|

Public Camp Manual

|

|

NATURE AND ORDER OF IMPROVEMENTS

IV. TOILET FACILITIES

Proper sanitation is a matter of great importance in all camp development. Following the planning of roads and water systems, the location of toilet facilities should be planned carefully, in view of the danger of pollution of water supplies. This is well set forth by the California Department of Public Health, as follows:

"The principles of good mountain sanitation are simple. Burn or bury all refuse, and use care not to contaminate streams.

"Of all waste materials, the most offensive and most potentially dangerous are intestinal discharges. The direct discharge of such material into any mountain stream is obviously a cause for immediate danger to persons below who may drink from that stream. And direct discharge does not only mean passage immediately from the intestines to the stream. A rainfall results in general washing off of the land, and accumulations of fecal matter on stream banks or in dry water courses may be expected to reach the stream sooner or later. Do not be deceived by the common statement that a rapidly flowing stream purifies itself within some special number of feet. The life and virulence of a disease germ are measured in days not distance. The faster the stream flows, the longer will be the journey of contamination."

In California, almost without exception, final disposal of camp wastes must be made either into the soil through pits or cesspools, or by sub-surface irrigation. Legislation prohibits the discharge of untreated sewage onto the surface of the ground or into streams.

Toilets must be erected before any area is opened to the public for camping or picnicking. Various types of toilets may be used, the selection being dictated by local conditions,

Certain fundamental rules may be laid down as to location of toilets, as -

(1) Toilet facilities should be located in accessible places, so arranged throughout the camp that no camper will have to travel more than 400 feet to a toilet.

(2) A pair of single toilets should be erected for each 8 - 10 camp units, larger toilets used in proportion. In order to accomplish this, a general scheme of location of camp sites must be planned in advance, to assure proper distribution of the toilet facilities.

(3) Pit toilets should never be located above a spring or within 200 feet of any stream.

(4) Wherever possible, locate toilet buildings in such a way as to utilize natural shrubbery as a screen. Planting should be resorted to in developing more adequate screening. When single and double toilets are erected, separate buildings should be provided for men and women.

(5) Urinals should be provided wherever they can be justified on the basis of use.

The designs of double and multiple toilets shown in this Manual shall be standard hereafter. No more galvanized iron toilets will be constructed.

All toilets of whatever type should receive frequent attention throughout the camping season. The buildings should be cleaned and swept out, and in the case of pit toilets the vaults should be treated with some good liquid disinfectant. It will be necessary also to wash the outside of the bowls occasionally, using soap and water.

Toilet paper containers, designed to hold the square folded sheets, should be installed in toilet buildings in all camps that have an appreciable amount of use.

Angeles Metal Toilet Stool

The Angeles metal toilet stool has been accepted as standard, and should be installed in all pit and chemical toilet buildings. Except in isolated hunters' camps, buildings which are equipped with wooden box-type seats should be remodeled immediately for installation of the metal stool, or replaced by new buildings as necessity demands. Specifications of this stool follow:

BODY OF STOOL: 15 inches high with perpendicular front and sloping back made of 20 gauge iron, with lock joint down the back. Body dimensions are 20 inches from front to back and 16-1/2 inches across at the bottom, with the front and the back ends curved with the same radius as the top, which is 16-1/2 inches diameter and circular.

FLANGE AND PROJECTION: Flange is made of 16 gauge iron, 1 inch wide and is integral with a 3-inch projection designed to fit through the floor. The 3-inch extension is at right angles to the floor flange, not sloping in the back as above the floor line. Six, three-sixteenth inch holes, centers 1/4 inch from the outer edge of the flange and an equal distance apart, offer a means of fastening the stool to the floor. The flange and projection are securely fastened to the body of the stool.

|

| Angeles Metal Toilet Stool |

TOP OF STOOL: 16-1/2 inches in diameter and circular with 1/2-inch flange to fit snugly over the body of the stool, and riveted thereto. Made of 16 gauge iron with a smoothly cut opening conforming with dimension given under "Seat".

SEAT: Consists of two crescent-shaped pieces of 1-inch birch, the outer edges being a segment of a 14-inch circle. The blocks are 3 inches wide at the widest point. Each is attached to the top by means of three screws inserted from underneath. The blocks are so placed as to leave openings of 4-inches front and back, and 8-1/4 inches at the widest point. They are comfortably shaped and finished with three coats of clear varnish.

