property had lost seventy-five percent of their previous value.

After the Sawyer Decision, miners continued to look for ways to operate hydraulic mines within the limits of the injunction. In addition, a Debris Commission was set up by the U. S. Congress that began to study the problem in 1889. One of the commission's duties was to locate sites for debris restraining dams (Mountain Messenger 3/30/1889). Finally in 1893, a federal law, the Caminetti Act, set up a permanent Debris Commission and legalized hydraulic mining under certain restricted circumstances (Bean 1978: 233). Some of the largest mines tried to operate under the terms of the Act, but found that debris dams were filled far too fast. Thus hydraulic mining faded out after 1884 and was carried on, if at all, on a small scale (MacBoyle 1918: 5).

Gold mining did not end with the Sawyer Decision and Caminetti Act; as noted above, drift gravel mines and deep quartz operations continued well into the 1900s. Better mining techniques and advanced equipment allowed the exploitation of deeper deposits and lower grade ores. Established quartz mining areas like Alleghany continued to be active and develop. Overall, however, in the years following 1884, there was a general decline in gold production (with the exception of dredge operated mining) and the industry did not fully recover until the 1930s (Clark 1970: 6).

Gold mining has held a large share of the attention in California and within Tahoe National Forest. Nevertheless there has been some limited exploitation of metals and minerals other than gold. The most prominent of these were silver and copper. Silver and copper deposits were found in Sierra Valley, Antelope Valley, and their vicinity in 1862-3, and the settlement of Antelope City was established southwest of Loyalton during the excitement. Shafts were sunk until 1866, when mining was discontinued. In 1864, some evidence of silver and gold was found in Bear Valley northeast of Sierraville (Sinnott 1976: 9). A brief gold and silver excitement started in 1861 in the Tahoe District located to the north and west of Lake Tahoe. During the excitement little settlements were planned and some buildings were erected in the "towns" of Claraville and Knoxville (near the mouth of Squaw Creek), Elizabethville (a few miles north of Kings Beach), and Neptune City (north of Lake Tahoe) (Gudde 1960: 345, 74, 188, 108, 237).

|

| ENGLISH (RUDYARD) DAM. |

|

| OMEGA MINE, WASHINGTON RIDGE. |

Copper mining excitement also spread to the Bear River Valley in the Gardner Bar District in 1853-64. Small settlements called Wilsontown and Superior were set up, ore was shipped to San Francisco, and good prices obtained. As prices fell in 1864, excitement waned and after 1864 "few, if any, copper mines were worked in Placer County" (Thompson and West 1882: 206-7). In Nevada County near English Mountain and Bowman Lake copper was mined in the 1890s and early 1900s (Clark 1970: 46) Copper mines in this area were developed during and after World War I; however, most were worked sporadically in the late part of the nineteenth century (MacBoyle 1918: 85-91).