METAL COVER: 20-gauge iron, 14-1/2 inches diameter inside and 1 inch deep with curved sides. Has a flat flange or bead at bottom, 1/4 inch in width, entirely around the cover. It is fitted with a substantial brass hinge, 5 inches wide, which is attached by brass posts and nuts 1/4 inch in diameter.

PAINT: If galvanized iron is used, treat it with vinegar and paint with black enamel inside and grey enamel outside. If made of black iron, it should be given a priming coat of red lead, followed by two coats of good metal paint.

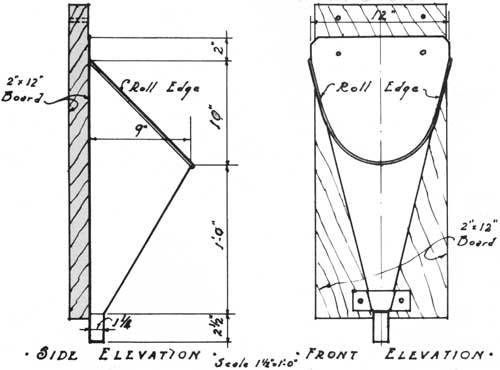

Urinals

Urinals should be installed in camp toilets wherever such installation can be justified on the basis of use, A regular commercial-type urinal should be used in connection with flush toilets. The simple urinal shown below is recommended for use with chemical or pit toilets.

|

|

Inyo Urinal Made of 18-gauge enameling stock. Finished inside and out with one ground coat and two finish coats of white enamel, the final coat being acid-resistant. |

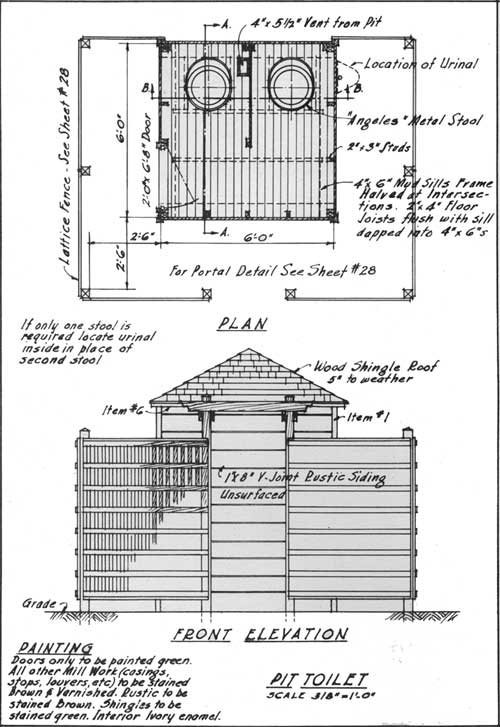

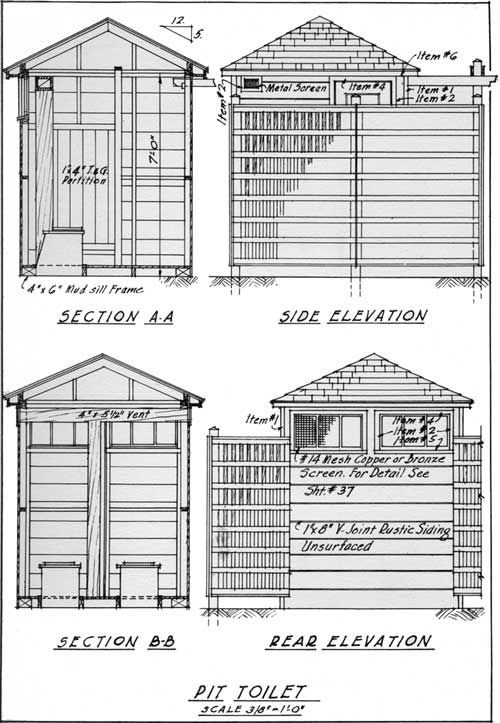

Pit Toilets

Pit toilets will prove satisfactory in the majority of forest camps, where there is little danger of stream pollution. They should be located in accordance with the general rules already discussed, particular care being taken to keep them away from water courses and springs. Vaults should be at least six feet in depth and where there is danger of cave-ins they should be walled or timbered. The larger the vault, the longer will the pit be usable, and frequent moving of toilets is not desirable. The vault must be kept dark and rodent-proof. A redwood-sill foundation for the building should be provided to prevent sloughing of material into the vault and resultant holes through which squirrels and rats might gain access to the pit. A strip of 1-inch mesh wire, a foot or so in width, should be nailed to the redwood sill all the way around, and dirt filled in around it. This will discourage small animals burrowing through to the pit.

The designs shown on pages 26 to 28 shall be used in constructing pit toilets.

MATERIAL LIST FOR PIT TOILET

| Mudsills | 4x6 | Redwood or Red Cedar #1 Heart Common | 4 pcs. | 6-0 |

| Joists | 2x4 | same | 4 pcs. | 6-0 |

| Stool Header | 2x4 | same | 1 pcs. | 6-0 |

| Floor | 1x4 | "C" Grade Flat Grain Douglas Fir T&G Flooring | 23 pcs. | 6-0 |

| Studs & Trimmers | 2x3 | #1 Common Douglas Fir S1S1E | 12 pcs. | 14-0 |

| Plates | 2x3 | #1 Common Douglas Fir S1S1E | 8 pcs. | 6-0 |

| Hip Rafters | 2x4 | #1 Common Douglas Fir S1S1E | 4 pcs. | 6-0 |

| Jack Rafters | 2x4 | #1 Common Douglas Fir S1S1E | 4 pcs. | 6-0 |

| Bridging & Blocking | 2x3 | #1 Common Douglas Fir S1S1E | 8 pcs. | 6-0 |

| Roof Sheathing | 1x6 or 1x8 | #2 Douglas Fir or #3 Ponderosa Pine Common Shiplap | 100 B.M. | |

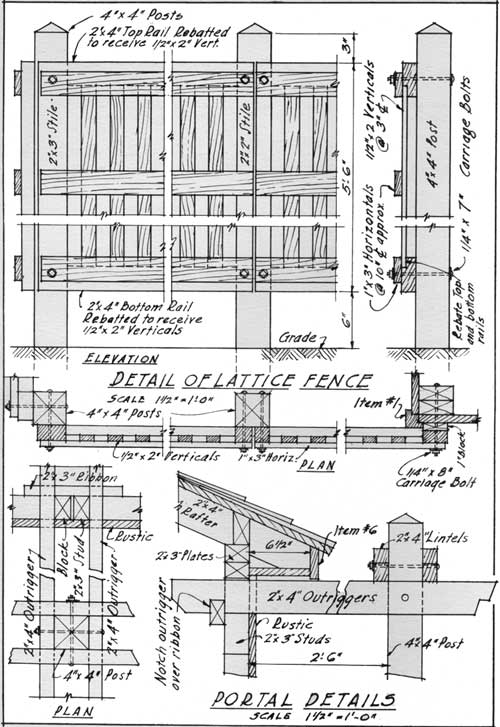

| Lattice Posts | 4x4 | #1 Heart Common Redwood or Red Cedar S4S | 8 pcs. | 10-0 |

| Outlookers | 2x4 | same | 3 pcs. | 18-0 |

| Outlookers | 2x4 | same | 2 pcs. | 8-0 |

| Cap | 2x4 | same | 1 pcs. | 10-0 |

| Rustic | 1x8 | V-jointed Clear All Heart Unsurfaced Redwood or Red Rough side out |

(32 pcs. (6 pcs. | 6-0 8-0 |

| Corner Beads | Item 1 | Clear All Heart Redwood or Red Cedar to detail | 4 pcs. | 8-0 |

| Screen Sill | Item 5 | Clear All Heart Redwood or Red Cedar to detail | 1 pcs. | 6-0 |

| Cornice Facia | Item 6 | Clear All Heart Redwood or Red Cedar S4S | 4 pcs. | 8-0 |

| Cornice Soffit | 3/4"x6-1/2" net | same | 4 pcs. | 8-0 |

| Casings | Item 2 | Clear All Heart Redwood or Red Cedar to detail | 1 pcs. 1 pcs. | 14-0 10-0 |

| Screen Sills | Item 8 | All Heart Clear Redwood or Red Cedar to detail | 1 pc. | 6-0 |

| Stops | 1x2 | same S4S | 4 pcs. | 10-0 |

| Partition | 1x4 | "C" Grade Douglas Fir or Ponderosa Pine V-jointed partition stock | 6 pcs. | 8-0 |

| Partition Frames | 2x3 | #1 Common Douglas Fir S1S1E | 1 pcs. | 8-0 |

| Quarter Round | 3/4" | Douglas Fir or Ponderosa Pine | 4 pcs. | 8-0 |

| Vent Duct | 1x6 | Clear All Heart Redwood or Red Cedar S4S | (2 pcs. (2 pcs. | 14-0 12-0 |

| Lattice | 1x3 | same | (8 pcs. (24 pcs. | 6-0 10-0 |

| Lattice | 1/2"x2" | same | 92 pcs. | 6-0 |

| Lattice Frame | 2x4 | same | (2 pcs. (6 pcs. | 6-0 10-0 |

| 2x3 | same | 12 pcs. | 6-0 | |

| 2x2 | same | 4 pcs. | 6-0 | |

| Shingles | Clear 100% edge grain Redwood or Western Red Cedar 16" 5/2 butts 1 square 4 bundles | |||

| Screens | 2 screens to detail, approx. 2'-4" x 1'-3" x 7/8", cut into 3 lights. Screened with 16-mesh copper or bronze wire cloth. | |||

| Door | 1 2-0 x 6-8 x 1-3/8 stock, 5 solid raised panels. | |||

| Hardware | ||||

| Nails | 5 lbs. 16d common | |||

| 10 lbs. 8d common | ||||

| 5 lbs. 8d common galvanized | ||||

| 10 lbs. 6d smooth box zinc coated | ||||

| Bolts | 8 1/4"x8" carriage bolts with nuts and washers. | |||

| Lattice | 76 1/4"x7" carriage bolts with nuts and washers. | |||

| Hinges | 1 pair 3-1/2x3-1/2 wrought steel loose pin butts galvanized, with screws. | |||

| Lock | 1 mortise lock set complete with knobs, key plates and strike. | |||

| 1 14" spring door closer, equal to Chicago #283. | ||||

| Screen | 2 sq. ft. bronze or copper 16 mesh wire cloth. | |||

|

| (click on image for a PDF version) |

|

| (click on image for a PDF version) |

|

| (click on image for a PDF version) |

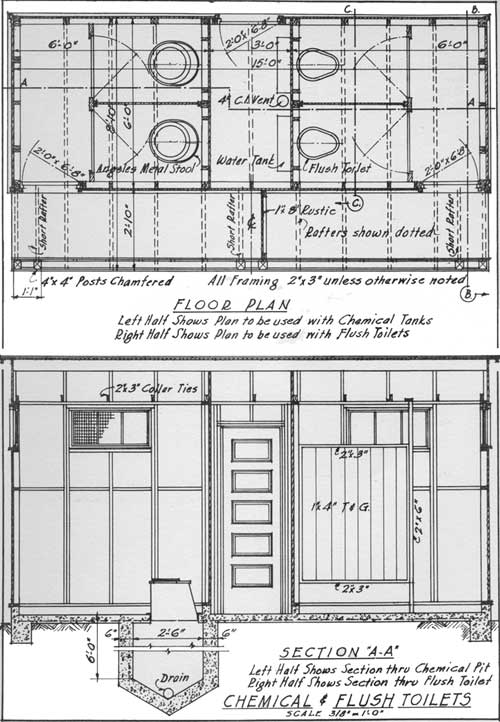

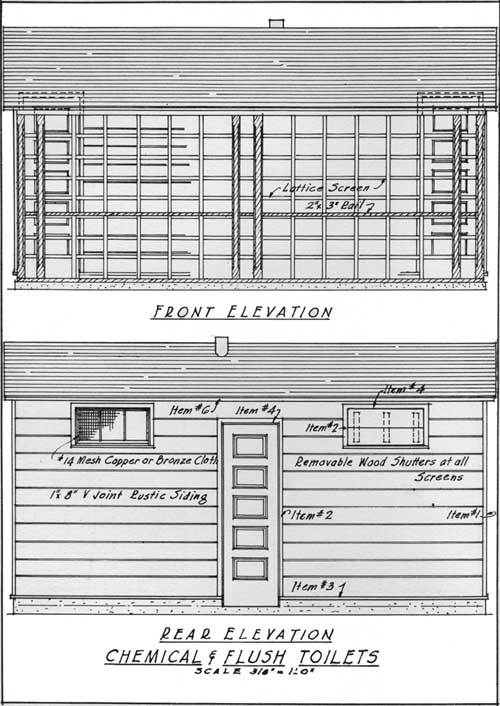

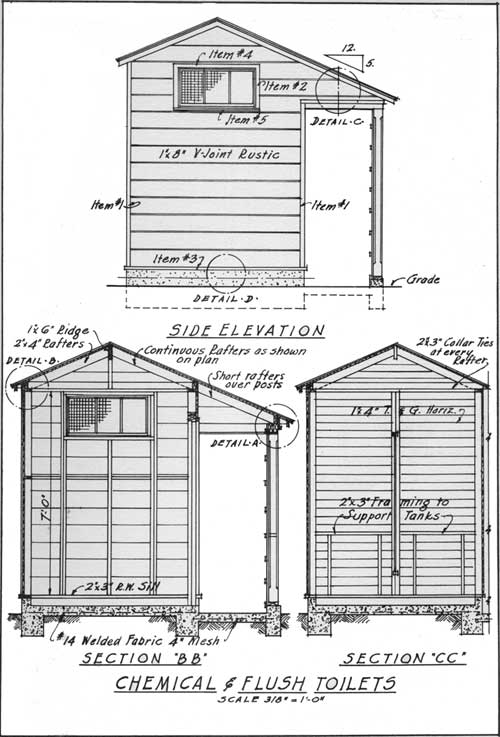

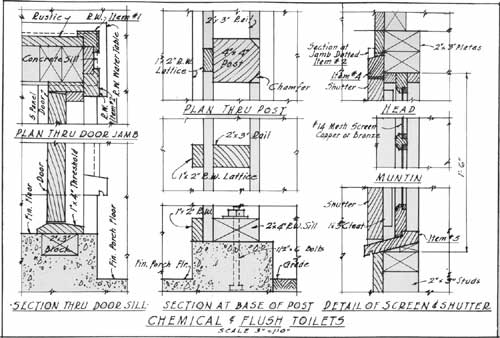

Chemcial Toilets

Chemical toilets should be installed only at public camps where there is acute danger of contamination of streams or other water supplies and where flush toilets cannot be used.

The theory underlying the chemical toilet is that certain alkalies, such as sodium hydroxide, will break down sewage to a liquid or sludge form, kill the bacteria, and reduce its potential health menace. One of their most disagreeable features is that such a chemical reaction produces odors which, if not actually offensive, are at least disagreeable. It is necessary to agitate the contents of the vaults or tanks frequently, to assure proper mixing of the sewage and the chemical.

Sodium hydroxide, the standard charging material used in chemical toilets, is a powerful reagent. It has strong caustic properties and will burn clothing or skin. When it is dissolved in water, a great deal of heat is generated. In charging chemical toilets, the danger of caustic burns must be borne in mind.

One or two pounds of sodium hydroxide should be dissolved in a pail of water (preferably a wooden bucket, because of the heat generated), and the solution poured into the tank. The operation is repeated until the entire charge has been dissolved. The chemical vaults shown on the following pages will require a charge of 50 pounds of chemical. Add water to about 250 gallons total.

The Angeles metal stool is to be used in all chemical toilets built hereafter, and designs shown in this Manual shall be adhered to in the construction of the buildings. Wherever permissible and practical, gravity outlets for removing wastes should be provided. Where this is not feasible, provision must be made for pumping the waste into a truck and removing it. Tanks should be emptied when the liquid rises to a point about 2 feet below the floor of the toilet.

Flush Toilets

As more adequate supplies of water are developed, more flush toilet systems are being installed in our forest camps. The flush systems are the safest and cleanest type of toilet. They do present difficulties, however. In the first place, a considerable quantity of water is used in day-to-day operation of a flush toilet at a public camp. Therefore, this type is not recommended for sites of limited water supply. They should not be installed where there is not proper drainage from the septic tank.

In all flush toilet installations, it is necessary to provide some means of treatment and disposal of the sewage. This is accomplished ordinarily by a septic tank installation, together with a leaching or filtering bed for disposal of the effluent from the tank. A septic tank is merely an airtight chamber into which wastes are run and held for a period, during which time bacteria operate to reduce the solids and render the solutions less harmful. The reaction is a natural one, no chemicals being required either to start it or to carry it on. Most septic tanks have two or more chambers, in which the material is acted upon to different degrees. The effluent from the tank is ordinarily clear and water-like, but is potentially very dangerous. It is found that the septic tank treatment does not kill such organisms as the typhoid germ. The effluent should never be run into streams, but should be carried through leaching systems, to percolate through the soil and be purified.

In the event that flush toilet systems be desired, detailed information regarding septic tanks may be secured from the Regional Office.

Flush toilets should be installed in buildings as shown in the Manual. It is recommended that frostproof bowls be used in camp flush toilet systems.

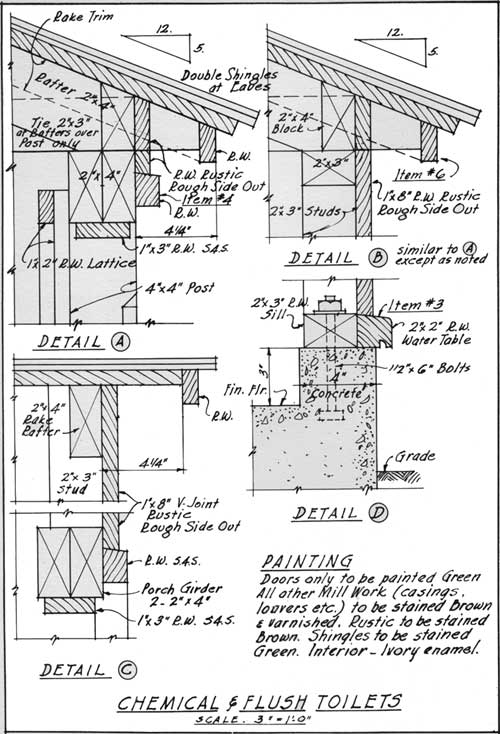

MATERIAL LIST FOR CHEMICAL OR FLUSH TOILET

| Concrete Aggregate - | 4 cu. yds. concrete mix |

| Cement | 15 sacks |

| Concrete pit is not included. Form lumber is not included. | |

Framing Lumber

| Mudsills | 2x3 | Redwood or Red Cedar #1 Heart Common | (2 pcs. (2 pcs. | 16-0 14-0 |

| 2x4 | same | 1 pcs. | 18-0 | |

| Studs and Cripples | 2x3 | #1 Common Douglas Fir S1S1E | 34 pcs. | 14-0 |

| Trimmers | 2x3 | same | 2 pcs. | 14-0 |

| Plates | 2x3 | same | (2 pcs. (2 pcs. | 18-0 12-0 |

| Collar Ties | 2x3 | same | (9 pcs. | 6-0 |

| 2x3 | same | (2 pcs. | 8-0 | |

| Eave Blocking | 2x4 | same | 3 pcs. | 18-0 |

| Rafters | 2x4 | same | 12 pcs. | 12-0 |

| Ridge Pole | 1x6 | same | 1 pcs. | 18-0 |

| Stud Blocking | 2x3 | same | 5 pcs. | 14-0 |

| Roof Sheathing | 1x6 | #2 Douglas Fir or #3 Ponderosa Pine Common Shiplap | 240 B.M. | |

| Porch Posts | 4x4 | #1 Heart Common Redwood or Red Cedar S4S | 6 pcs. | 6-0 |

| Porch Girder | 2x4 | #1 Common Douglas Fir S1S1E | (2 pcs. (2 pcs. | 18-0 6-0 |

| Porch Rail | 2x3 | #1 Heart Common Redwood or Red Cedar S4S | 1 pcs. | 18-0 |

| Lattice | 1x2 | same | (8 pcs. (9 pcs. | 14-0 18-0 |

| Rustic | 1x8 | V-jointed, clear all heart, unsurfaced "V"ed Redwood or Red Cedar Rustic, rough side out | 24 pcs. 14 pcs. 28 pcs. | 8-0 14-0 6-0 |

| Corner Beads | Item #1 | Clear All Heart Redwood or Red Cedar, milled to detail | 4 pcs. | 8-0 |

| Casings | Item #2 | same | 4 pcs. | 14-0 |

| Watertable | Item #3 | same | (2 pcs. (1 pcs. | 14-0 16-0 |

| Head Casing and Girder Trim | Item #4 | same | (3 pcs. (1 pcs. | 8-0 18-0 |

| Window Sills | Item #5 | same | 1 pcs. | 14-0 |

| Eave Trim | Item #6 | same | 2 pcs. | 18-0 |

| Girder Soffit | 1x3 | same S4S | (1 pcs. (1 pcs. | 18-0 6-0 |

| Rake Trim | 1x3 | Clear All Heart Redwood or Red Cedar | 2 pcs. | 12-0 |

| Door Frames | 1x3 | Clear Douglas Fir S4S | 3 pcs. | 16-0 |

| Door Stops | 3/4x1-1/4" net | same | 3 pcs. | 16-0 |

| Screen Stops | 1x1 | Clear All Heart Redwood or Red Cedar S4S | 8 pcs. | 6-0 |

| Shutter Stock | 1-1/4x8-1/4" net | same S1S1E | 4 pcs. | 6-0 |

| Doors | 3 doors 2-0 x 6-8 x 1 3/8" stock. 5 solid raised panels. | |||

| Toilet Doors | 4 doors 2'-2"x4'-8"x1-3/8" single panel. | |||

| Screens | 4 screens 3'-0"x1'-6"x7/8" - 3 lights as per detail. Screened with 16-mesh copper or bronze wire cloth. | |||

| Partition Stock | 1x4 | C Grade Douglas Fir or Ponderosa Pine, V-jointed, T.&G. Ceiling | (14 pcs. (28 pcs. | 10-0 12-0 |

| Partition Rails | 2x3 | #1 Common Douglas Fir S4S | (2 pcs. (2 pcs. | 8-0 10-0 |

| Partition Posts | 2x6 | same | 6 pcs. | 7-0 |

| Quarter Round | 3/4" | Douglas Fir or Ponderosa Pine | 8 pcs. | 10-0 |

| Shingles | Clear 100% edge grain Redwood or Red Cedar 16" 5/2 butts 2-1/2 squares 10 bundles | |||

Hardware

| Bolts Mudsill | 24 1/2"x6" machine bolts with nuts and cut washers. |

| Nails | 10 lbs. 16d common |

| 15 lbs. 8d common | |

| 10 lbs. 8d common galvanized | |

| 10 lbs. 3d shingle galvanized | |

| 5 lbs. 6d common | |

| 5 lbs. 6d finish | |

| Hinges | 3 pair 3-1/2"x3-1/2" wrought steel loose pin galvanized butts |

| 4 pair 3"x3" wrought steel loose pin butts | |

| 4 mortise door bolts, 1-3/4", equal to Russell-Irwin #13. | |

| 3 mortise lock sets, equal to Sargent Lock 5234, complete with knobs, trim, etc. | |

| 3 14" spring door closers, equal to Chicago #283. | |

| 4 coat and hat hooks. | |

| Mesh | 180 sq. ft. #14 gauge galvanized welded reinforcing mesh, wires spaced 4" on centers in each direction. |

| Paint | 2 gals. ivory enamel |

| 3 gals. grey green creosote shingle stain | |

| 5 gals. light weatherbeaten brown creosote stain | |

| 1 qt. green sash paint | |

| 2 qts. varnish | |

| 2 qts. turpentine |

|

| (click on image for a PDF version) |

|

| (click on image for a PDF version) |

|

| (click on image for a PDF version) |

|

| (click on image for a PDF version) |

|

| (click on image for a PDF version) |

| <<< Previous | <<< Contents>>> | Next >>> |

|

region/5/public-camp-manual/sec4-4.htm Last Updated: 11-Jan-2010 |